Method for making low-sugar rice with cooking utensil

A technology for cooking utensils and production methods, applied to the structure of cooking utensils, steam cooking utensils, cooking utensils, etc., which can solve the problems of high sugar content in rice, reducing the taste of rice, and large water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

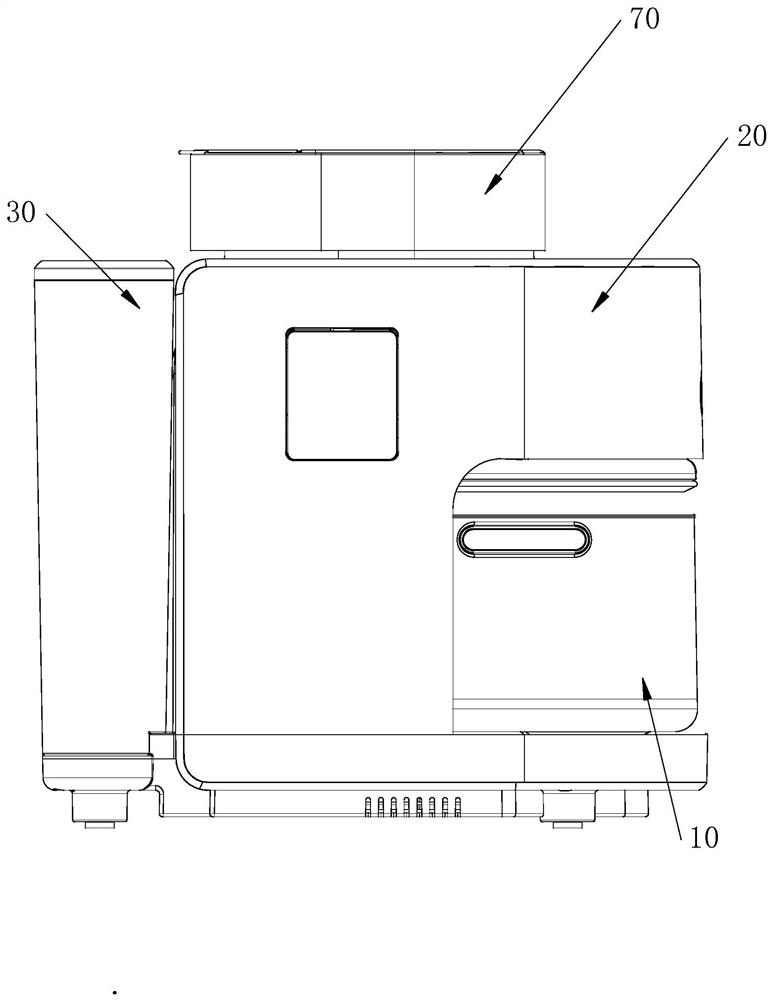

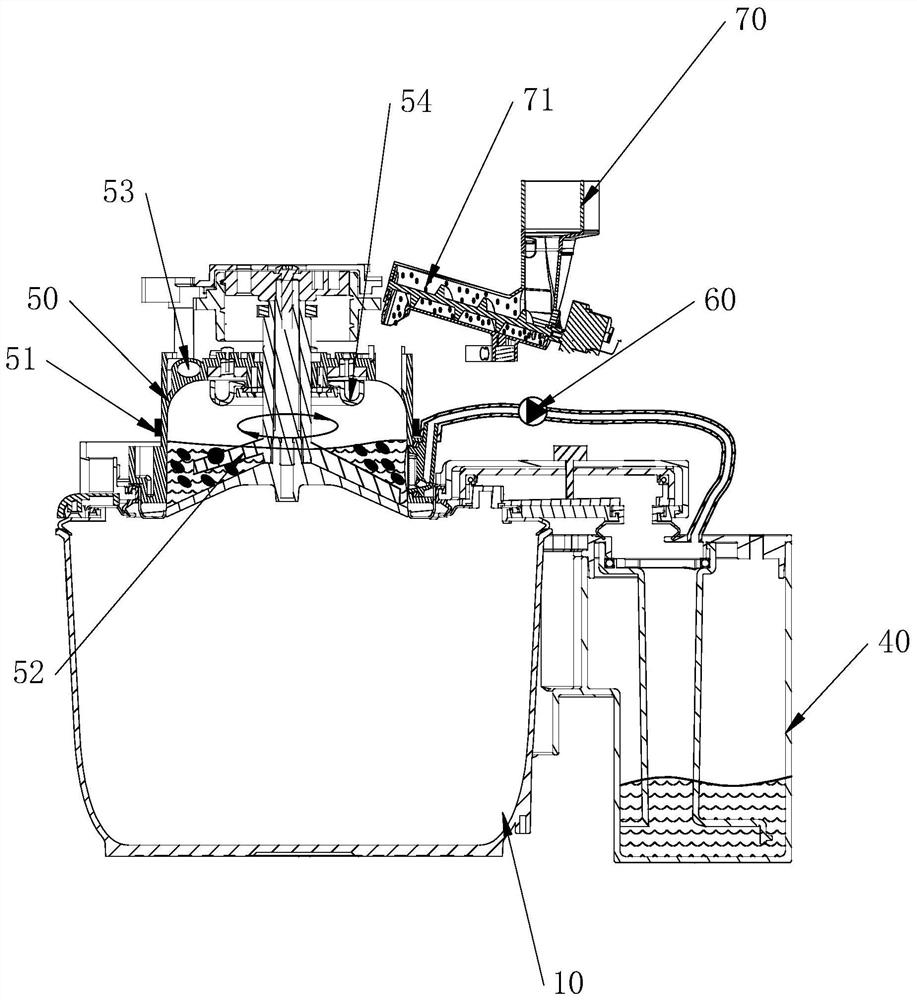

[0039] like figure 1 , 2 As shown in and 5, in this embodiment, the cooking appliance includes a pot body 10, a cover body 20 provided on the pot body 10, a heating device (not shown in the figure) for heating the pot body, a water tank 30 and a waste water tank 40. The cover body 20 is provided with a rice washing bin 50 opposite to the pot body 10. The outer wall of the rice washing bin 50 is provided with a heating element 51 for heating the rice washing bin. The rice washing bin 50 is provided with a stirring device 52. The water supply port 53 and the spray assembly communicated with the water supply port 53, the spray assembly is communicated with the water tank 30, the rice washing bin 50 is communicated with the waste water tank 40 through the water pump 60; the cover body 20 is provided with a rice storage bin 70, the The rice bin 70 conveys rice to the rice washing bin 50 through the feeding device 71, wherein the spray assembly includes a turbine spray disc 54 that...

