Detection system and detection method for grouting quality of fabricated structure

A detection system and detection method technology, which are applied to measurement devices, processing response signals of detection, and analysis of solids using sonic/ultrasonic/infrasonic waves, etc. problems, to achieve the effect of light weight, accurate results, improved detection accuracy and detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

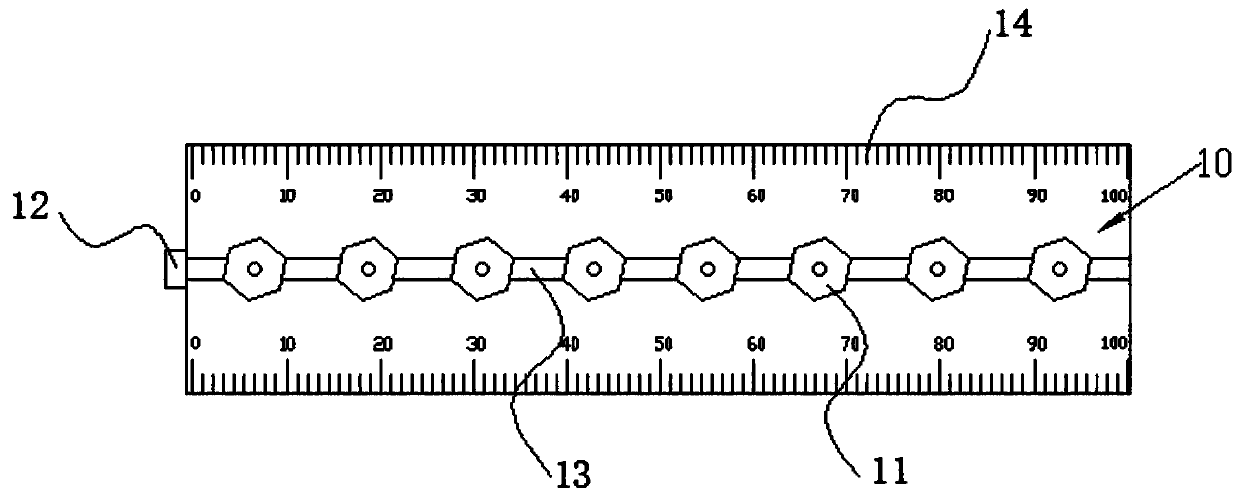

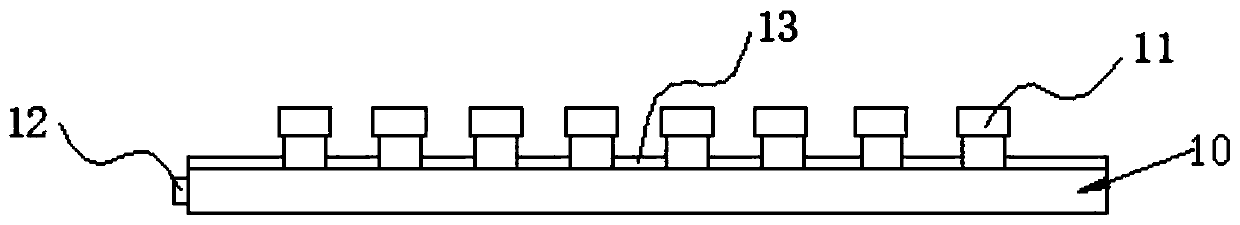

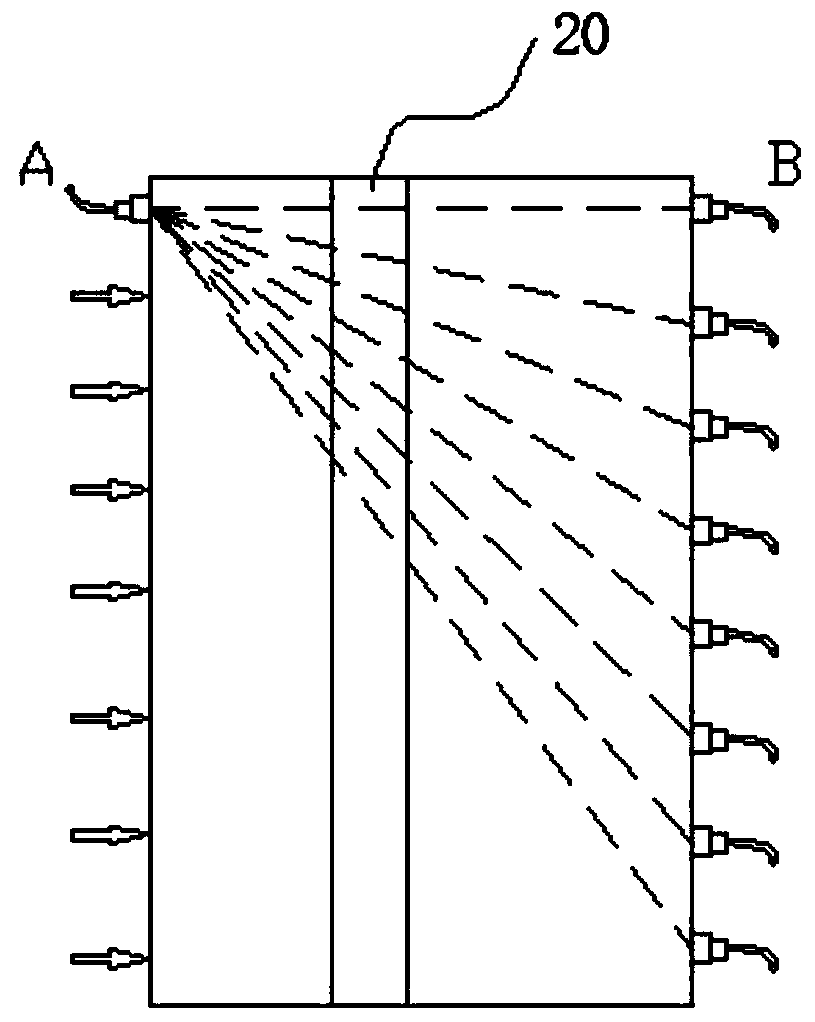

[0043] like Figure 1-Figure 3 As shown, a detection system for grouting quality of prefabricated structures, the detection system includes a signal receiving device 10, the signal receiving device 10 is provided with a scale 14, the scale 14 is located on the edge of the signal receiving device 10, used Mark the position of the test grouting sleeve 20 and the position coordinates of the piezoelectric sensor 11 on the spot, and the signal receiving device 10 is equidistantly provided with a plurality of piezoelectric sensors 11 for receiving signals along the length direction of the scale 14 , the signal receiving device 10 is also provided with a BNC signal interface 12 connected to the piezoelectric sensor 11 .

[0044] The working principle of the above-mentioned technical scheme is as follows:

[0045] By manual pressing, the signal receiving device 10 is closely attached to the concrete surface where the sleeve 20 to be tested is located, and an effective signal with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com