Quick reconstruction method for three-dimensional model of water turbine blade

A three-dimensional model and water turbine technology, applied in the field of water turbine blades, can solve the problems of high maintenance cost, large volume, complex shape, etc., and achieve the effects of ensuring reliability and stability, reducing costs, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

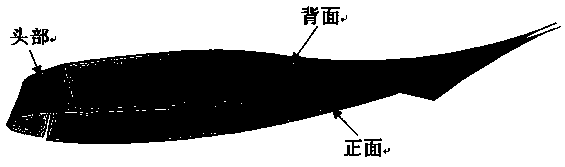

[0026] Embodiment 1: as figure 1 As shown, a method for fast reconstruction of a three-dimensional model of a water turbine blade is characterized in that the method includes the following steps: 1) Acquisition of blade point data; 2) Fitting of the blade profile in the three-dimensional modeling software NX; reconstruction.

[0027] Among them, such as figure 1 As shown, in the step 1), the blade surface point data is obtained by directly measuring the blade with a three-dimensional coordinate measuring machine, and then it is subjected to fine processing of noise point removal, point coordinate calibration, and point integrity detection.

[0028] Since the blade surface of the water turbine is mostly a complex free-form surface, the blade is large in size and heavy in weight, so when the three-coordinate measuring machine measures the data of each surface point of the blade, attention should be paid to the placement of the blade on the three-coordinate measuring platform, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com