Low-sodium compound seasoning and preparation method thereof

A compound seasoning and sodium chloride technology, which is applied in food ingredients as taste improvers, functions of food ingredients, and food forming, etc., can solve the problems of high sodium content and inability to provide nutrition, so as to reduce sodium content and satisfy The effect of intake

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

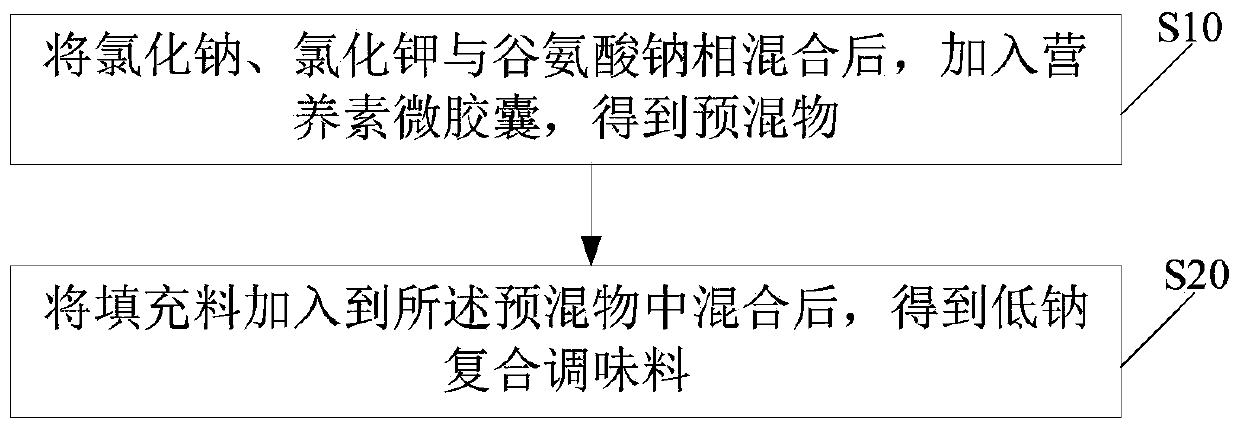

[0052] In the present invention, the preparation method of the low-sodium compound seasoning also includes the steps of:

[0053] S30. After the low-sodium compound seasoning is made into a wet powder by spraying or adding a dextrin agent, it is granulated by a granulator, and after drying at a high temperature to ensure stable quality, the low-sodium nutritional compound seasoning granules are obtained.

[0054] Specifically, in order to facilitate storage, transportation and use, the low-sodium compound seasoning can be prepared into granules, and the powdered low-sodium compound seasoning is made into a wet powder by adding dextrin, and then granulated by a granulator, and the finished product is dried Packaging, the packaging specification can be 10 bags per bag, 5 grams per bag. The specific packing specification and packing form are not limited here.

Embodiment 1

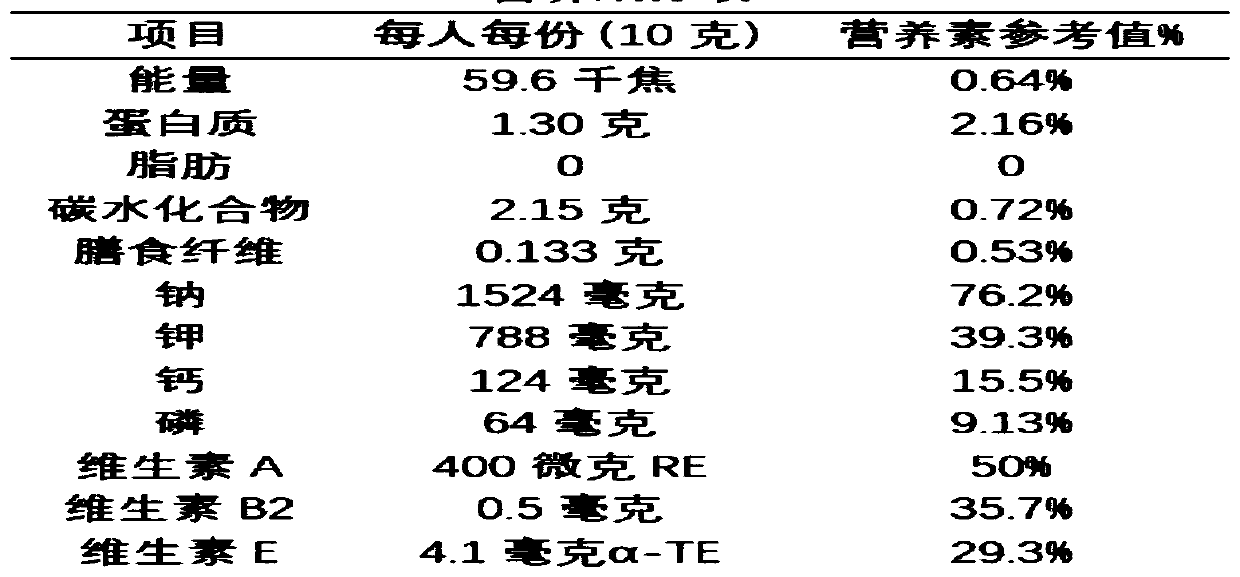

[0057] Take by weighing 70 parts of sodium chloride, 30 parts of potassium chloride, and 20 parts of sodium glutamate and put into a container and stir evenly. Add 14 parts of nutrient microcapsules in the container, wherein β-carotene microcapsules account for 0.25%, riboflavin microcapsules account for 0.15%, vitamin E acetate microcapsules account for 1.38%, and tricalcium phosphate microcapsules account for 98.22%. After stirring evenly, add 35 parts of maltodextrin, 15 parts of soybean protein isolate, and 10 parts of cornstarch as filling and put into the container and stir and mix evenly. Use spray or add dextrin to make wet powder, use granulator to make wet powder into white to light yellow granules and dry them for finished product packaging.

Embodiment 2

[0059] Weigh 78 parts of sodium chloride, 33 parts of potassium chloride, 22 parts of sodium glutamate, and 2 parts of disodium 5' taste nucleoside, put them into a container and stir evenly. Add 14.5 parts of nutrient microcapsules in the container, wherein β-carotene microcapsules account for 0.25%, riboflavin microcapsules account for 0.15%, vitamin E acetate microcapsules account for 1.38%, and tricalcium phosphate microcapsules account for 98.22%. After stirring evenly, add 35.5 parts of maltodextrin, 24.5 parts of soybean protein isolate, and 12.2 parts of cornstarch as filling and put them into the container and stir and mix them evenly. Wet powder is made by spraying or adding dextrin, and the wet powder is made into white to light yellow granules by a granulator, and the finished product is packaged after drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com