Method for culturing microalgae by using benzoic acid

A benzoic acid and microalgae technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of limiting the growth of microalgae cells, reducing the overall biological yield, etc., so as to improve the composition of oil and improve the yield. , Improve the effect of oil conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

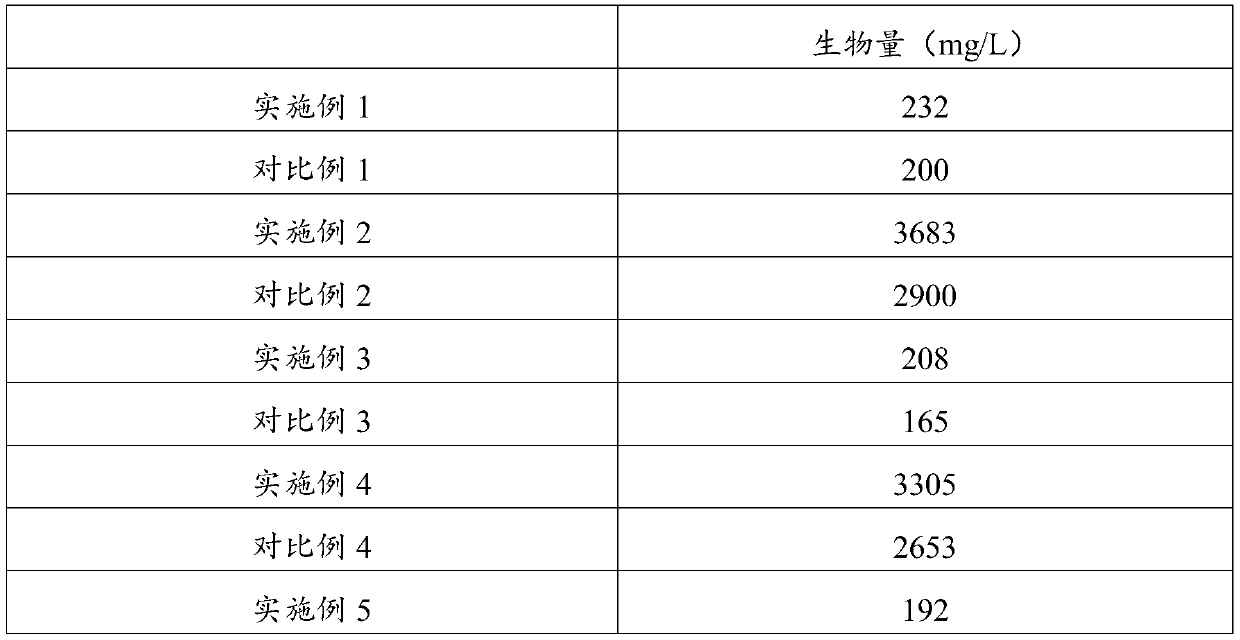

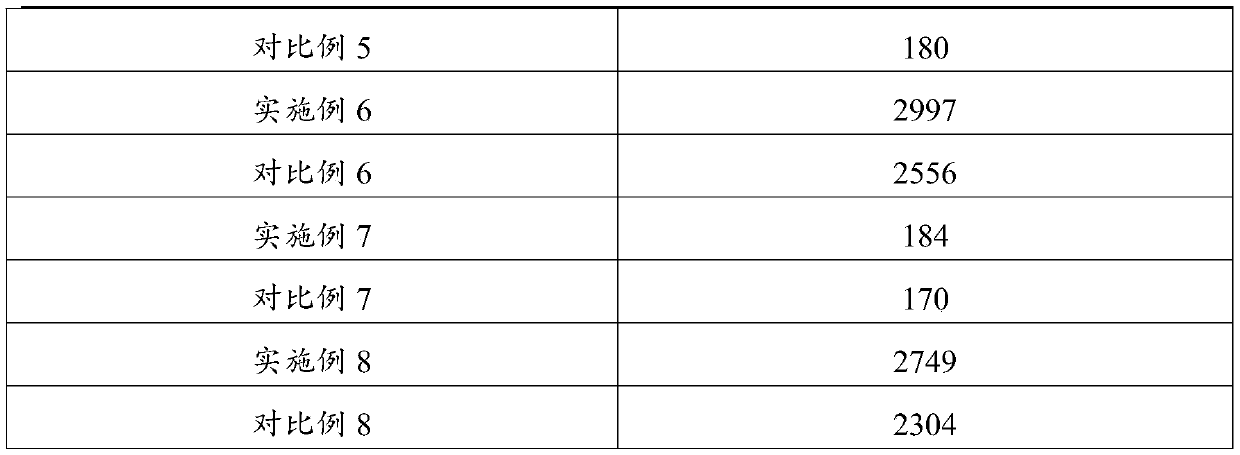

Examples

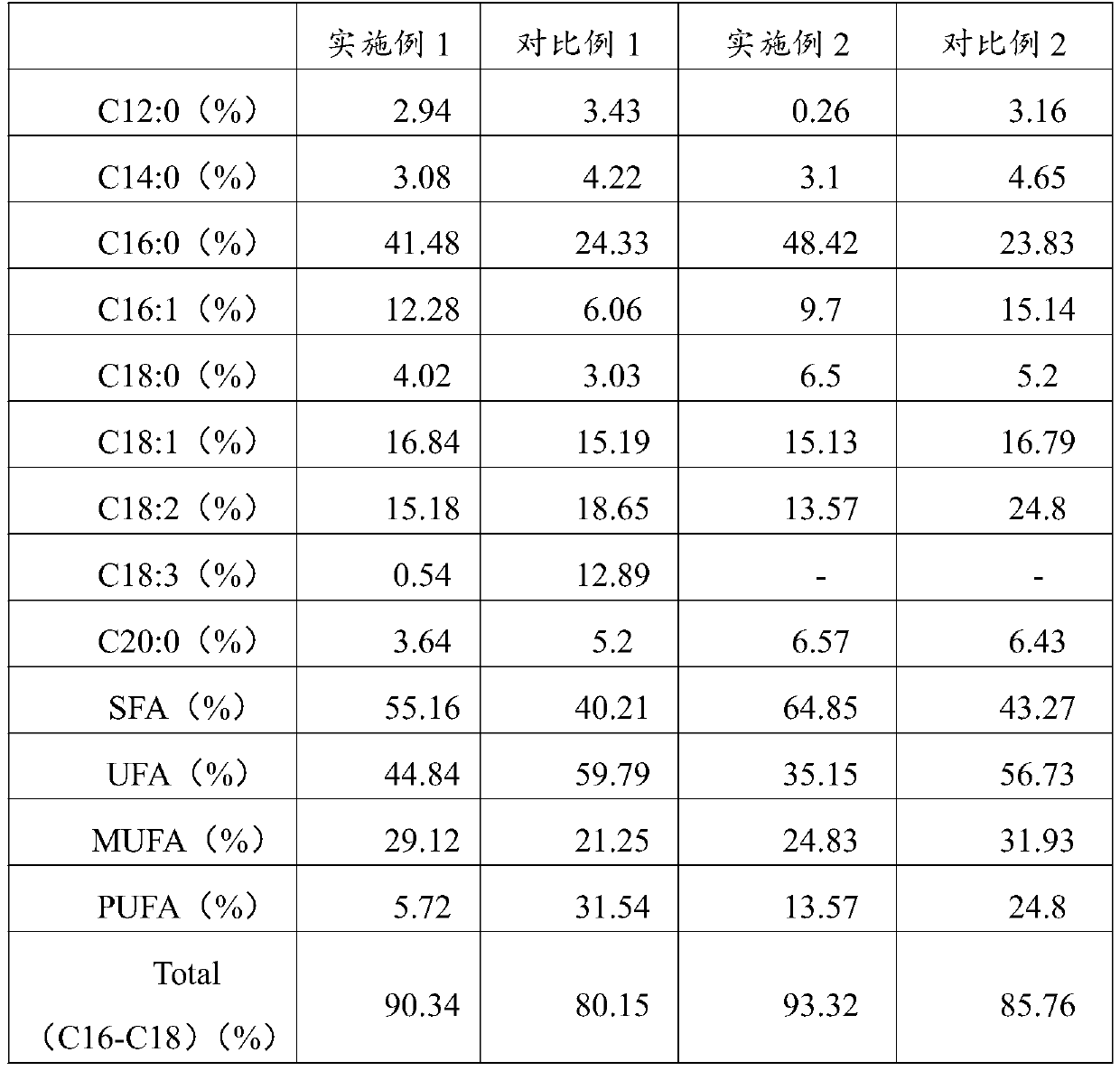

Embodiment 1

[0024] autotrophic model

[0025] Inoculate 10% chlorella into the basic BG11 medium for cultivation, and after 12 days of cultivation, obtain chlorella at the initial stage of the growth adjustment period;

[0026] The chlorella at the initial stage of the growth adjustment period was inoculated in the medium that added benzoic acid (BA) to the basic BG11 medium, wherein the concentration of benzoic acid was 500 μg / L. After mixing, the chlorella cells were mixed by 10 % volume fraction was inoculated into the above-mentioned BA-containing medium, and the initial concentration was adjusted to OD680 of 0.5. After mixing, it was placed in a photoreactor with a temperature of 20°C, a rotation speed of 150rpm, a light intensity of 4000Lux, and a light / dark ratio It is 16h / 8h, and it will be harvested on the 12th day after multiplication.

Embodiment 2

[0028] In the glucose-containing medium, inoculate 10% chlorella for cultivation, and after culturing for 8 days, obtain chlorella at the initial stage of the growth adjustment period, wherein the glucose-containing medium contains 10 g of glucose per liter of BG11 medium;

[0029] Inoculate the chlorella at the initial stage of the growth adjustment period into the medium containing benzoic acid (BA) in the basic BG11 medium containing glucose, wherein the concentration of benzoic acid is 500 μg / L. After mixing, the chlorella Cells were inoculated into the above-mentioned BA-containing medium at a volume fraction of 10%, and the initial concentration was adjusted to OD680 of 0.5. After mixing, they were placed in a photoreactor, the light mode was turned off, and the whole was covered with tinfoil. The temperature is room temperature (about 20° C.), the rotation speed is 150 rpm, and the harvest is performed on the 8th day after multiplication.

Embodiment 3

[0031] The condition parameters are the same as in Example 1, except that in this example, 10% Scenedesmus will be inoculated for cultivation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com