Embodiment approach 2

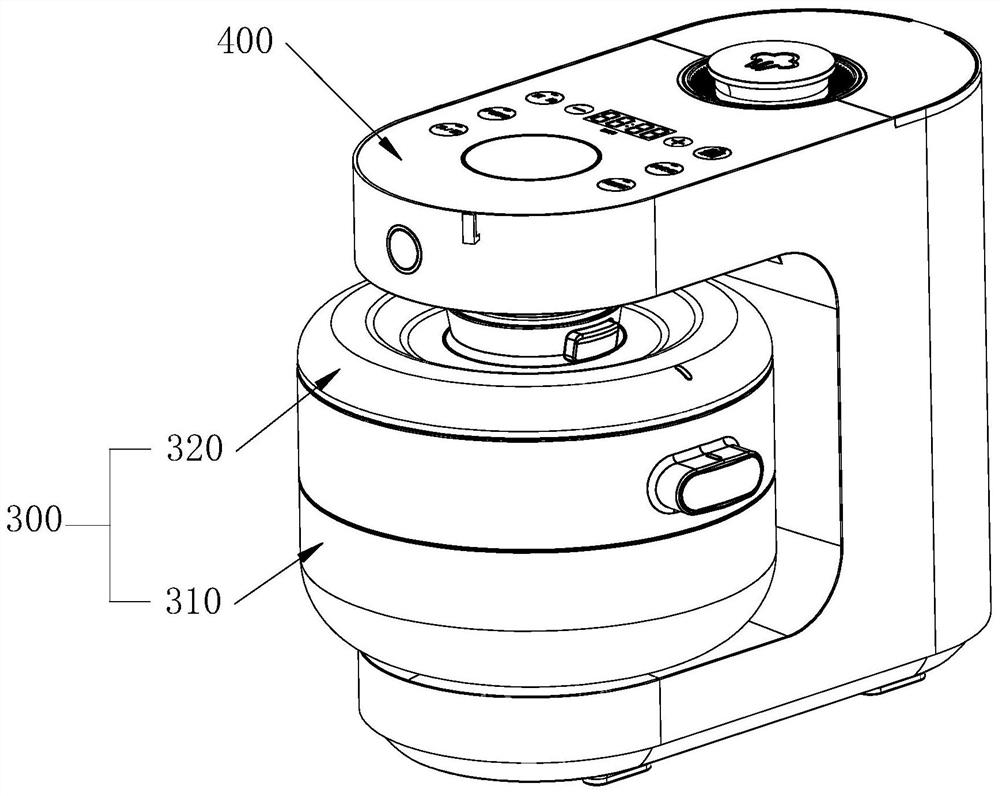

[0062] like image 3 and 4 As shown, in this embodiment, the cooking utensil is a steam heating type cooking utensil, and the steam heating type cooking utensil includes a pot 300 and a body 400 on which the pot 300 is placed. The water supply component 500 for steam, the water supply component 500 includes a water tank 520 and a steam generator 510, and the cookware 300 includes a pot body 310 and a pot cover 320 that is closed on the pot body 310. The pot cover 320 and the pot body 310 form a cooking accommodating food. In the cavity 330, a steamer 600 matching the pot body 310 is arranged in the pot body 310, and the steam generator 510 is docked with the pot cover 320 to feed water and / or steam into the pot body 310. The method for making low-sugar rice includes:

[0063] a. Starch elution stage: the water supply component 500 feeds water into the pot, so that the rice on the steamer 600 is first soaked at 50°C to 65°C for t1 time, and then soaked at 70°C to 90°C for t2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com