Production equipment and production method of activated carbon-based soil remediation fertilizer

A technology for soil remediation and production equipment, which is applied in the direction of organic fertilizers, fertilizer mixtures, chemical instruments and methods, etc. It can solve the problems of reduced survival rate of bacteria, short shelf life of fertilizers, and failure to meet ideal standards, so as to improve the bacteria. The effect of survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

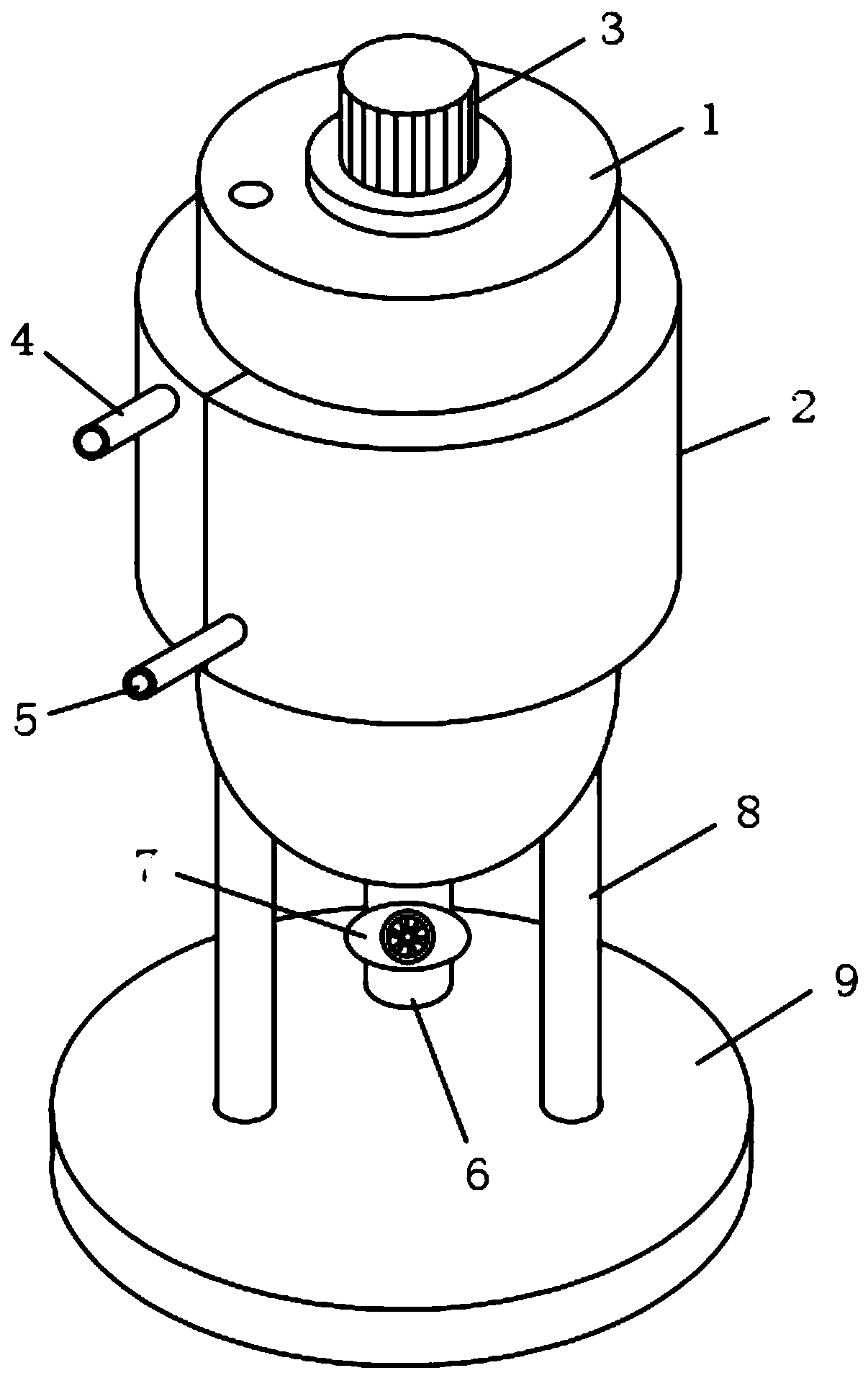

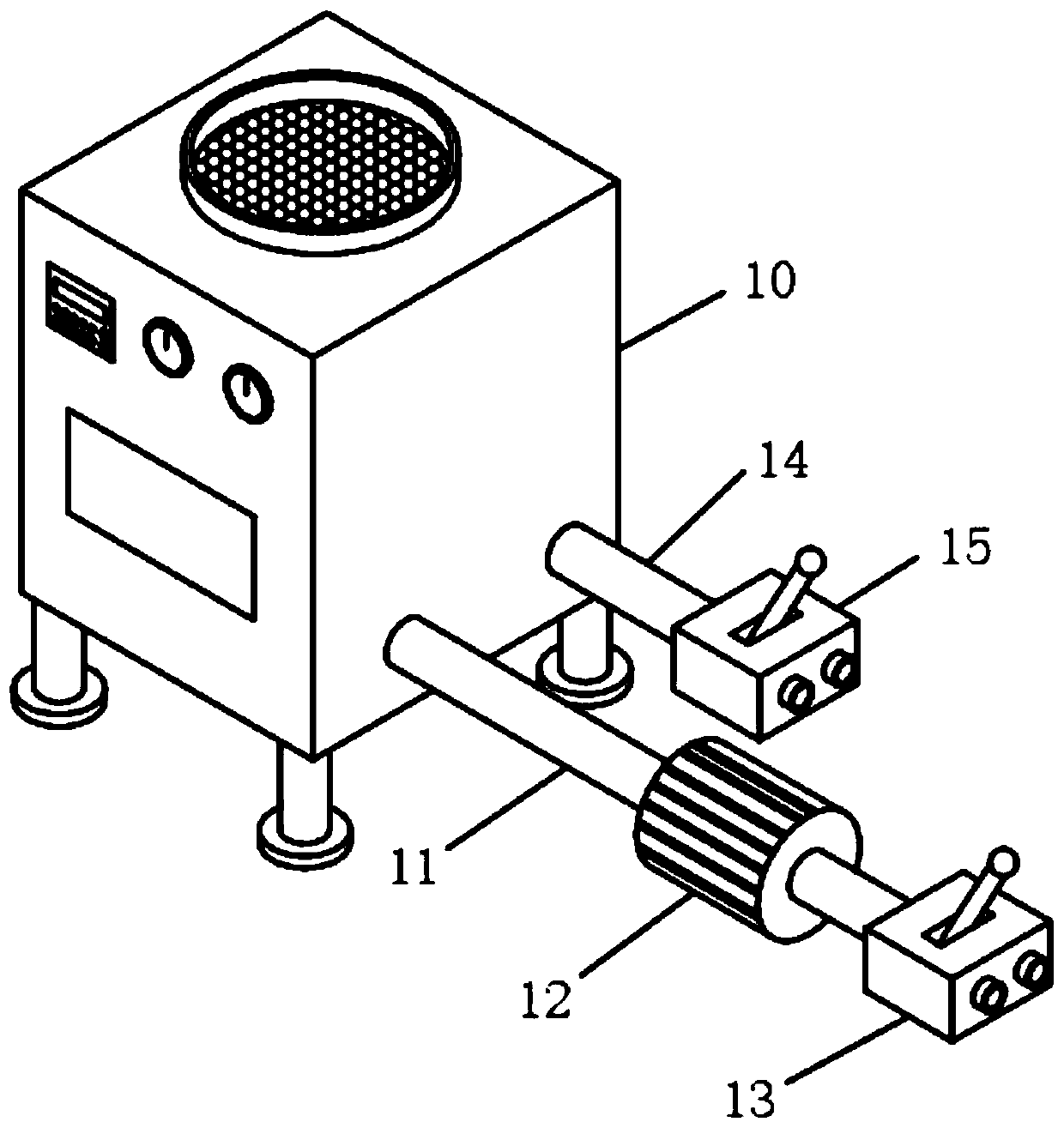

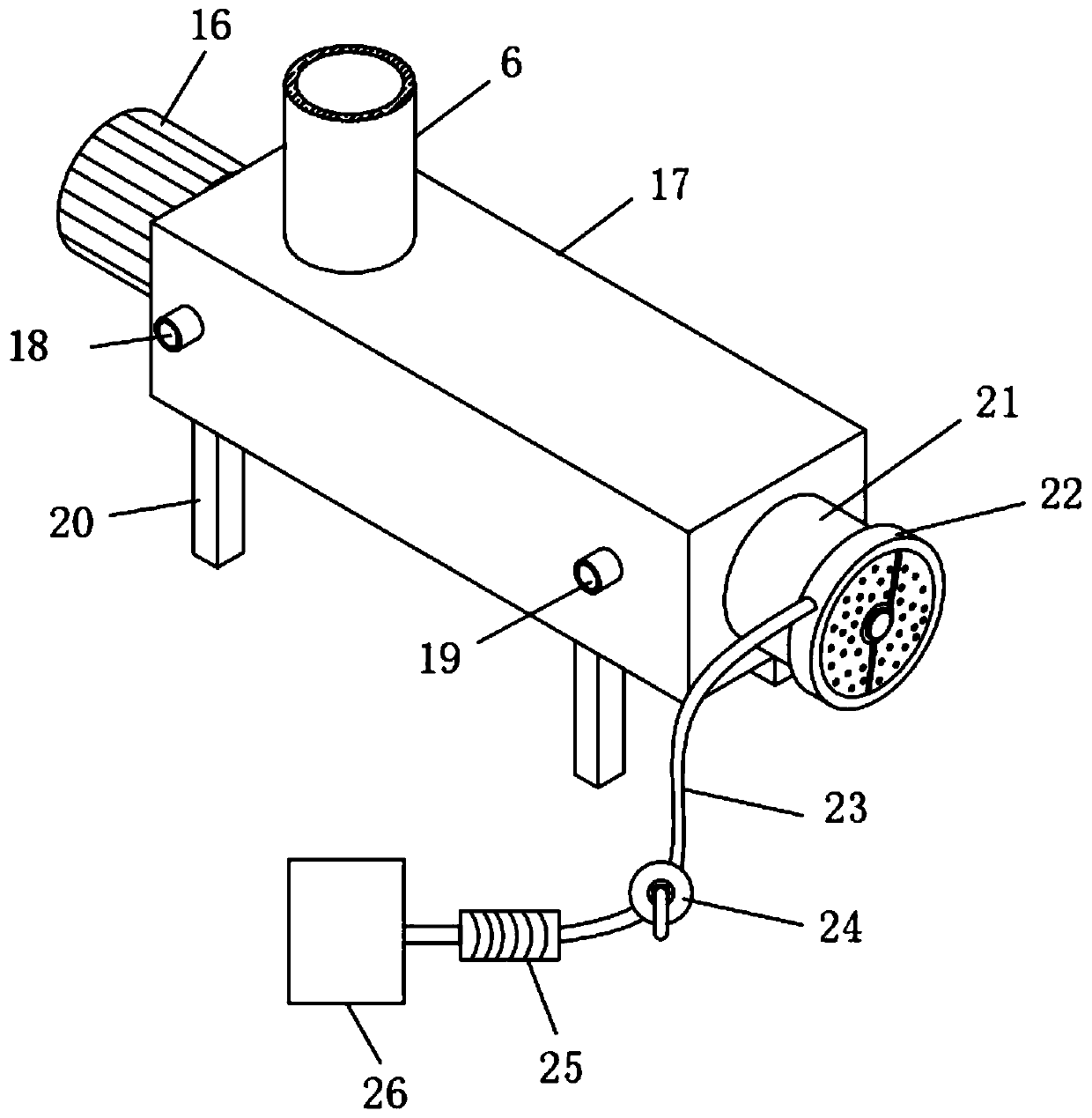

[0038] The present invention provides Figure 1-6 The shown production equipment of activated carbon-based soil remediation fertilizer includes: a mixing tank 1, the outer side of the mixing tank 1 is fixedly connected with a jacket 2, and the bottom of the mixing tank 1 is fixedly connected with a discharge pipe 6, and The discharge pipe 6 is equipped with a discharge valve 7; a refrigeration mechanism, the refrigeration mechanism includes a refrigerator 10, one side of the