Battery structure with cover cap bracket

A cap and battery technology, applied to large-size batteries/battery packs, small-size batteries/battery packs, structural parts, etc., can solve the problems of small internal space capacity of batteries and unreasonable structural design, etc., to improve practicability , optimize the structure, increase the effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

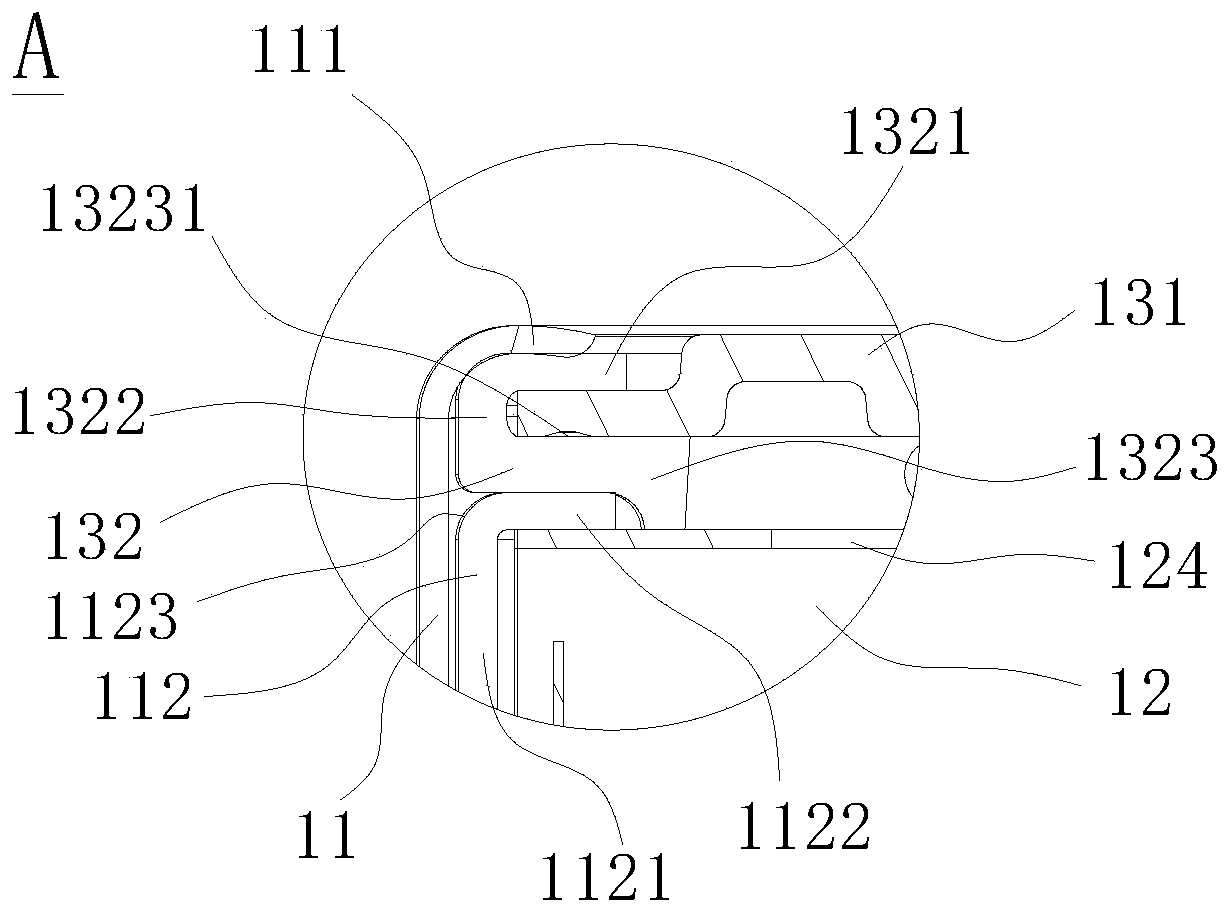

[0108] Compared with the first embodiment, the housing 31 of the battery structure of this embodiment has a built-in bracket 312 for supporting the cap 23, the second support part 3122 of the bracket 312 supports the cap 33, and one side of the second extension part 3121 is in contact with the housing. 31; and the other side of the second extension part 3121 is in contact with and insulated from the outer ring of the insulating plastic part 332. The structure of the bracket 312 in this embodiment is simplified, which reduces the space occupied by the bracket inside the casing; and the bracket 312 is sleeved around the cap 33, and the inside of the casing 31 can accommodate batteries with larger diameters, increasing the battery capacity.

[0109] Please refer to Figure 15 , Figure 16 and Figure 17 , Figure 15 It is a perspective view of the second cap structure of the second embodiment of the battery structure with a cap bracket of the present invention, Figure 16 It ...

no. 3 example

[0116] The battery structure in this embodiment includes a casing 51, an electric core 52 and a cap 53; wherein the casing 51 is used for installing components, and the casing 51 is a hollow cylindrical structure with one end open; the electric core 52 is arranged in the casing 51, It is used to provide electric energy; the cap 53 is arranged at the opening of one end of the housing 51 and is used to seal the opening of the housing 51 .

[0117] Wherein, the opening at one end of the housing 51 is provided with a sealing structure 511, and the sealing structure 511 is used to limit the position outside the cap 53; inside the housing 51, there is a bracket 512 for supporting the cap 53, and the bracket 512 is used to connect the cap 53 with the electric core. 52 spaced apart at one end.

[0118] combine Figure 21 , Figure 21 for Figure 20 The enlarged schematic diagram of the local structure. In this embodiment, the housing 51 includes a bottom plate 513 opposite to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com