Built-in micro-interface papermaking wastewater treatment system and method

A papermaking wastewater and treatment system technology, which is applied in the direction of processing wastewater treatment, water/sewage treatment, biological water/sewage treatment, etc., can solve the problem of high reaction temperature, small gas-liquid interface area and insufficient mass transfer time in wet oxidation method To achieve the best treatment effect, fully satisfy the mass transfer space, and improve the mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

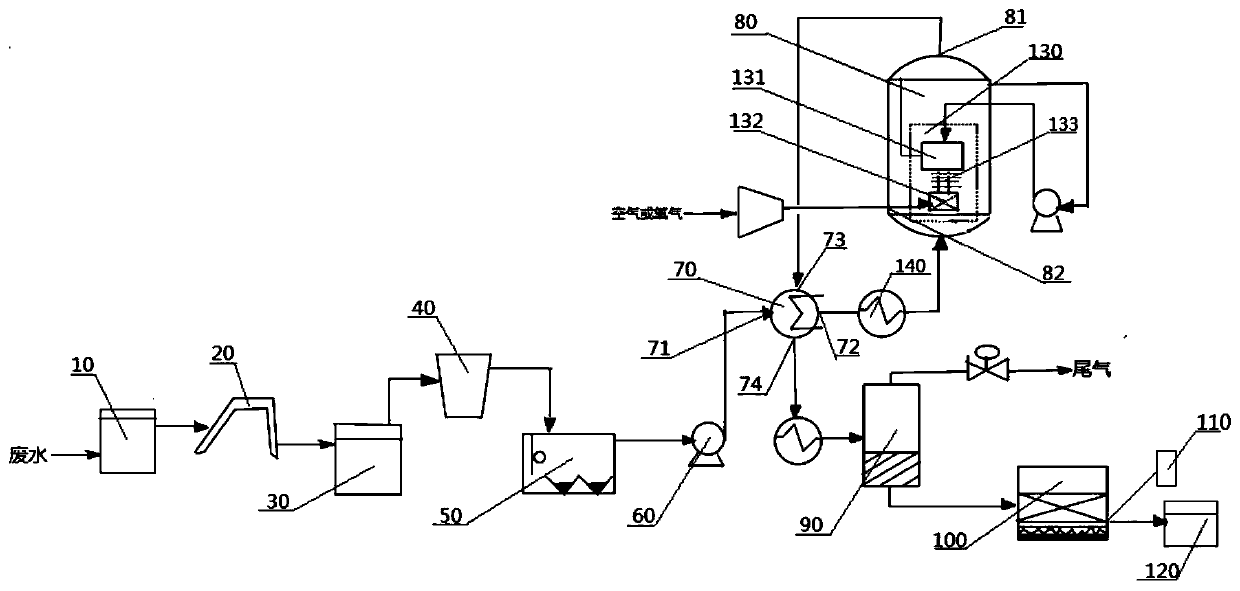

[0054] refer to figure 1 As shown, it is a treatment system for papermaking wastewater with a built-in micro interface according to an embodiment of the present invention, including a papermaking wastewater tank 10, a grid decontamination machine 20, a regulating tank 30, a centrifugal filter 40, a sedimentation tank 50 and a heat exchanger connected in sequence 70. Preheater 140, wet oxidation reactor 80, gas-liquid separator 90, biodegradation tank 100; wherein, the heat exchanger 70 is provided with a first inlet 71, a first outlet 72, a second inlet 73, a second Outlet 74, the sedimentation tank 50 is connected to the first inlet 71 through the booster pump 60, and the first outlet 72 is connected to the bottom of the wet oxidation reactor 80 through the preheater 140. After the waste water is heat exchanged, it enters the wet oxidation reactor Preheating before 80, the top of the wet oxidizer 80 is provided with an oxidation outlet 81, the oxidation outlet 81 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com