Environment-friendly wood processing sawdust treatment equipment for forestry engineering

A technology for processing equipment and sawdust, applied to wood processing appliances, manufacturing tools, etc., can solve the problem of uncontrollable wood feeding speed, and achieve the effect of improving the degree of freedom of rotation, ensuring synchronization, and preventing collisions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

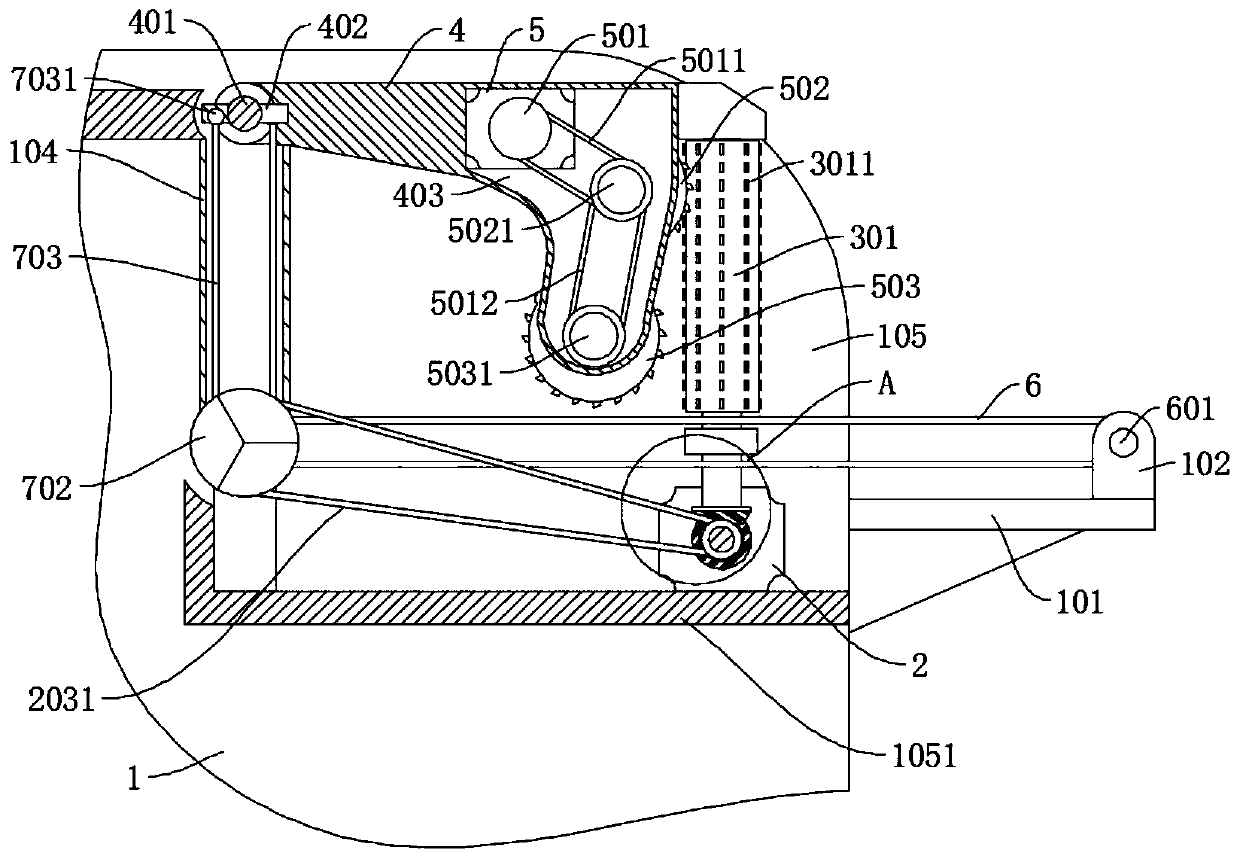

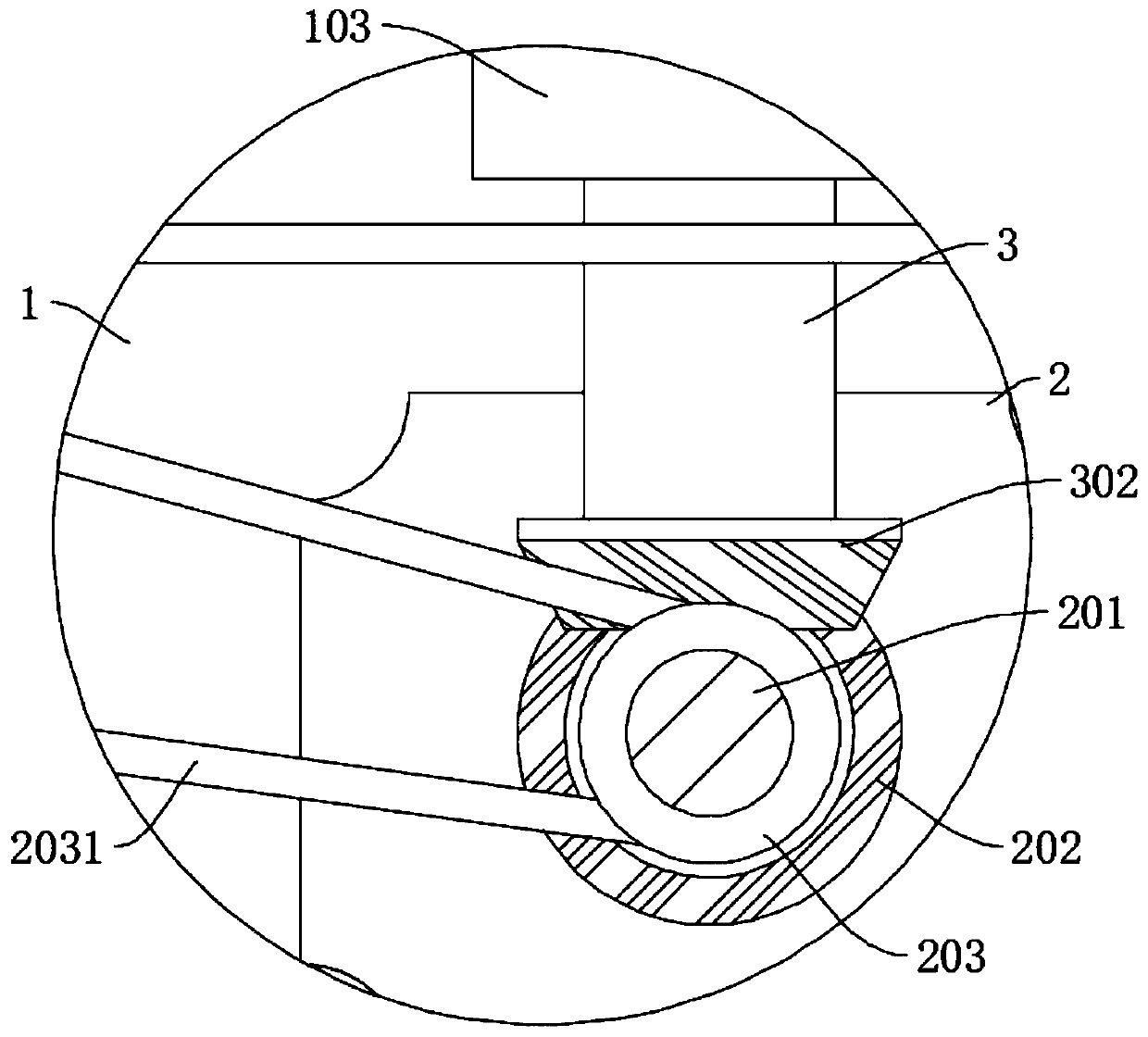

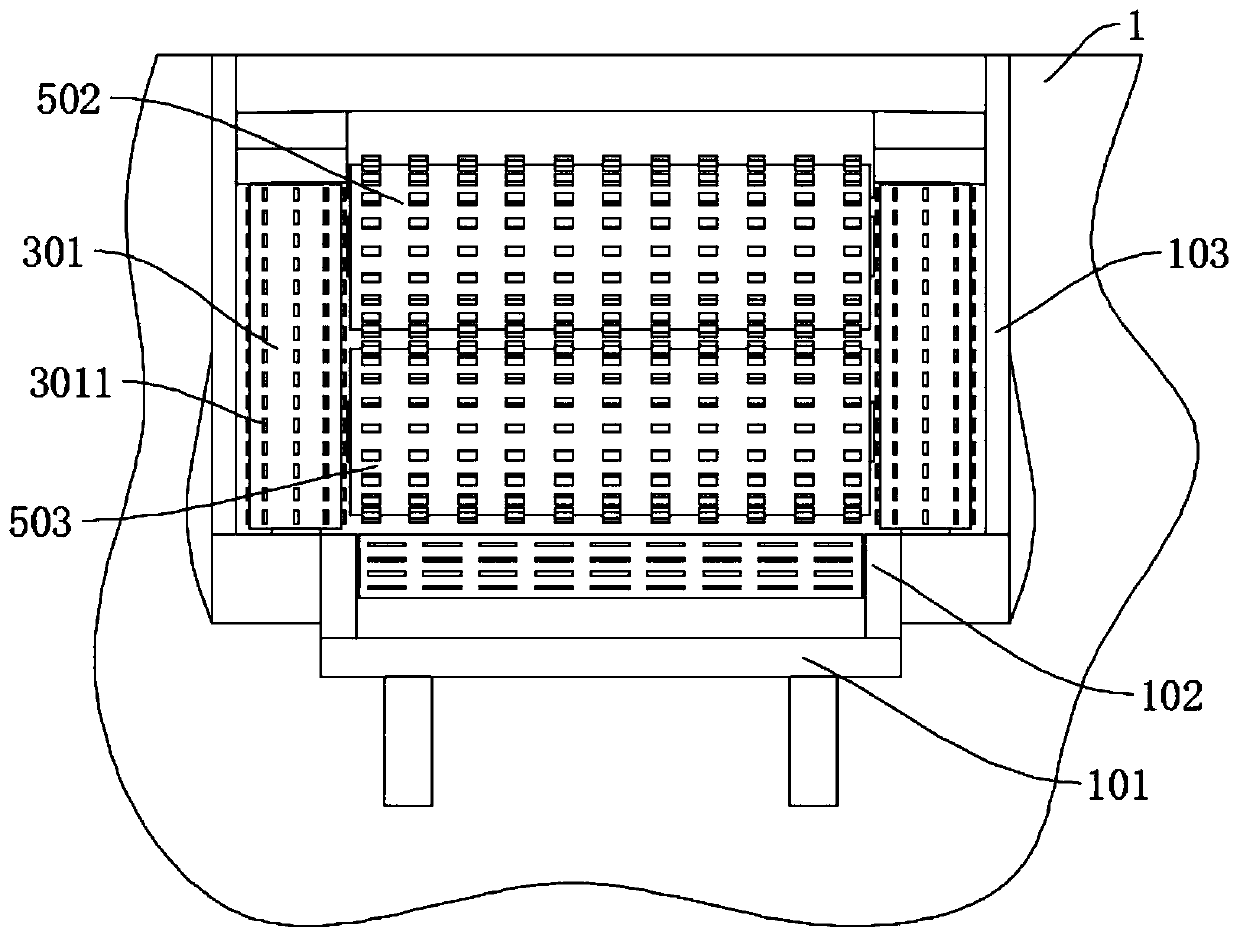

[0032] refer to figure 1 , image 3 , Figure 4 with Figure 5, an environment-friendly wood processing sawdust processing equipment for forestry engineering, comprising a sawdust machine body 1, a feed port 105 is provided on the sawdust machine body 1, the top of the feed port 105 is rotatably connected to a first rotating shaft 401, and the first rotating shaft 401 is fixed The L-shaped frame 4 is connected, and the L-shaped