Cart - Track Conveyor with Integral Connection Reversal

A track conveyor, integrated technology, applied in the direction of conveyor, mechanical conveyor, transportation and packaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

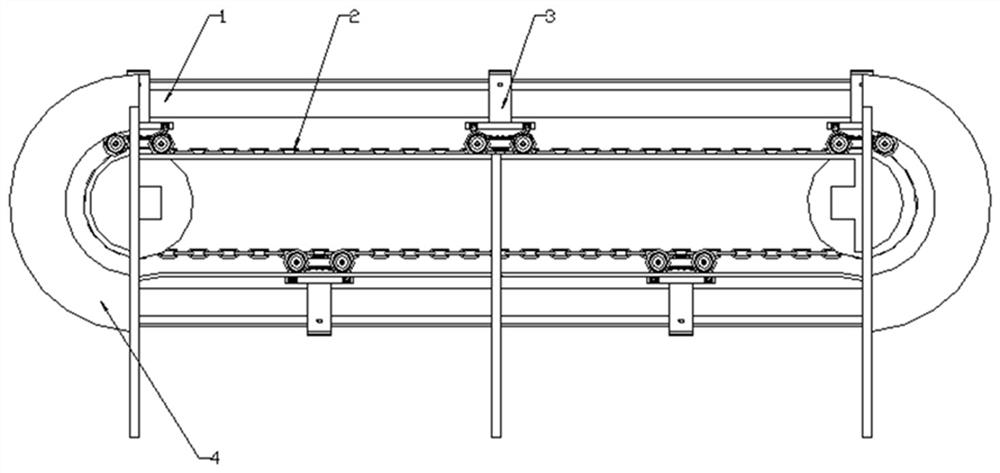

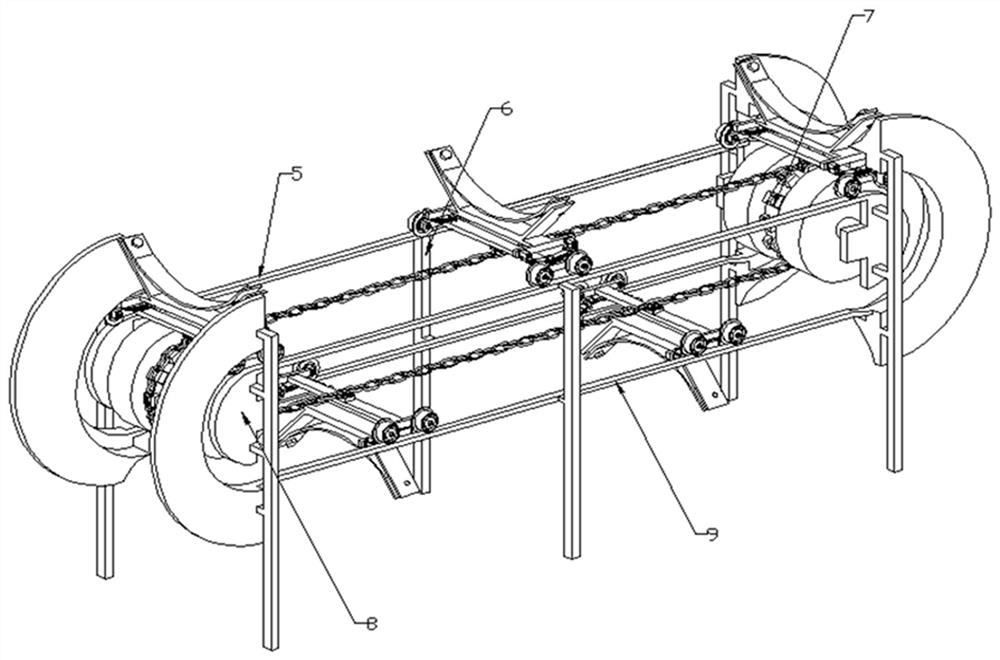

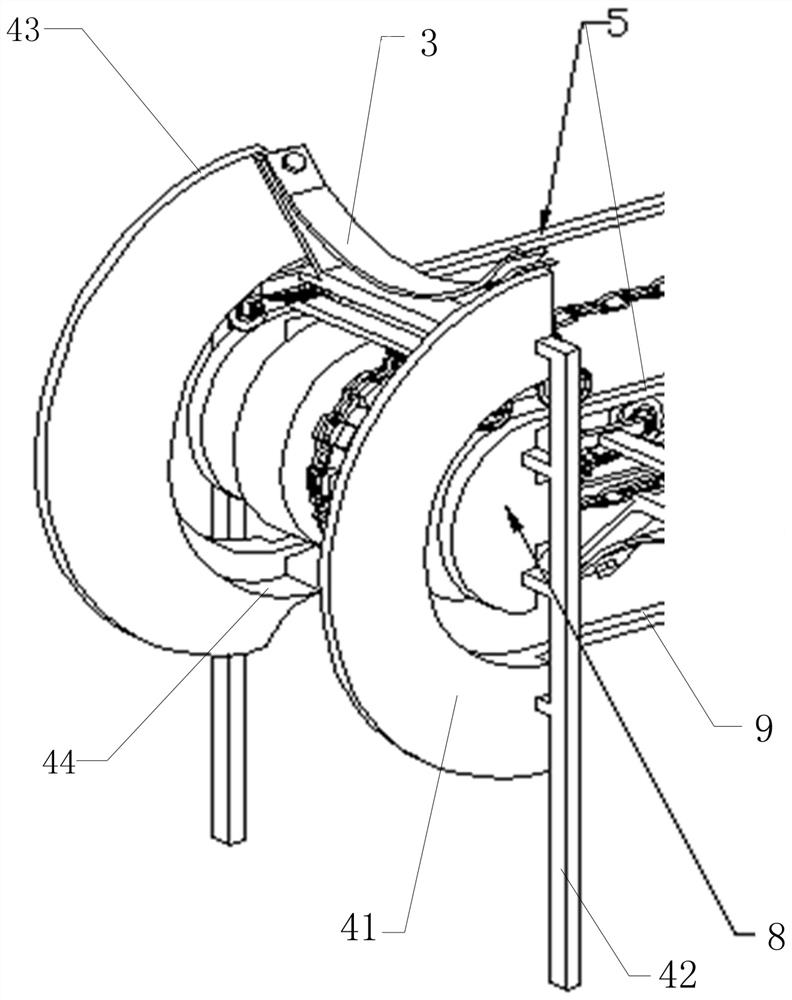

[0043] Such as figure 1 and 2 The track conveyor shown includes four parts: a load-bearing frame, a load-bearing track, a transmission device and a wheeled functional element.

[0044]The bearing frame is composed of a head reversing bracket, a tail reversing bracket and a track bracket (6). The bearing rails, the transmission device and the corresponding functional elements are installed and arranged on the frame. The load-carrying track consists of an ascending track (5), a descending track (9), an arc-shaped limit track for the nose, an arc-shaped limit track for the tail, an inner limit track for the nose reversing bracket, and an inner limit track for the tail reversing bracket. Composition, the arc-shaped limit track is adapted to the up track (5) and the down track (9), so that the wheels of the track trolley (3) can be smoothly converted between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com