Breathable and environment-friendly mask supporting frame and sterilization mask applying same

A support frame and mask technology, which is applied in applications, clothing, clothing, etc., can solve the problems of hot air flow that cannot be eliminated in time, use comfort, reduced protective performance of masks, and poor face fitting comfort, etc., to achieve stable and firm structure. Simple, lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings. Any solution obtained by equivalent replacement and conventional reasoning of the technical features of the technical solution of the present invention falls within the protection scope of the present invention. The fixed connection, fixed arrangement, and fixed structure mentioned in this embodiment are all known technologies known to those skilled in the art, such as thermal fusion welding, integral injection molding, and the like.

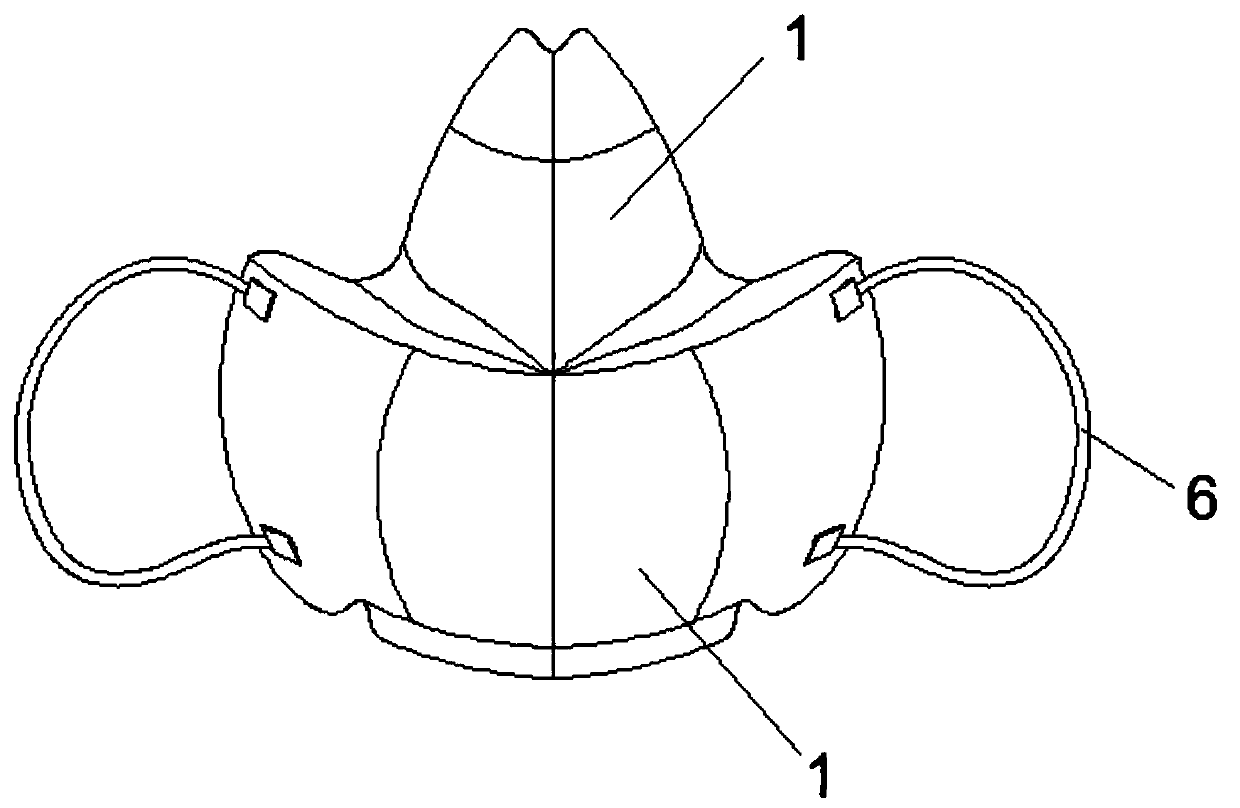

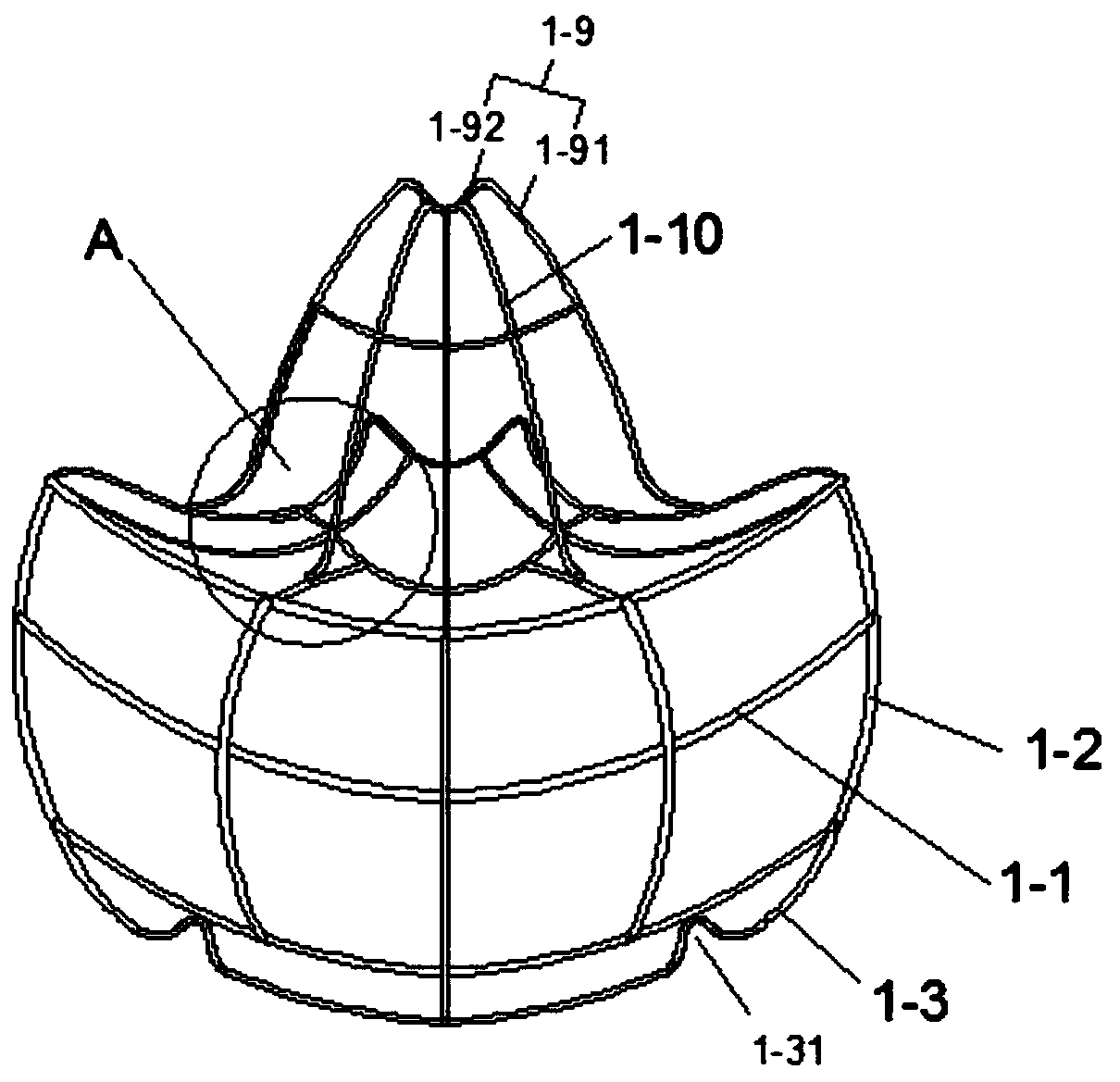

