Magnetoacoustic emission detection method for fatigue damage of ferromagnetic metal component

A technology of acoustic emission detection and metal components, which is applied in the field of non-destructive testing of material damage, can solve the problems of inability to distinguish the stable growth of fatigue cracks, monotonous decline, and inability to distinguish the rapid growth of fatigue cracks in the second stage of stable growth, so as to improve anti-noise The effect of interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0032] The block diagram of the steps of the detection method of the present invention is shown in image 3 ,Proceed as follows;

[0033] 1) Place the self-made U-shaped electromagnetic yoke and the acoustic emission sensor in the central area of the Q235 steel member without fatigue loading in a relatively fixed position.

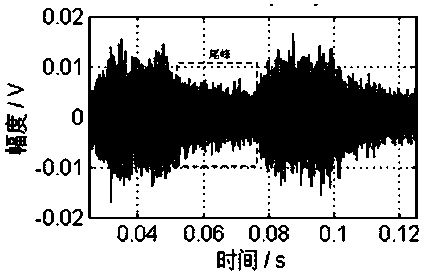

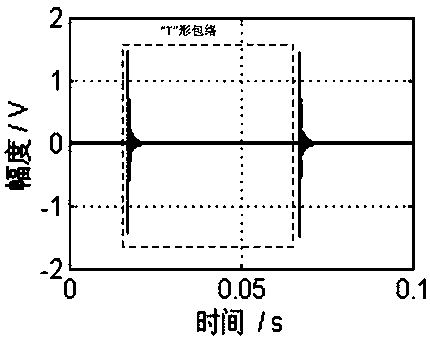

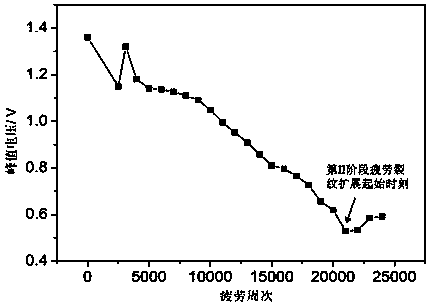

[0034] 2) Load a periodic sine wave voltage signal to the coil of the U-shaped electromagnetic yoke with a frequency of 20 Hz, where the voltage signal is generated by a function generator and amplified 10 times by a power amplifier before being input to the coil. Since the MAE signal is generated under the alternating magnetic field excited by the sine wave voltage signal, the Q235 steel member generates two identical MAE signals within one magnetization period, that is, the frequency of the MAE signal is twice the freq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com