frame 4 is connected with the first feeding cylinder 502 and the second feeding cylinder 503 sequentially from top to bottom. The L-shaped frame 4 is provided with an installation cavity 403, the first feeding cylinder 502 and the second feeding cylinder 503 The rotating shaft where the feeding cylinder 503 is located extends into the installation cavity 403 and is respectively fixedly connected with a first pulley 5021 and a second pulley 5031. The first pulley 5021 is rotationally connected with the second pulley 5031 through a second belt 5012. Th...

Embodiment 2

[0034] refer to figure 1 , is basically the same as Embodiment 1, furthermore, the first driving part includes a first motor 5, the first motor 5 is fixedly connected to the top wall of the installation cavity 403, and the output end of the first motor 5 is fixedly connected to the first driving Wheel 501, the first driving wheel 501 is rotationally connected with the first pulley 5021 through the first belt 5011, and the first motor 5 drives the two sets of feeding cylinders through the belt, so as to prevent overloading and damage the first motor 5 while ensuring auxiliary feeding .

Embodiment 3

[0036] refer to figure 1 with Figure 4 , which is basically the same as that of Embodiment 1, furthermore, the feed port 105 is fixedly connected with a swing box 104, the connecting rod 703 is arranged in the swing box 104, and the first swing plate 402 and the second swing plate 701 are provided with The ball groove 7011, the two ends of the connecting rod 703 are fixedly connected with the ball 7031, the ball 7031 is rollingly connected in the ball groove 7011, and the connecting rod 703 moves up and down in the swing box 104, which can prevent the impact of wood and damage the swing accuracy, using a ball hinge The seat can increase the degree of freedom of rotation and ensure the synchronization of the first swing plate 402 and the second swing plate 701 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com