Check fixture

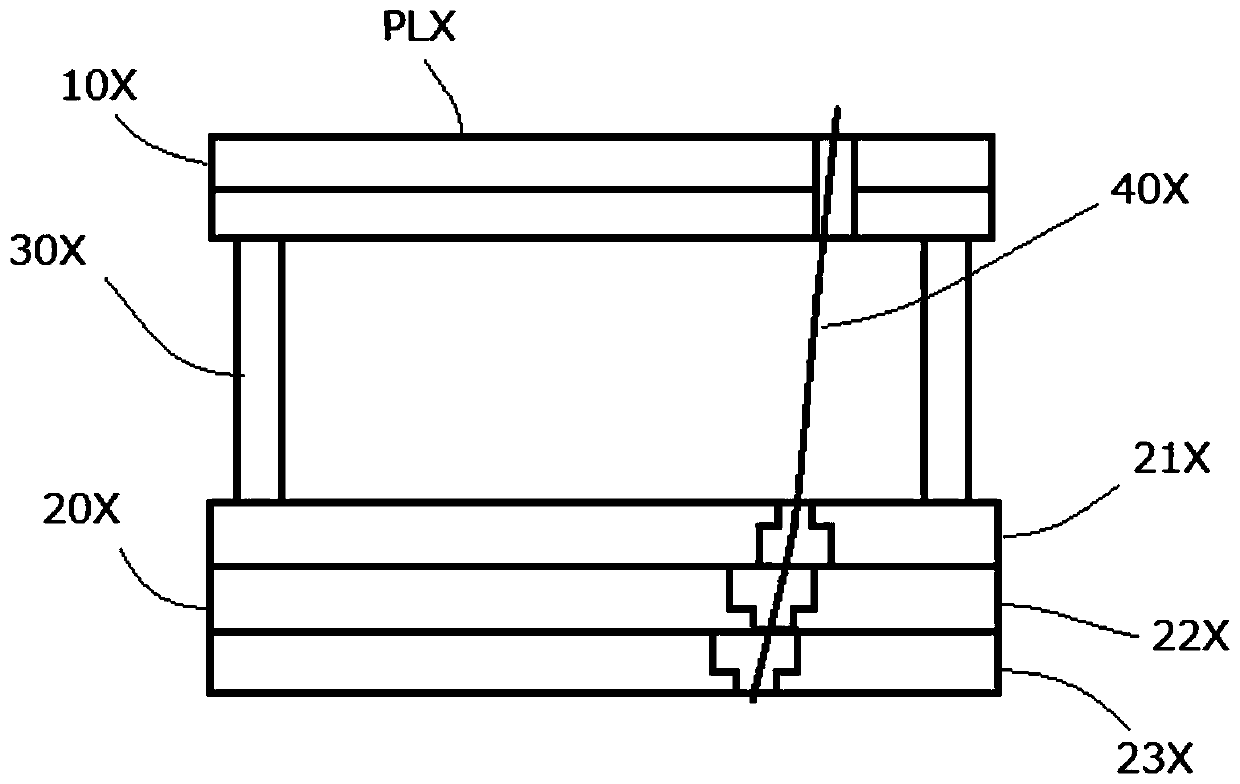

A fixture and side support technology, which is applied in the direction of instruments, measuring devices, electronic circuit testing, etc., can solve the problems that the probe 40X is easy to wear and the service life of the probe 40X is shortened, so as to avoid wear, prolong the service life, reduce the wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

