Processing technology of seamless drill pipe

A processing technology, seamless drill pipe technology, applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of low service life, difference in mechanical properties of seamless drill pipe, high scrap rate of seamless drill pipe, etc., to improve Effect of service life and reduction of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

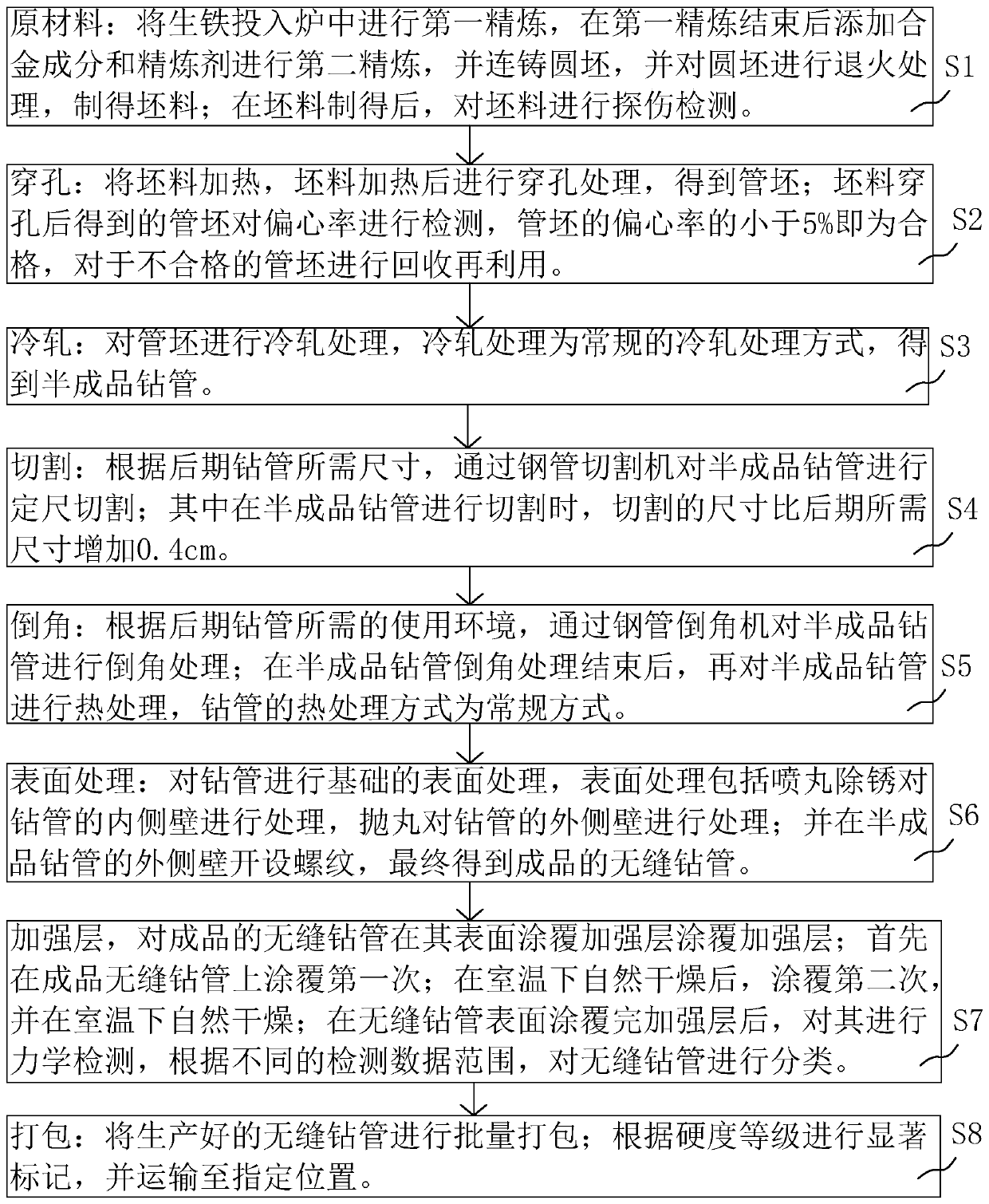

[0039] refer to figure 1 , is a kind of processing technology of seamless drill pipe disclosed by the present invention, comprises the following steps:

