Glass piece four-side polishing production line

A technology of glass parts and production line, which is applied in the field of four-side grinding production line of glass parts. It can solve the problems that the feeding mechanism cannot be used for glass transmission of different sizes and easily damaged glass, etc., and achieves the effects of improving positioning stability, wide application range and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

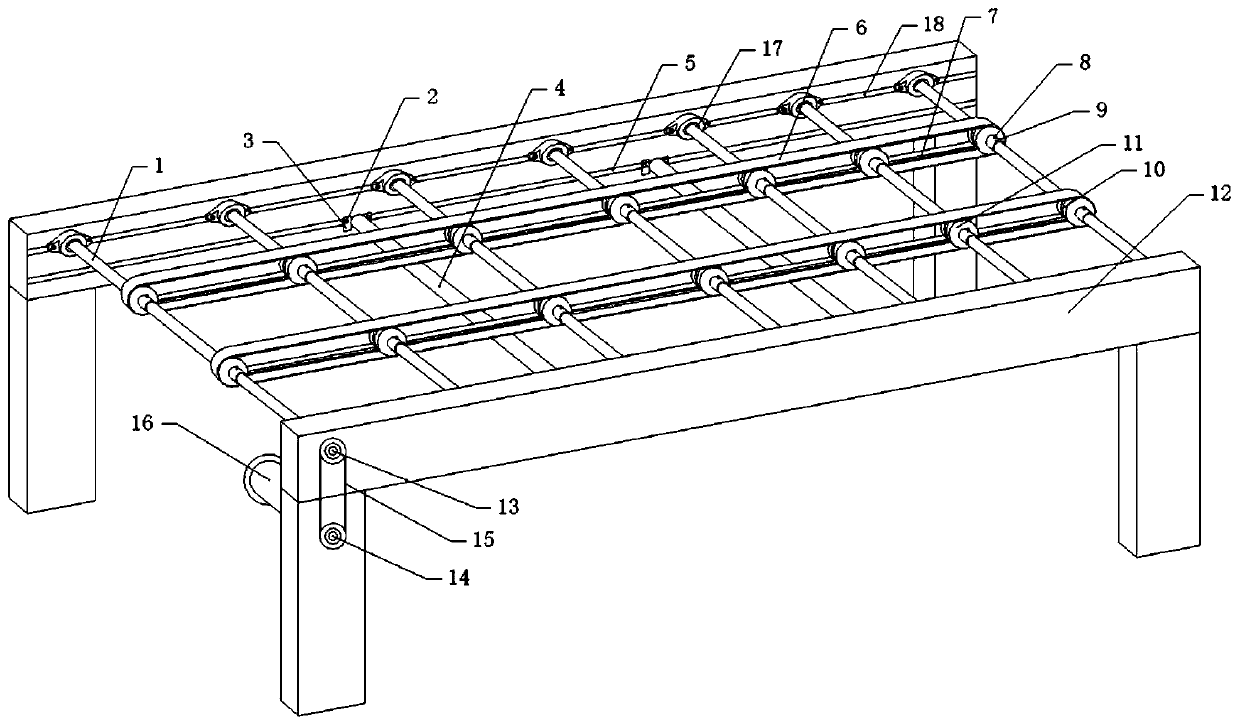

[0039] Such as figure 1 and figure 2 As shown, the four-side grinding production line for glass pieces includes a feeding mechanism, a first grinding mechanism and a second grinding mechanism. The feeding mechanism is installed at the feeding end of the first grinding mechanism to transport glass pieces (rectangular glass plates) to the first Grinding mechanism. The first grinding mechanism is used for grinding one set of opposite sides of the glass piece, and the second grinding unit is used for grinding another set of opposite sides of the glass piece.

