Brick making production line and water adding method thereof

A production line and water pump technology, applied in separation methods, chemical instruments and methods, manufacturing tools, etc., can solve problems such as unstable physical properties, short aggregate water absorption time, poor quality of mixture, etc., achieve good environmental protection effect and prolong water absorption Time, the effect of long pre-wetting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

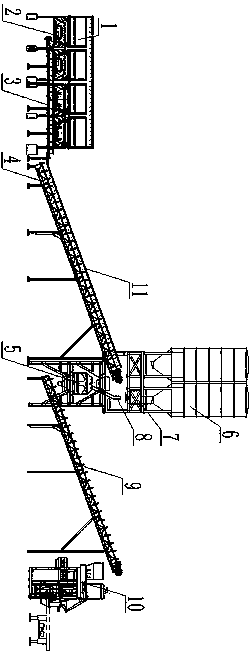

[0033] like figure 1 As shown, a brick production line includes a mounting frame, an aggregate bin 1, a powder bin 6, a mixer 5, a brick making machine 10, a water adding device 11 and a control system. The mounting frame here is the general name of all the brackets used , the aggregate bin 1, the mixer 5, the powder bin 6, the brick making machine 10, the water adding device 11 and the control system are all fixed on the installation frame, and the aggregate metering device 2 is arranged under the aggregate bin 1, and the Aggregate conveying device 3 is arranged below the discharge port of aggregate weighing device 2, and a first transfer conveying device 4 is arranged below said aggregate conveying device 3, and said first transfer conveying device 4 is connected to the feed port of mixer 5 , The aggregate bin 1 and the aggregate conveying device 3 can be arranged in a "line" or in an "L-shape".

[0034] A powder metering device 7 is arranged below the outlet of the powder ...

Embodiment 2

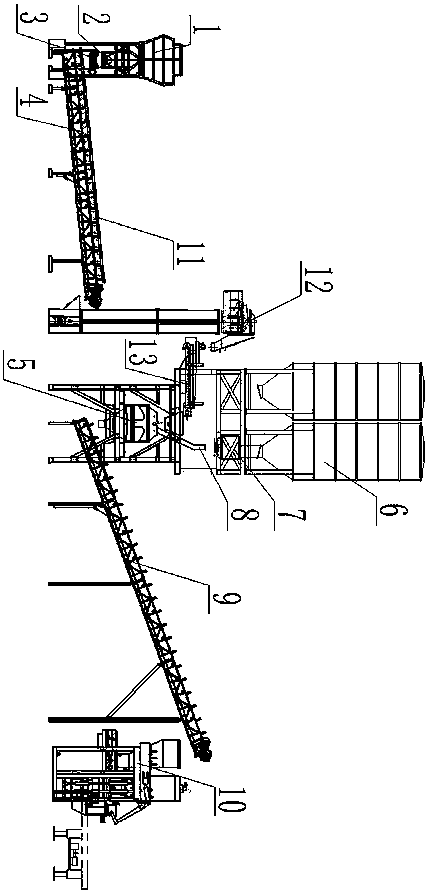

[0038] like figure 2 As shown, the difference from Example 1 is that a third transfer conveying device 12 is also provided between the first transfer conveying device 4 and the mixer 5, which can effectively reduce the height of the first transfer conveying device 4; The discharge end of the first transfer conveying device 4 is connected to the feed end of the third transfer conveying device 12, and an aggregate transfer belt conveyor 13 is arranged below the discharge end of the third transfer transfer device 12, and the aggregate transfer belt conveys Conveyor 13 transfers the aggregate conveyed by the bucket elevator to the mixer 5, the discharge end of the aggregate transfer belt conveyor 13 is connected to the feed port of the mixer 5, and the third transfer conveying device 12 adopts a bucket elevator , the third transfer conveying device 12 and the aggregate transfer belt conveyor 13 are both electrically connected to the control system.

[0039] like image 3 Shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com