Metal pipe fitting port sealing device

A technology of sealing device and metal pipe fittings, applied in the field of automatic rapid extrusion forming sealing device of muffler pipe, can solve the problems of generating arc fume, increasing raw material cost, many processes, etc., eliminating stamping and welding processes, diversifying control functions, Reduced operator effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

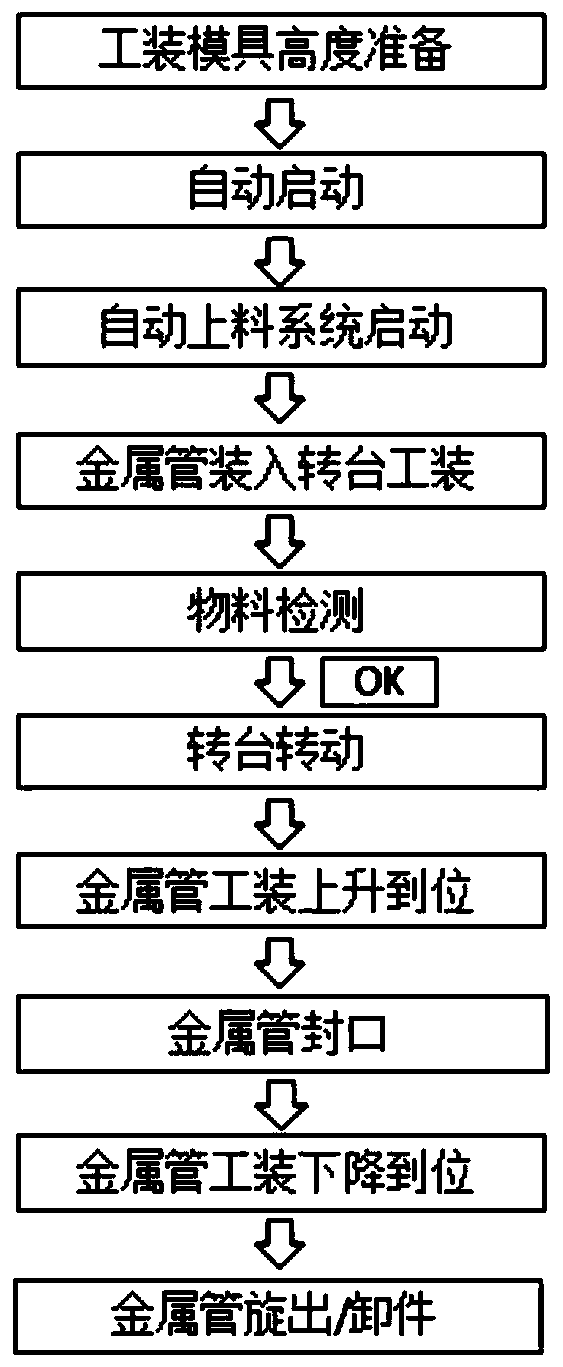

Method used

Image

Examples

Embodiment Construction

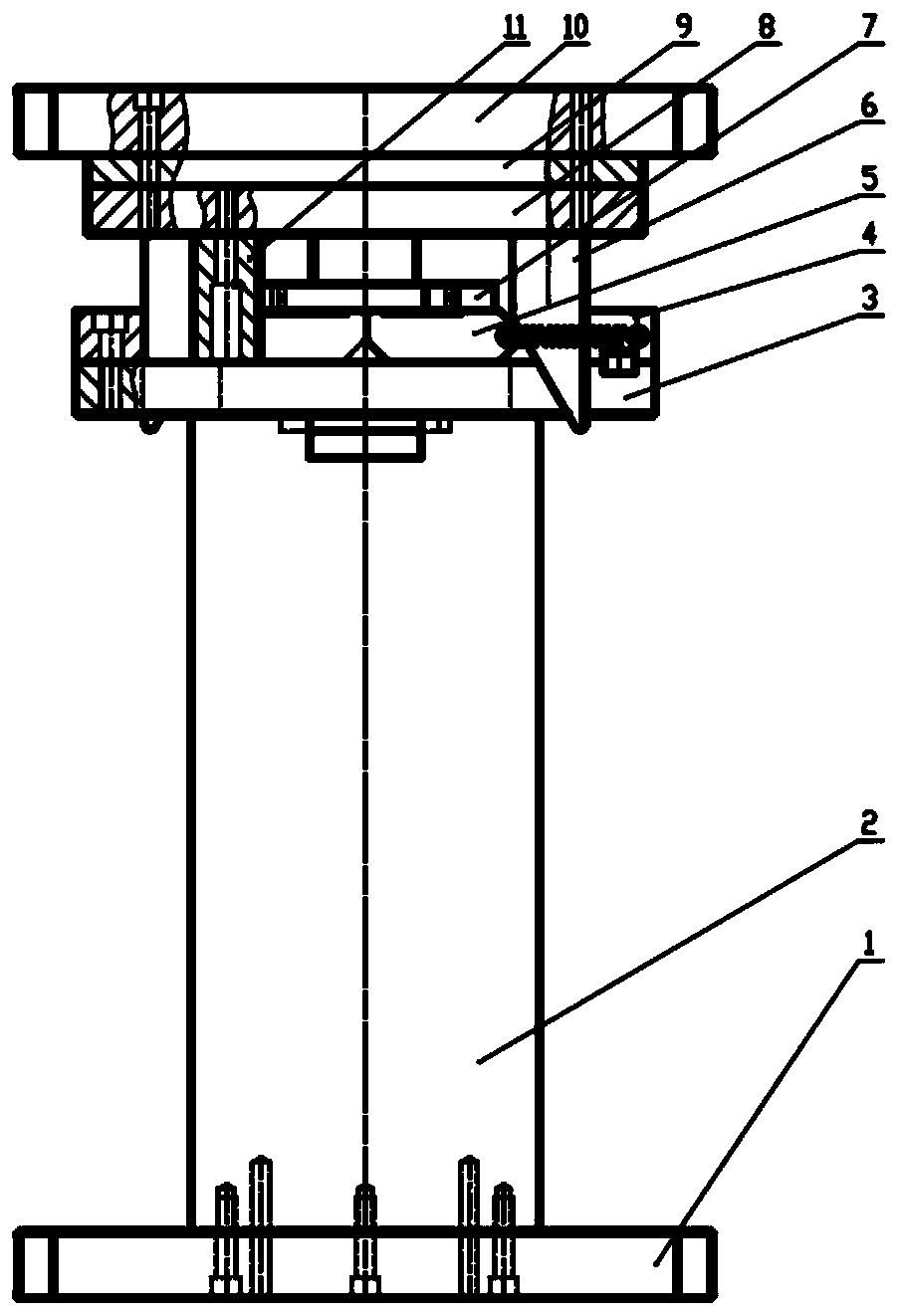

[0018] A metal pipe fitting port sealing device, used in conjunction with an intelligent sealing machine, includes an upper mold and a lower mold; the upper mold includes an upper mold mounting plate, a guide post, a guide post mounting seat, a support rod, a support rod mounting seat, a pipe fitting Positioning tooling, positioning tooling adjustment seat, the upper mold mounting plate is provided with first mounting holes, the number of the first mounting holes is two, and the first mounting holes are symmetrically distributed in the middle of the upper mold mounting plate , there are two positioning tool adjustment seats, the positioning tool adjustment seat is a hollow structure with a convex cross-section, the size of the positioning tool adjustment seat is in a cooperative relationship with the size of the first installation hole, and the positioning The tooling adjustment seat fits and is fixed in the first mounting hole, the pipe fitting positioning tooling is a cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com