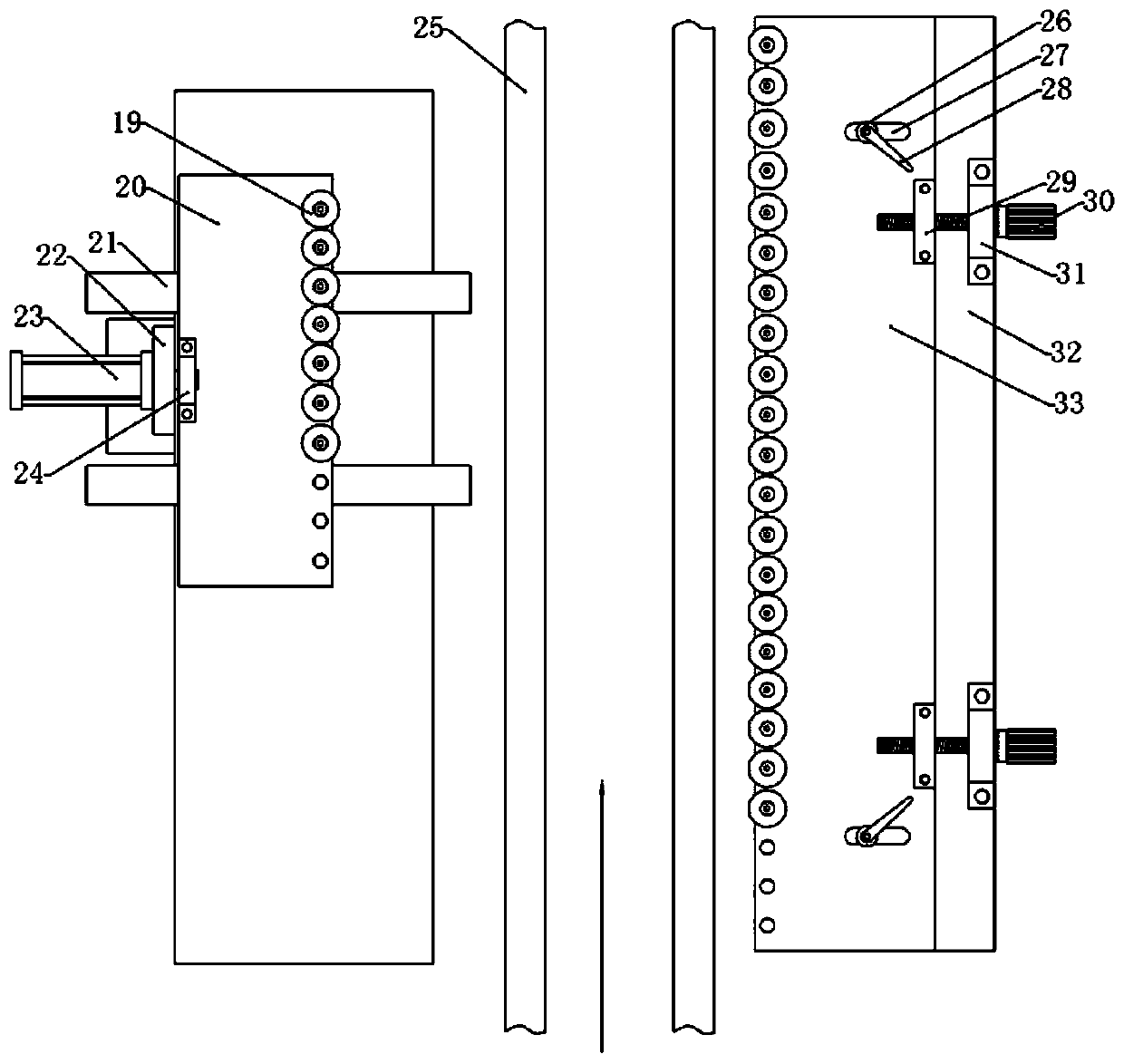

[0040] Both the first grinding mechanism and the second grinding mechanism comprise an upper transmission belt and a lower transmission belt 25 ( figure 2 Only the lower conveyor belt 25 is shown in the figure), the upper conveyor belt and the lower conveyor belt 25 are aligned in the vertical direction, and between the upper conveyor belt and the lower conveyor belt 25 is a transmission space for transmitting glass part...