refrigerator 10 is connected with a first air pump 12 and a first reversing valve through an air outlet pipe 11 13, and one side of the refrigerator 10 is connected with the second reversing valve 15 through the air inlet pipe 14; an extrusion granulation mechanism, the extrusion granulation mechanism includes an extrusion cylinder 21, the outside of the extrusion cylinder 21 A heat-insulating housing 17 is also provided. One end of the extrusion cylinder 21 is fixedly installed with an extrusion motor 16 f...

Embodiment 2

[0047] Different from the attachment of anaerobic flora on biological activated carbon in Example 1, this example attaches aerobic microbial flora on biological activated carbon; therefore, the carbon dioxide gas storage tank is replaced with an oxygen gas storage tank, and the oxygen gas storage tank It contains a mixed gas of oxygen and nitrogen. The oxygen content is 30-45%, and the oxygen content is higher than that of the air, but it should not be too high. Too high can easily lead to accelerated aging of microorganisms, thereby reducing the survival rate of microorganisms , Resulting in a reduction in the shelf life of fertilizers.

Embodiment 3

[0049] Different from the attachment of anaerobic flora on biological activated carbon in Example 1, this example attaches anaerobic microbial flora on biological activated carbon; therefore, the carbon dioxide gas storage tank is replaced with a nitrogen gas storage tank, and the nitrogen gas storage tank It contains a mixed gas of oxygen, nitrogen and carbon dioxide, wherein the oxygen content is 5-10%, the nitrogen content is 90-95%, and the carbon dioxide content is less than 1%.

[0050] In summary: the above three groups of embodiments can reasonably adjust the gas composition according to the type of bacteria, so as to create a suitable environment during granulation. The present invention realizes the jacketing of the mixing tank and the extrusion cylinder through a set of refrigerators. Switching refrigeration during use makes the biological activated carbon at a relatively low temperature during the mixing and extrusion granulation process, avoiding the high temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com