A kind of modified light conversion material and its preparation method and application

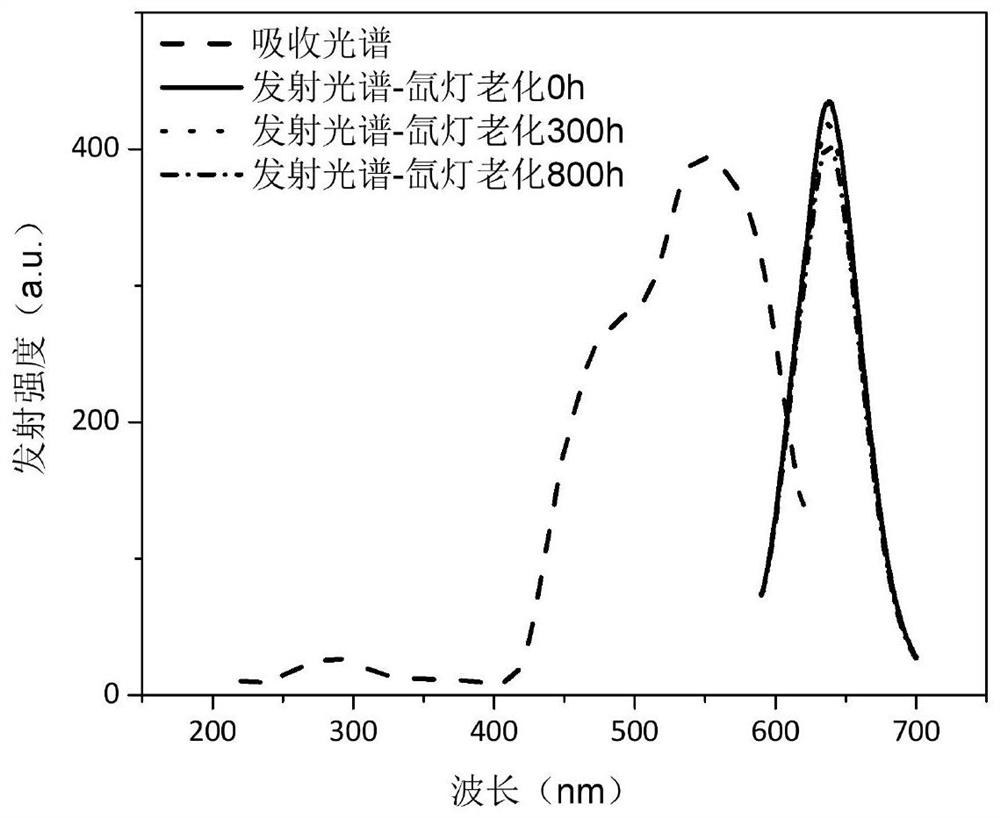

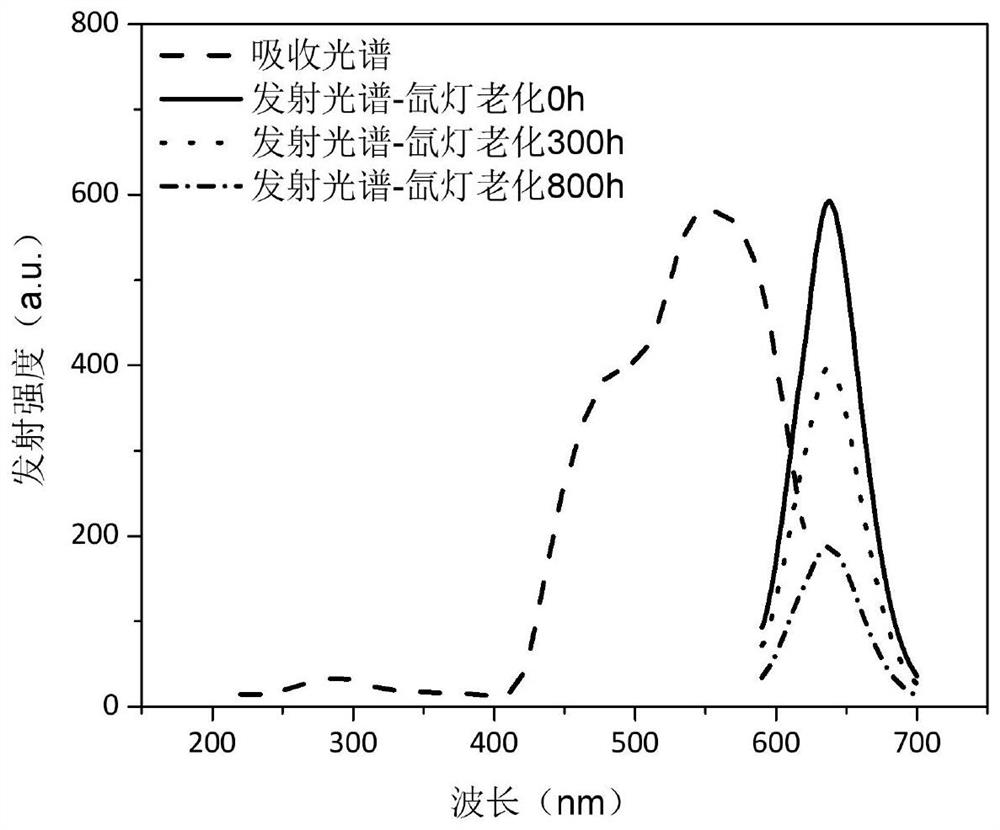

A modification and light conversion agent technology, applied in the field of materials, can solve the problems of water vapor, oxygen and ultraviolet instability, and achieve the effects of preventing contact, prolonging life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned modified light conversion material comprises the following steps:

[0035] (1) Fully mix the photostabilizer and the barrier material in the aqueous solution to form a micellar solution;

[0036] (2) Add light-converting material to the micellar solution, mix well, and cure at 15° C. to 80° C. to obtain light-converting material.

[0037] A third aspect of the present invention provides:

[0038] The application of the above modified light conversion material in a light conversion film, the modified light conversion material is the above modified light conversion material, or is obtained by the above preparation method.

Embodiment 1

[0041] Weigh 1 mass part of phenyl-o-hydroxybenzoate and 95 mass parts of PVDC in the aqueous solution and mix well to form a micellar solution; then add 4 mass parts of light-changing agent CaS:Eu, Mn to the micellar solution, After mixing, solidify at 25°C to obtain a modified light-converting material.

Embodiment 2

[0043] Weigh 10 parts by mass of phenyl-o-hydroxybenzoate and 50 parts by mass of PVDC in an aqueous solution and mix well to form a micellar solution; then add 40 parts by mass of light-changing agent CuInSSe to the micellar solution, and mix them in Curing at 50°C to obtain a modified light conversion material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com