Embodiment 2

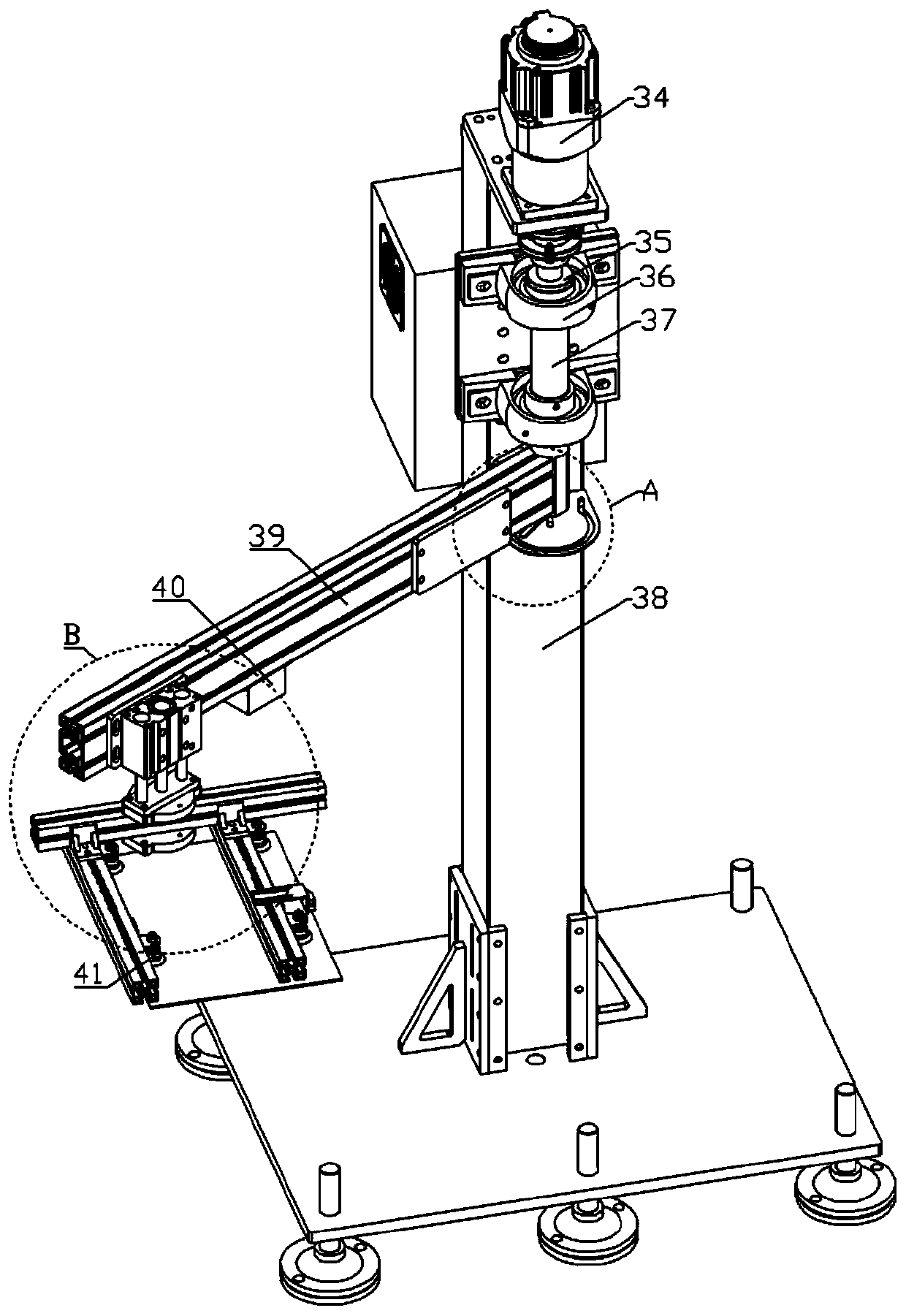

[0060] Such as Figure 3-Figure 5As shown, the difference between this embodiment and the first embodiment is that it also includes a transfer mechanism for transferring the glass piece from the first grinding mechanism to the second grinding mechanism. The material transfer mechanism comprises a support 38 and a rotating arm 39, and the drive mechanism for driving the rotating arm 39 to rotate is installed on the support 38. The driving mechanism includes a material transfer motor 34 and a rotating shaft 37 connected with the transfer motor 34, and the transfer motor 34 is fixed on Support 38 tops; Rotating shaft 37 is vertically arranged, and rotating shaft 37 is fixedly connected with the output shaft of turning material motor 34, and the right end of rotating arm 39 is fixedly connected with the bottom of rotating shaft 37 by bolt. Two fixed sleeves 36 are fixed on the bracket 38 by bolts, and the rotating shaft 37 is rotatably connected in the two fixed sleeves 36 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com