Laser ultrasonic system and method for detecting elasticity modulus of material in non-contact mode

A technology for elastic modulus and material detection, applied in measurement devices, material analysis, material analysis by optical means, etc., can solve the measurement error of excitation line source and detection point, moving distance and measurement distance error, and the results are not very accurate and other problems to achieve the effect of ensuring accuracy, ensuring accuracy, and accurate elastic modulus of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

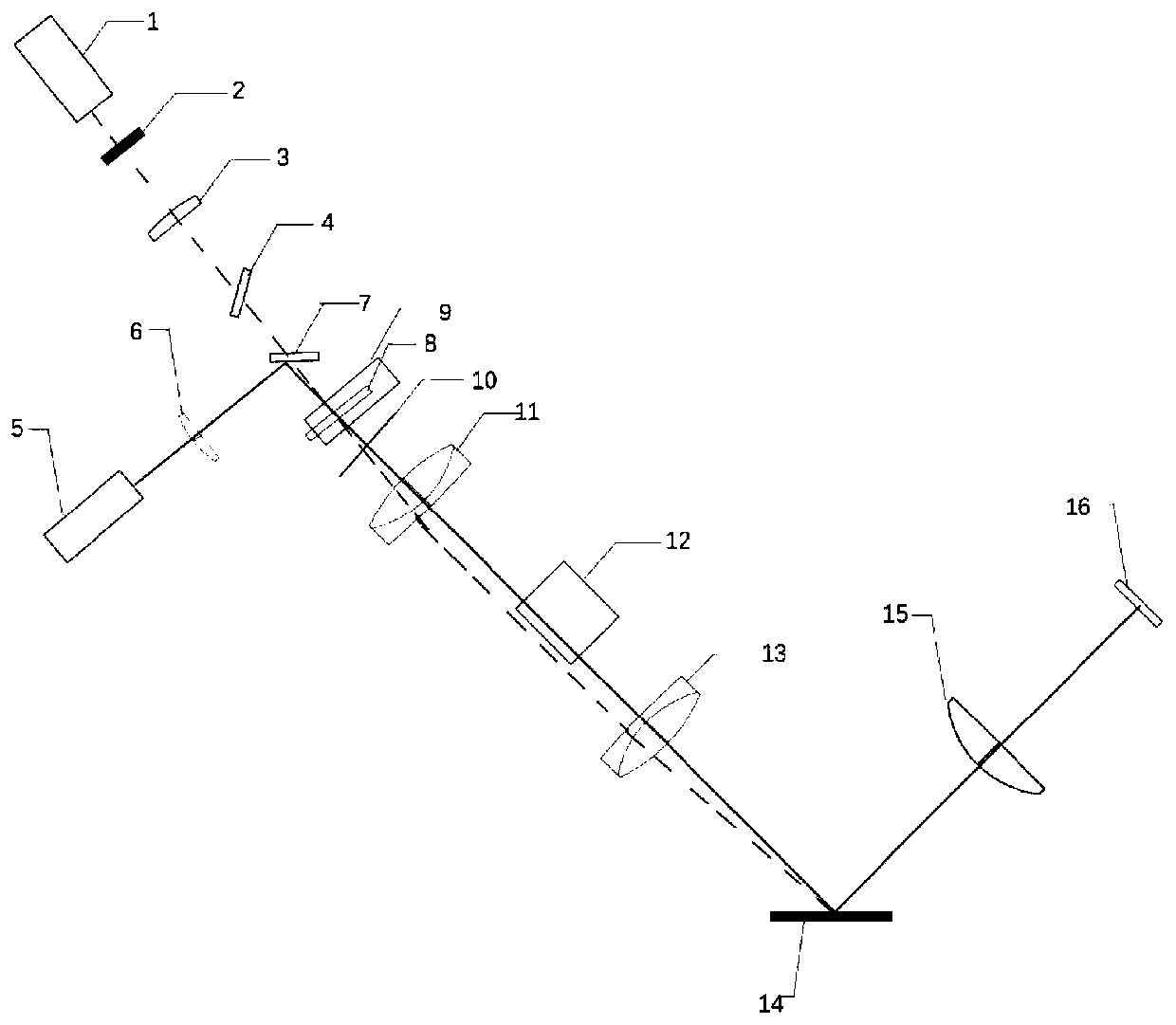

[0049] Such as figure 1 As shown, a laser ultrasonic system for non-contact detection of material elastic modulus, including excitation light emission module, detection light emission module, parallel plate 4, dichroic mirror 7, phase mask 8, phase mask electric adjustment Device 9, shutter 10, first achromatic lens 11, phase adjuster 12, second achromatic lens 13, moving sample stage and signal receiving module, and control phase mask electric regulator 9, so that the phase mask 8 Add or remove the optical path, and through the adjustment of the parallel plate, the system can be quickly and conveniently converted from the system for measuring surface acoustic wave signals to the system for measuring longitudinal wave and shear wave signals.

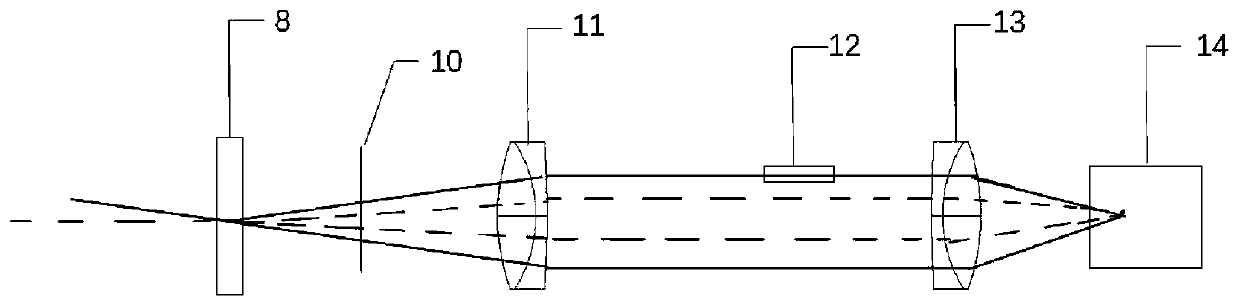

[0050] Such as figure 2 As shown, when the electric phase mask plate adjuster 9 is controlled so that the phase mask 8 is located in the optical path, the system at this time is a system for measuring surface acoustic wave signals. At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com