Ecological cyclic treatment and utilization process for residual vegetables

An ecological cycle, tail vegetable technology, applied in the application, animal feed, animal husbandry and other directions, can solve the problems of reducing ecological quality, not conducive to improving the ecological environment, increasing rural pollution, etc., reducing emissions, high treatment costs, and improving soil. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

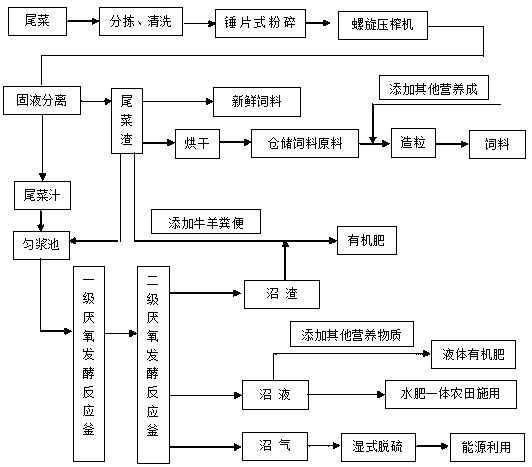

Image

Examples

Embodiment 1

[0042] (1) Collect a large number of tail vegetables produced in agriculture, and clean out foreign objects such as plastics, ironware, wood chips, soil clods, stones, paper pieces, mud roots, etc., as well as corrupted and deteriorated parts mixed in the tail vegetables;

[0043] (2) Put a part of the selected clean tail vegetables into the net chain bubble cleaning machine to wash away the soil inside;

[0044] (3) Then use a large hammer mill to crush the cleaned tail vegetables into powdery or pasty materials less than 3cm in order to enhance their fluidity;

[0045] (4) Feed the pulverized tail vegetable raw materials into a screw press for extrusion, so that the vegetable dregs and vegetable juice are fully separated, and at the same time further destroy the cellulose of the vegetables, and the tail vegetable dregs and tail vegetable juice obtained after pressing;

[0046] (5) The four treatments of tail vegetable dregs and tail vegetable juice are: fresh feed (first par...

Embodiment 2

[0054] An ecological recycling process for tail vegetables, characterized in that it comprises the following steps:

[0055] (1) Collect a large number of tail vegetables produced in agriculture, and clean out foreign objects such as plastics, ironware, wood chips, soil clods, stones, paper pieces, mud roots, etc., as well as corrupted and deteriorated parts mixed in the tail vegetables;

[0056] (2) Put a part of the selected clean tail vegetables into the net chain bubble cleaning machine to wash away the soil inside;

[0057] (3) Then use a large hammer mill to crush the cleaned tail vegetables into powdery or pasty materials less than 3cm in order to enhance their fluidity;

[0058] (4) Feed the pulverized tail vegetable raw materials into a screw press for extrusion, so that the vegetable dregs and vegetable juice are fully separated, and at the same time further destroy the cellulose of the vegetables, and the tail vegetable dregs and tail vegetable juice obtained after ...

Embodiment 3

[0071] An ecological recycling process for tail vegetables, characterized in that it comprises the following steps:

[0072] (1) Collect a large number of tail vegetables produced in agriculture, and clean out foreign objects such as plastics, ironware, wood chips, soil clods, stones, paper pieces, mud roots, etc., as well as corrupted and deteriorated parts mixed in the tail vegetables;

[0073] (2) Put a part of the selected clean tail vegetables into the net chain bubble cleaning machine to wash away the soil inside;

[0074] (3) Then use a large hammer mill to crush the cleaned tail vegetables into powdery or pasty materials less than 3cm in order to enhance their fluidity;

[0075] (4) Feed the pulverized tail vegetable raw materials into a screw press for extrusion, so that the vegetable dregs and vegetable juice are fully separated, and at the same time further destroy the cellulose of the vegetables, and the tail vegetable dregs and tail vegetable juice obtained after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com