[0040] S1. Raw materials: put pig iron into the furnace for the first refining, add alloy components and refining agents for the second refining after the first refining, and continuously cast round billets, and perform annealing treatment on the round billets to obtain billets; The alloy composition is Si, Sn, Bi, In and Nb;

[0041] After the blank is produced, flaw detection is performed on the blank, preferably a physical flaw detection method, and mark removal treatment is performed on damaged parts.

[0042] S2, perforation: heating the billet, the heating temperature is controlled at 1150°C, after the billet is heated, it is perforated to obtain a tube blank;

[0043] The eccentricity of the tube blank obtained after the blank is pierced is tested. If the eccentricity of the tube blank is less than 5%, it is qualifie...

Embodiment 2

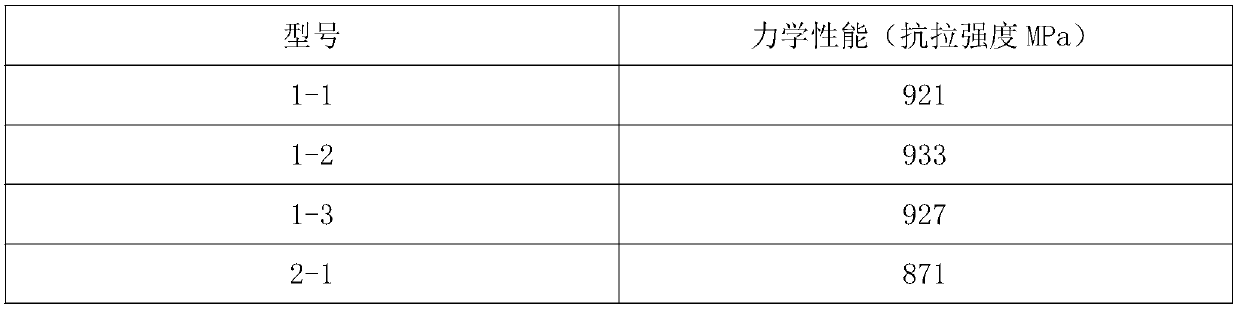

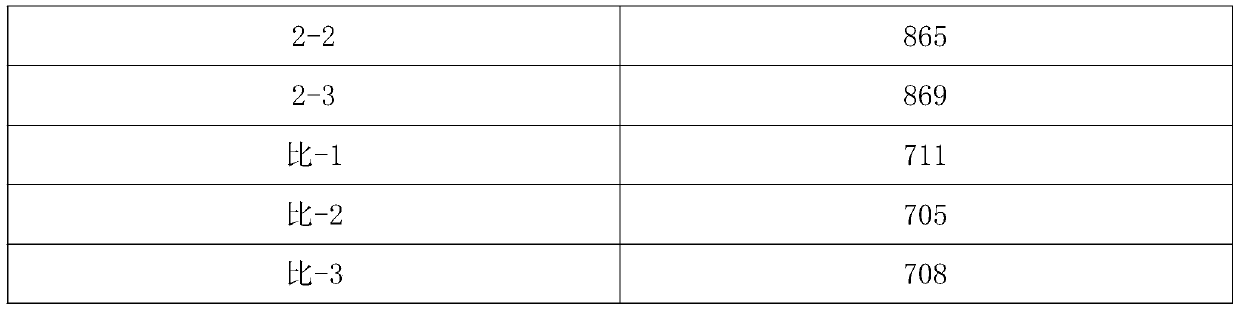

[0057] The difference between this embodiment and Embodiment 1 is that in step S7, only one reinforcing layer is coated on the finished seamless drill pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com