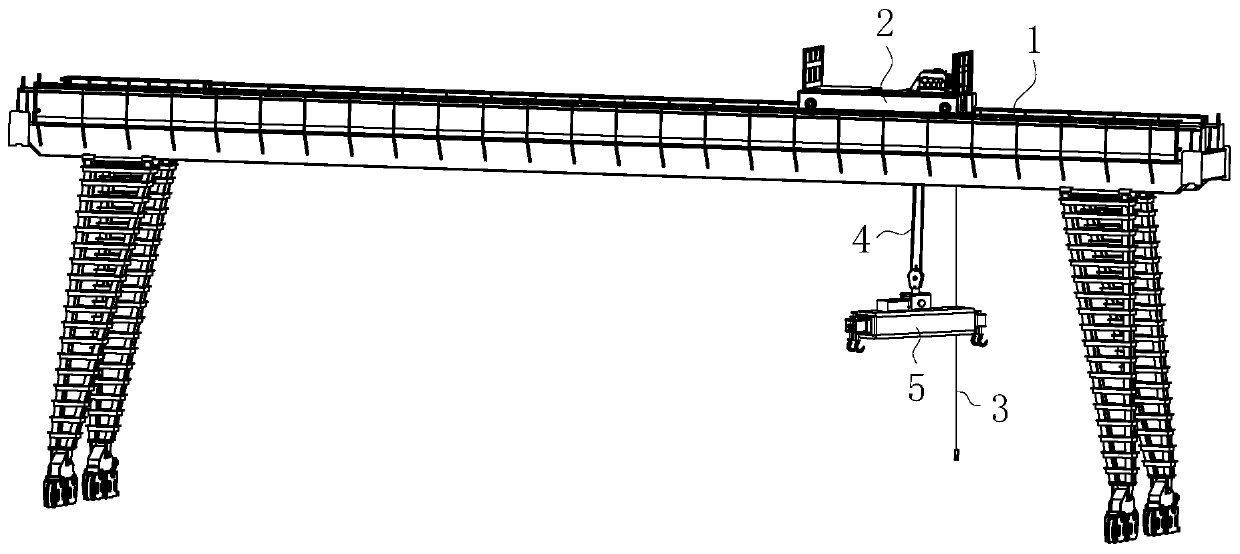

Hoisting device for bridge construction

A technology for hoisting equipment and bridge construction, applied in transportation and packaging, load hoisting components, cranes, etc., can solve problems such as long length, sliding friction between hoisting bandages and hoisting objects, affecting the stability and safety of hoisting objects, etc. The effect of preventing tilt or unstable center of gravity, improving stability and safety, and reducing the length of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