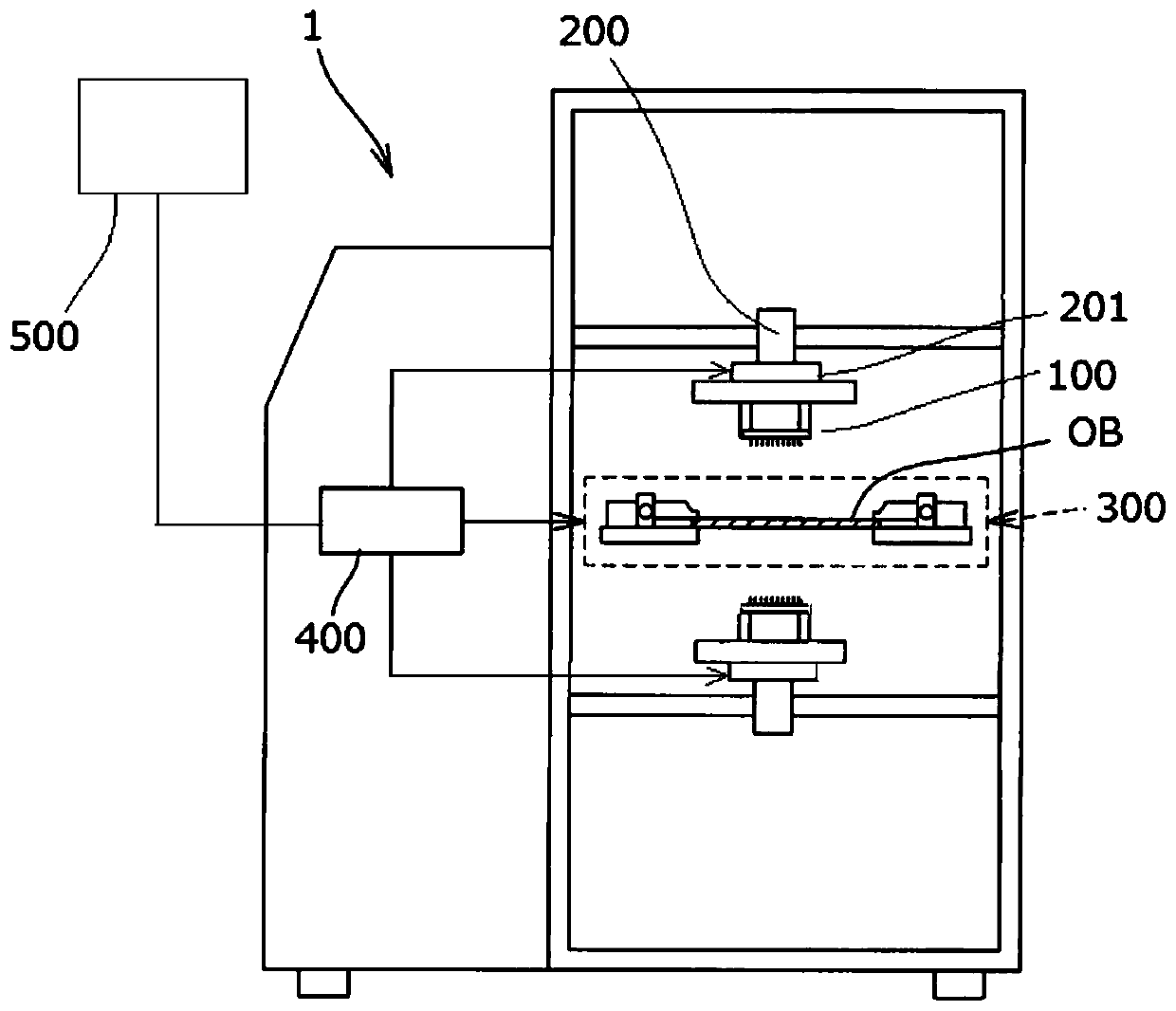

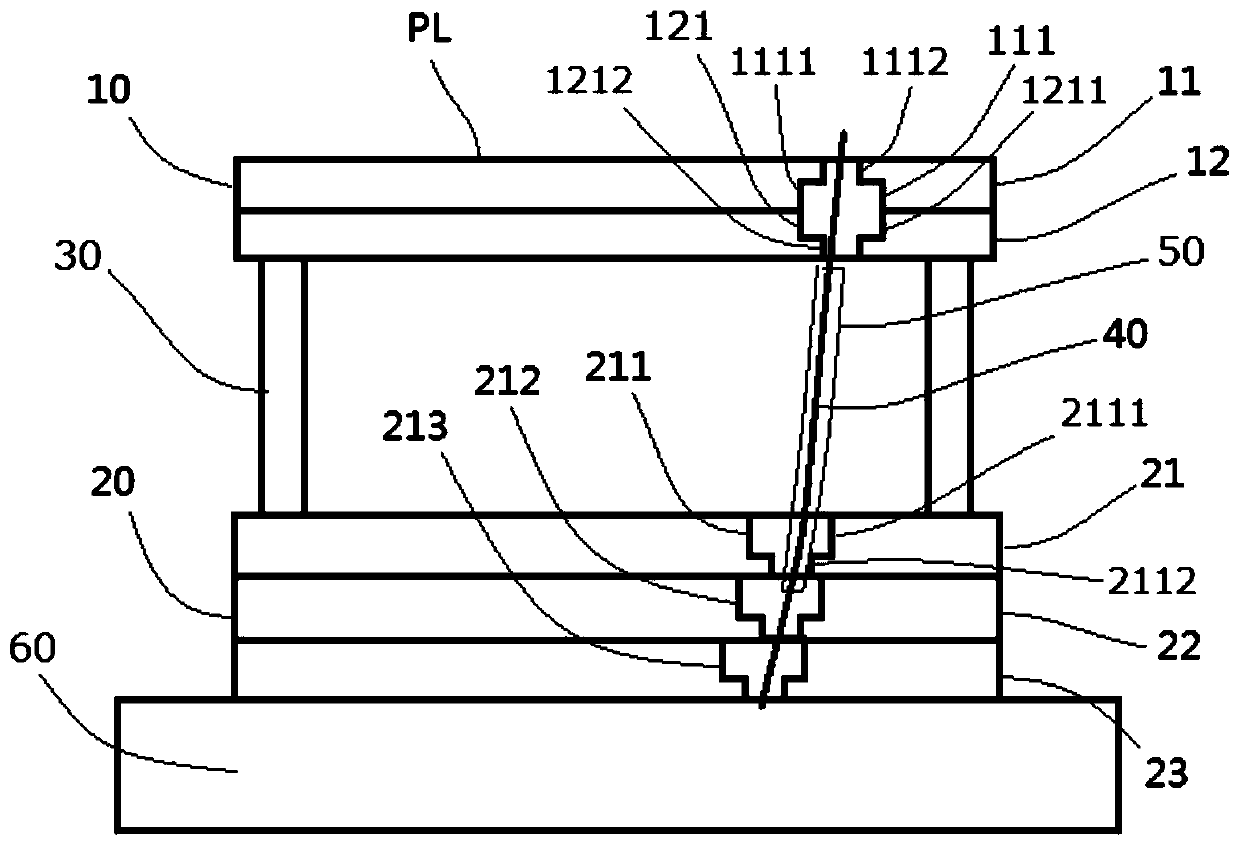

[0055] Below, combine figure 1 and figure 2 , an inspection device having an inspection jig according to an embodiment of the present invention is described, wherein, figure 1 is an overall configuration diagram schematically showing an inspection device having an inspection jig according to an embodiment of the present invention, figure 2 is a diagram schematically showing an inspection jig according to an embodiment of the present invention, and shows figure 1 Check the upper inspection jig in the middle.

[0056] Such as figure 1 As shown, the inspection device 1 includes: an inspection fixture 100; a moving mechanism 200, the moving mechanism 200 is used to move the inspection fixture 100, and the moving mechanism 200 has a fixture installation part 201, and the fixture installation part 201 is used to install the inspection fixture 100 (Specifically, it supports the following electrode mounting part 60 of the inspection jig 100); a transport mechanism (not shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com