Automatic feeding equipment for die stamping

A technology of feeding equipment and molds, which is applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of large coil material quality, time-consuming and labor-consuming, laborious and troublesome handling, and improve installation efficiency and handling efficiency , to avoid troublesome and laborious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

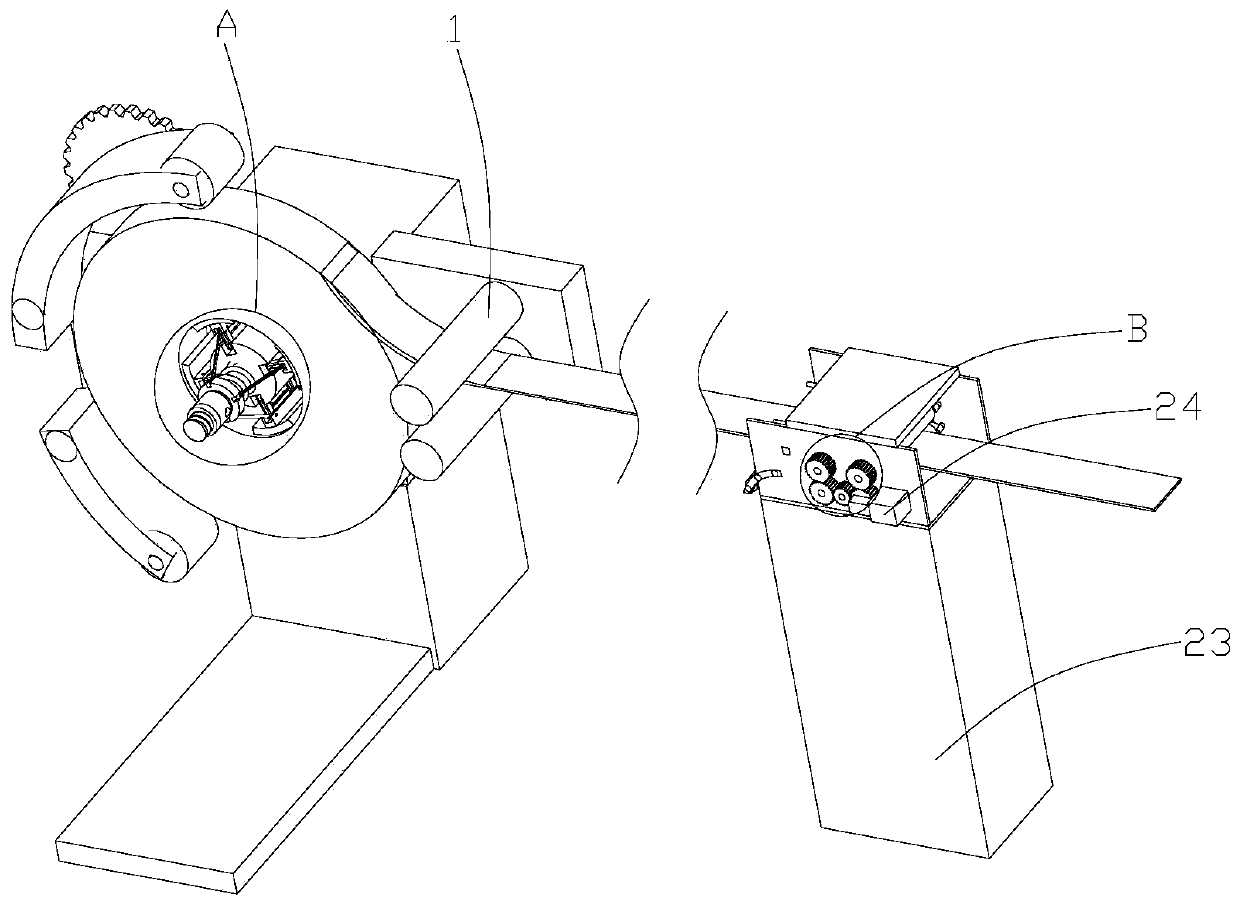

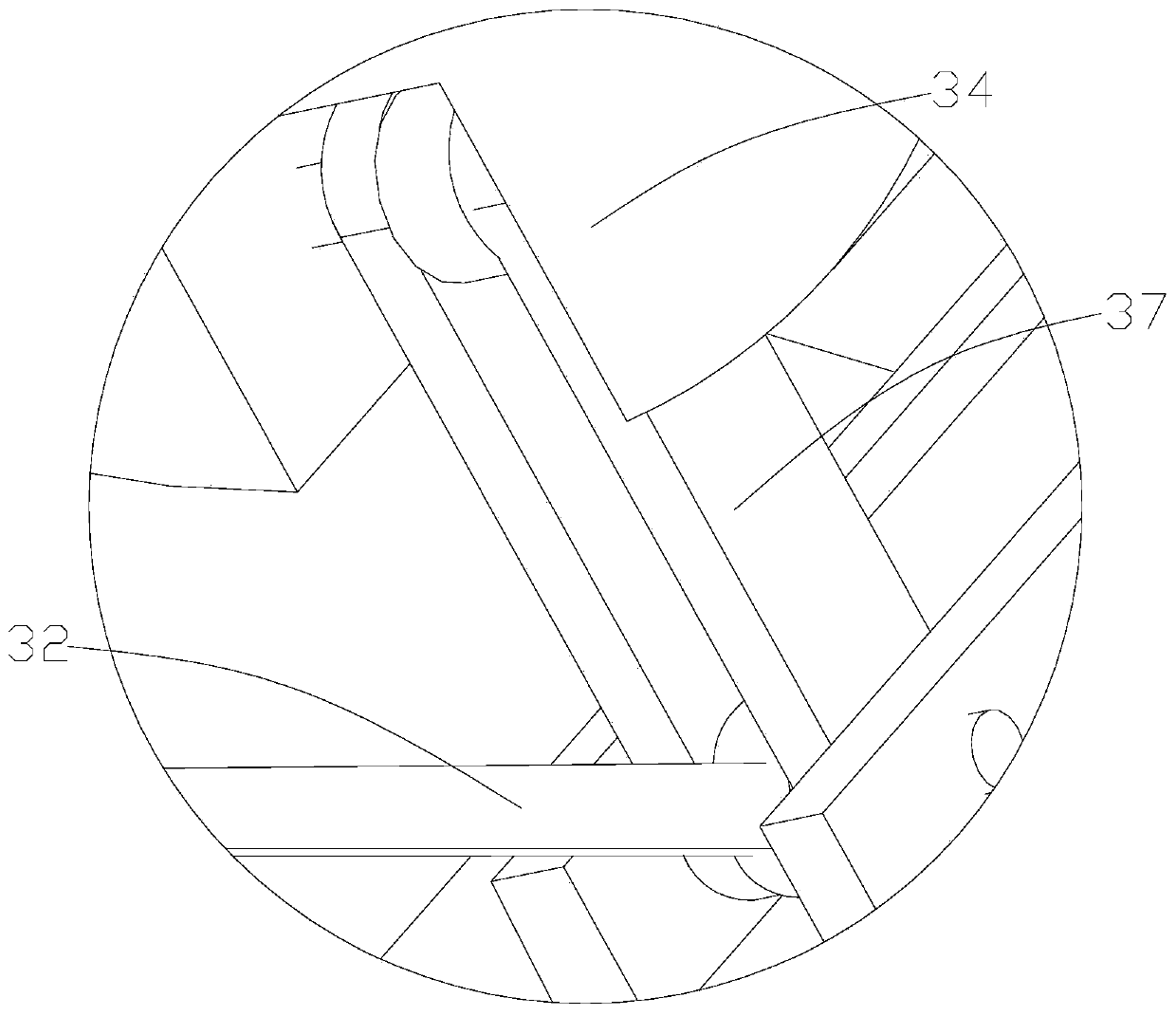

[0025] Such as Figure 1-12 As shown, a kind of automatic feeding equipment for mold stamping, including a fastening mechanism for conveying the coil material to be stamped, a guide roller group 1 for guiding and conveying one end of the coil material and for preventing The anti-throwing mechanism that the coil material is thrown out from the fixing mechanism after the coil material is about to be conveyed also includes a feeding mechanism for clamping and feeding the coil material. The first pinch roller 21 and the second pinch roller 22, the adjusting device for automatically adjusting the spacing of coil materials of different specifications, and the support base 23 for supporting the first pinch roller 21 and the second pinch roller 22 , through the setting of the above structure, the efficient and stable delivery of the coil material can be effectively realized, so that when the coil material is stamped, the coil material can be fixedly transported, and the shaking of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com