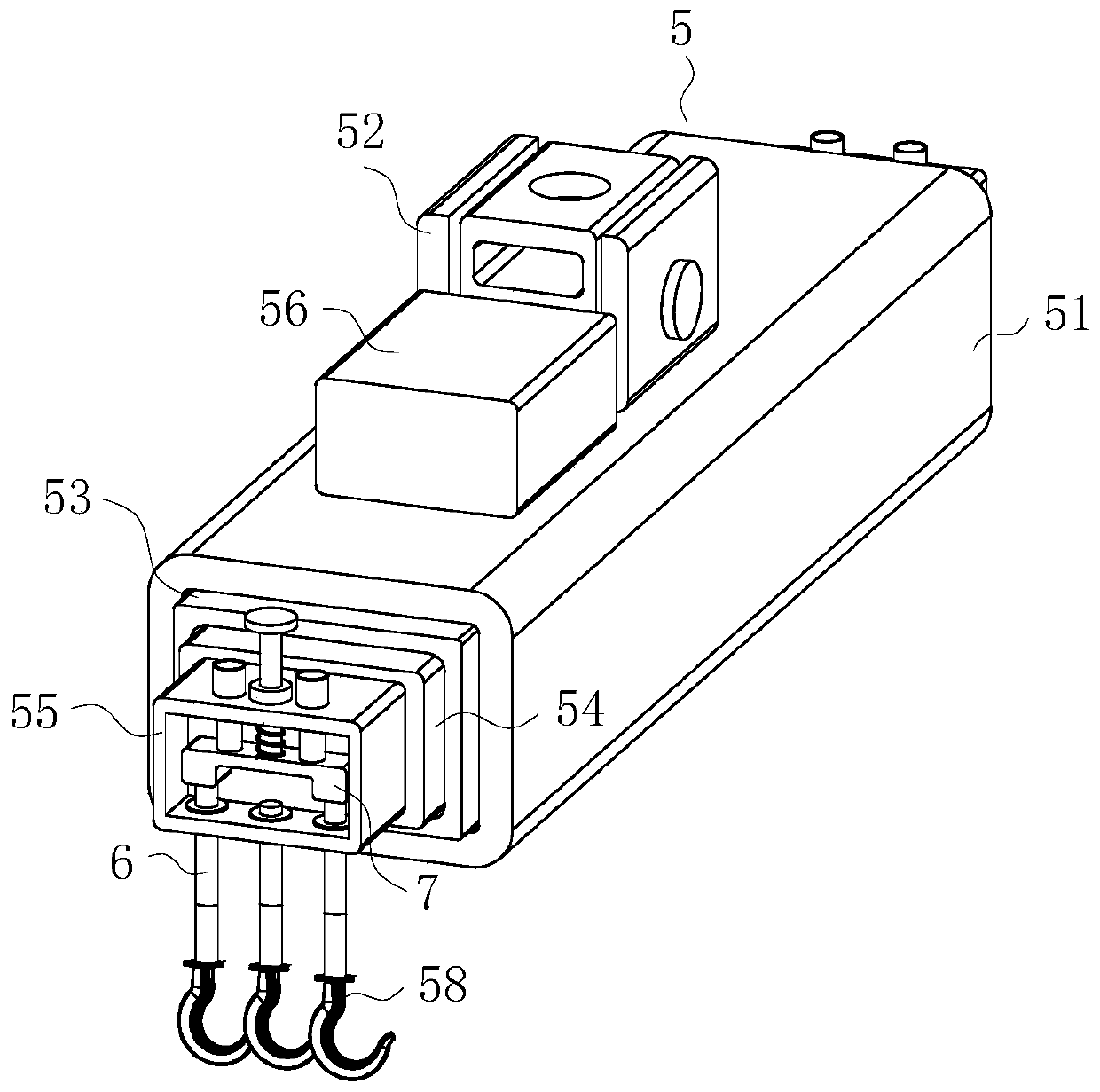

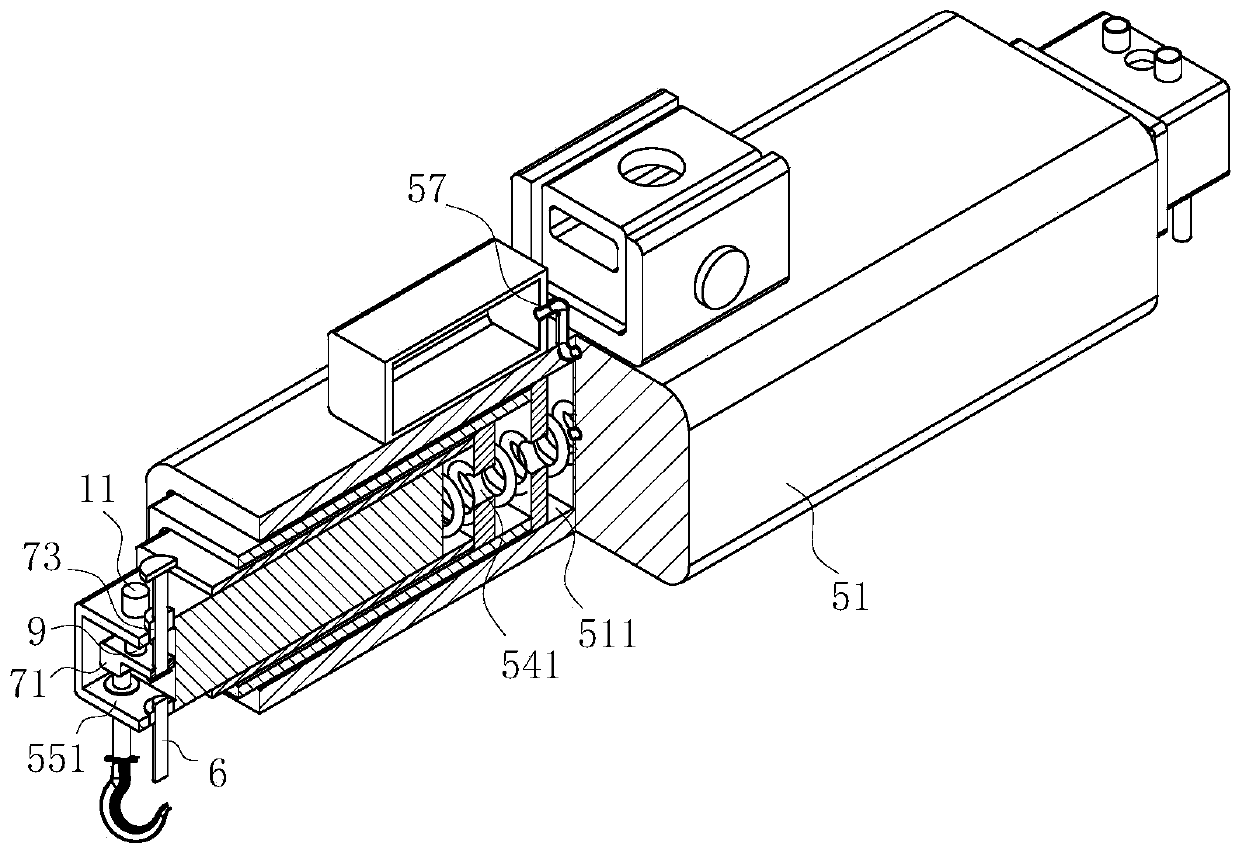

[0026] As an embodiment of the present invention, the lifting adjustment mechanism 7 includes an I-shaped connecting plate 71, a rotating screw 72, a screw sliding sleeve 73, a fixed block 74 and a limit spring 75; the third beam arm 55 An installation cavity 551 is provided at the end of the installation cavity 551, and an I-shaped connecting plate 71 is movable; the left and right bottom ends of the I-shaped connecting plate 71 are fixedly connected to the connecting rod 6; the rotating screw rod 72 rotates through the upper chamber wall of the installation chamber 551 through the screw mandrel sliding sleeve 73, and the top end of the rotating screw mandrel 72 is located outside the installation chamber 551; the bottom end of the rotating screw mandrel 72 passes through the I-shaped connecting plate 71 The fixed block 74 is rotationally connected with the I-shaped connecting plate 71; the upper end surface of the I-shaped connecting plate 71 is connected to the upper cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com