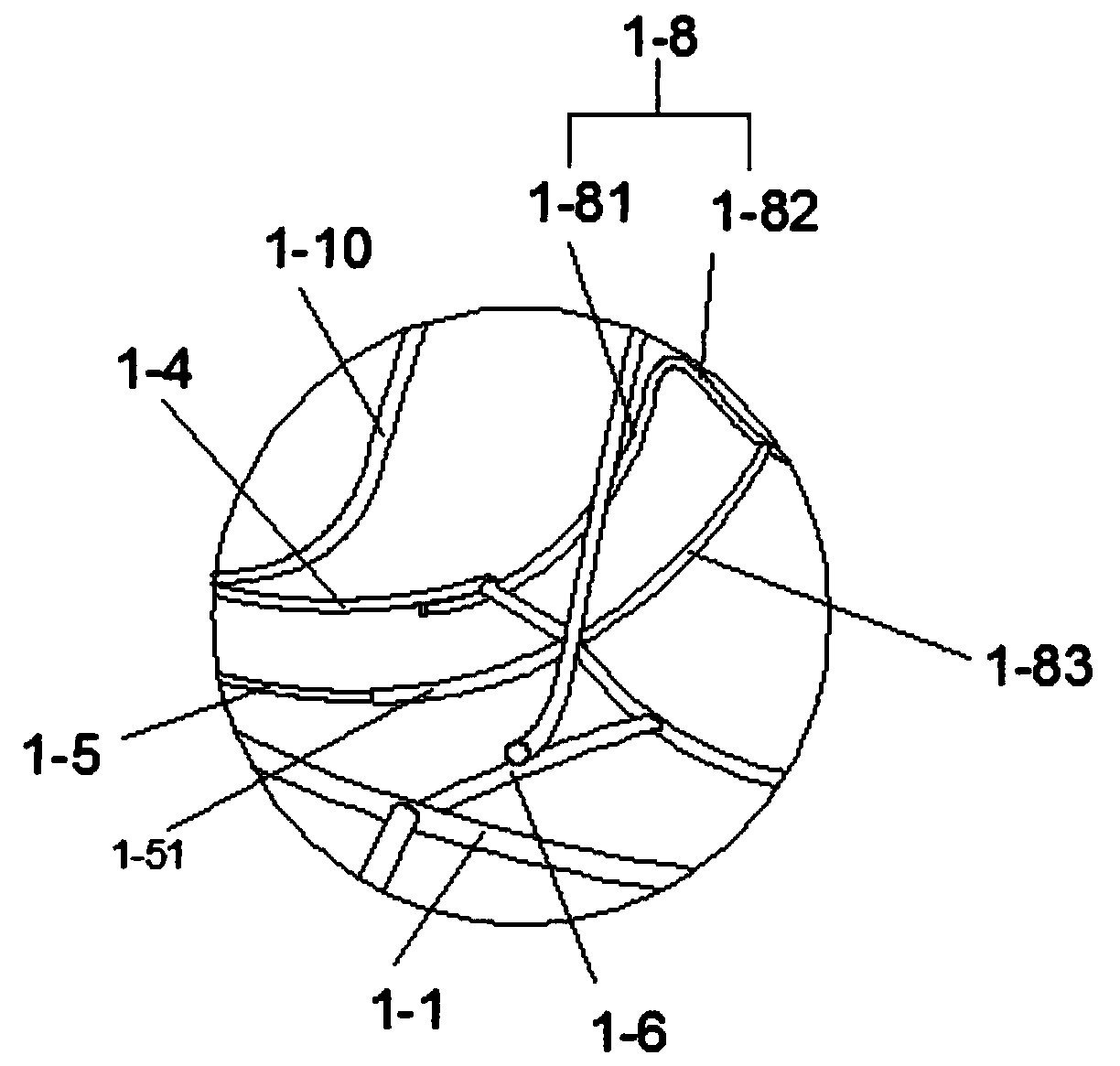

[0045] As can be seen in conjunction with the accompanying drawings, a breathable, environmentally friendly mask support frame, the support frame 1 includes a front face cross bar 1-1, a front face longitudinal bar 1-2, a front face bottom bar 1-3, a first ejector bar 1-4, The second push rod 1-5, the third push rod 1-6, the top connecting rod 1-7, the lower nose brid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com