Preparation method of whitening complex protein peptide enzymatic hydrolysate, whitening complex protein peptide beverage and preparation method of whitening complex protein peptide beverage

A compound protein and peptide enzymatic hydrolysate technology is applied in the fields of whitening compound protein peptide drink, preparation of whitening compound protein peptide drink, and preparation of whitening compound protein peptide enzymolysis solution, which can solve the problem of poor effect, low utilization rate of digestion and absorption, etc. problem, to achieve the effect of good absorption, soothing fine wrinkles, and high water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

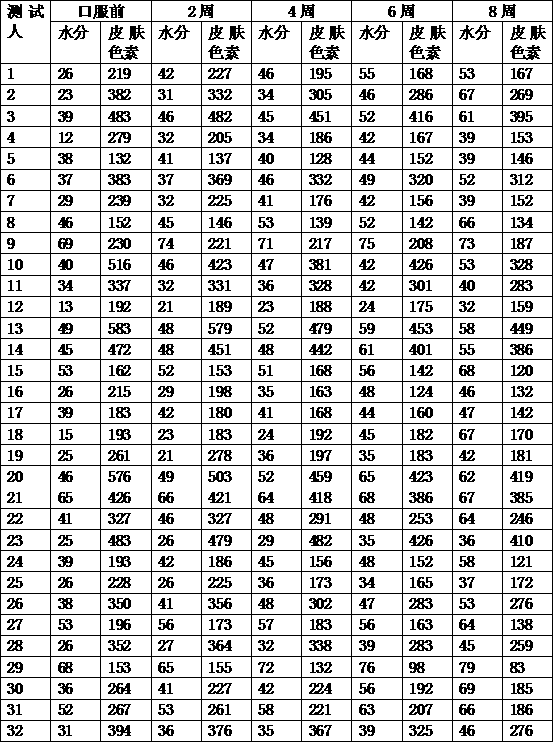

Image

Examples

Embodiment 1

[0070] In this embodiment, the preparation method of whitening complex protein peptide enzymatic hydrolyzate comprises the following steps:

[0071] (1) Based on dry weight, the following raw materials are prepared: 25% spirulina, 50% cod skin, 24% rice protein powder, and 1% bird's nest;

[0072] (2) Preparation of proteolysis solution

[0073] (2-1) Raw material pretreatment

[0074] (2-1a) Spirulina pretreatment

[0075] Spirulina is pulverized to obtain spirulina powder; then spirulina powder and purified water are mixed in a weight ratio of 1:6, and stirred evenly and then swelled (the mixture of spirulina powder and purified water is mixed at a speed of 50 rpm stirring; swelling at 50°C for 2 hours);

[0076] In this step (2-1a), the spirulina powder and purified water are added to the stainless steel tank, the stainless steel tank has a stirring system and a circulating water system; the stirring system is used to stir the materials in the stainless steel tank; the c...

Embodiment 2

[0115] In this example, the preparation method of the whitening compound protein peptide enzymatic hydrolyzate is the same as that in Example 1.

[0116] The whitening compound protein peptide drink of this embodiment contains the following components by weight: the whitening compound protein peptide enzymolyzate prepared according to the preparation method of the whitening compound protein peptide enzymolyzate in Example 1 is 8% based on the protein peptide content , erythrose 1%, honey 8%, γ-aminobutyric acid 0.2%, vitamin C 0.1%, raspberry extract 1.2%, ginseng extract 0.1%, yeast extract 3%, acerola fruit powder 2.5%, Rose juice powder 2%, peach fruit powder 1.5%, blueberry juice concentrate 2.5%, black currant juice concentrate 1.2%, malic acid 0.2%, citric acid 0.06%, pectin 0.1%, xanthan gum 0.05%, carboxymethyl cellulose Vegetarian sodium 0.1%, sucralose 0.03%, the balance is distilled water.

[0117] In this embodiment, the preparation method of the whitening complex...

Embodiment 3

[0124] In this embodiment, the preparation method of whitening complex protein peptide enzymatic hydrolyzate comprises the following steps:

[0125] (1) Based on dry weight, the following raw materials are prepared: 30% of spirulina, 54% of cod skin, 15.5% of rice protein powder, and 0.5% of bird's nest;

[0126] (2) Preparation of proteolysis solution

[0127] (2-1) Raw material pretreatment

[0128] (2-1a) Spirulina pretreatment

[0129] Spirulina is pulverized to obtain spirulina powder; then spirulina powder and purified water are mixed in a weight ratio of 1:8, and swelled after stirring evenly (the mixture of spirulina powder and purified water is mixed at a speed of 50 rev / min. stirring; swelling at 55°C for 2 hours);

[0130] In this step (2-1a), the spirulina powder and purified water are added to the stainless steel tank, the stainless steel tank has a stirring system and a circulating water system; the stirring system is used to stir the materials in the stainles...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com