Material conveying equipment and material conveying method

A material conveying and equipment technology, applied in the field of material conveying equipment, can solve problems such as easy tilting of materials to be conveyed, manual participation, and influence on the smoothness of conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

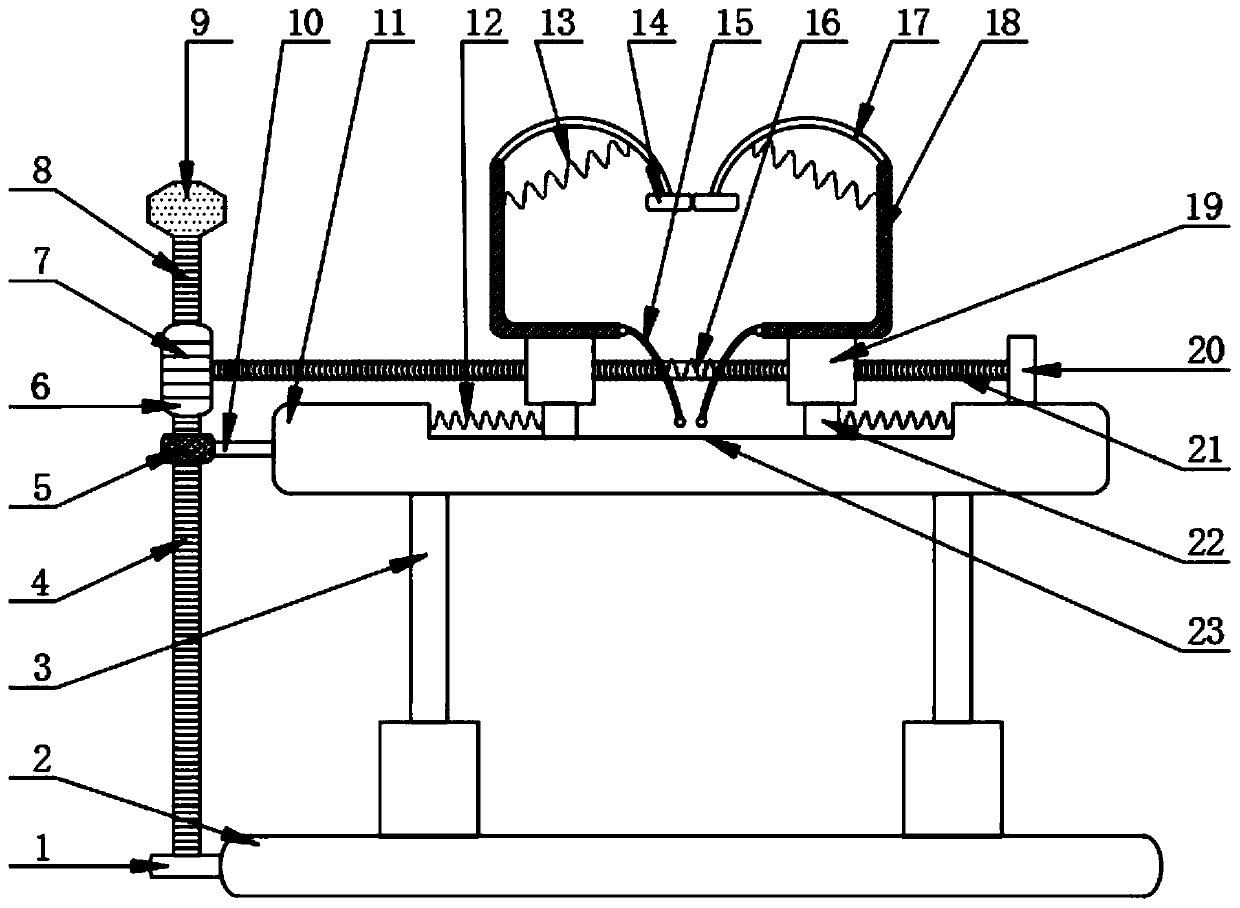

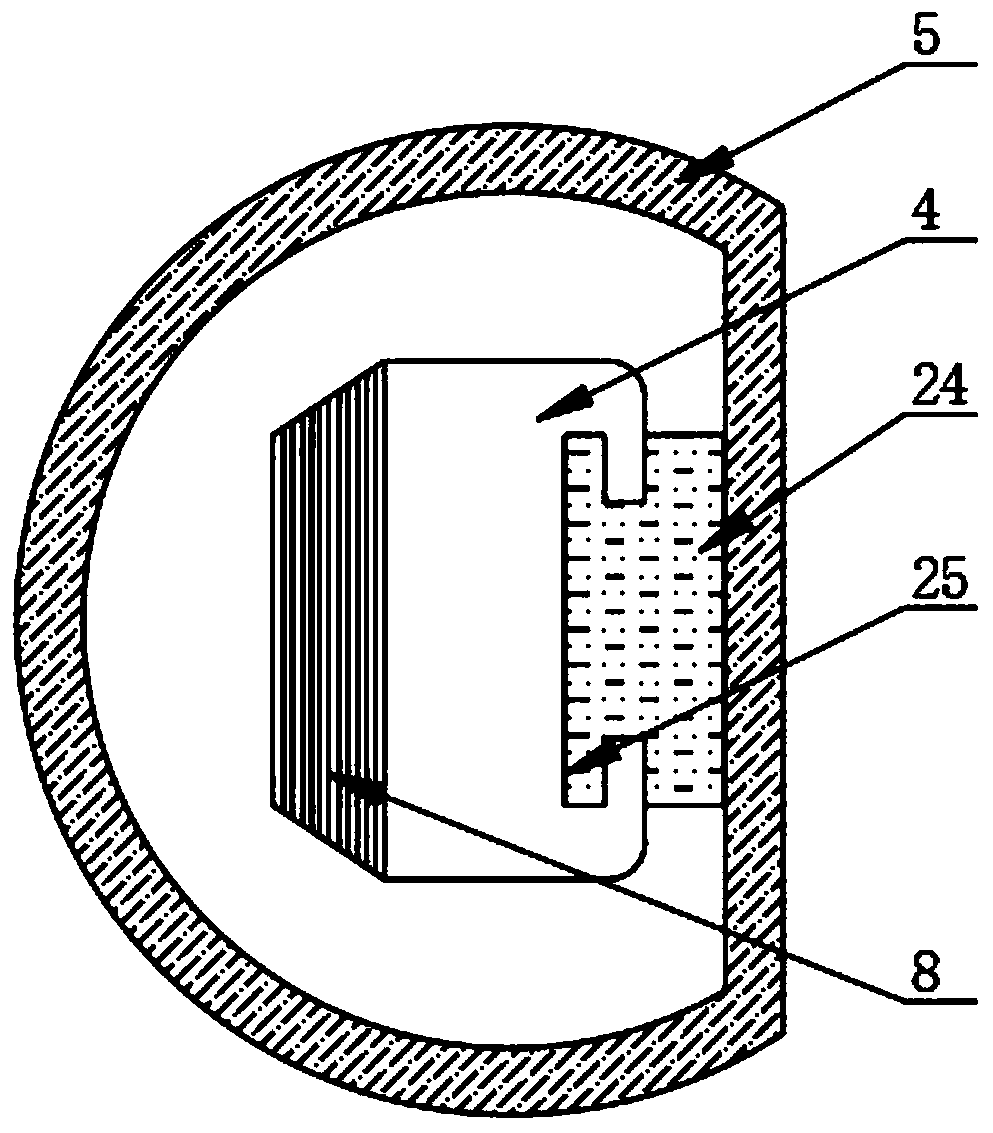

[0027] Such as Figure 1-2 As shown, the conveying equipment includes support block 1, bottom plate 2, electric push rod 3, column 4, collar 5, knob 6, first tooth groove 7, second tooth groove 8, wear-resistant rubber block 9, connecting rod 10. Fixed plate 11, first telescopic spring 12, second telescopic spring 13, pad 14, first elastic rod 15, third telescopic spring 16, second elastic rod 17, L-shaped splint 18, threaded sleeve 19, Block 20, threaded rod 21, slide block 22, chute 23, block 24 and draw-in groove 25, the top of bottom plate 2 is evenly provided with electric push rod 3, and the top of electric push rod 3 is fixed with fixed plate 11 by bolt;

[0028]The top center of the fixed plate 11 is provided with a chute 23, the inside of the chute 23 is correspondingly equipped with a slide block 22, and a second side wall is fixed by spot welding between one side of the slide block 22 and the adjacent side inner wall of the chute 23. A telescopic spring 12, the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com