Working face double-roadway tunneling small coal pillar reinforcement construction method

A construction method and technology of small coal pillars, applied in the direction of earthwork drilling, pillars/brackets, shaft linings, etc., can solve the problems of difficult control of the stability of small coal pillars, achieve long-term stable control, prevent slippage, and strengthen the overall Effects on sex and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

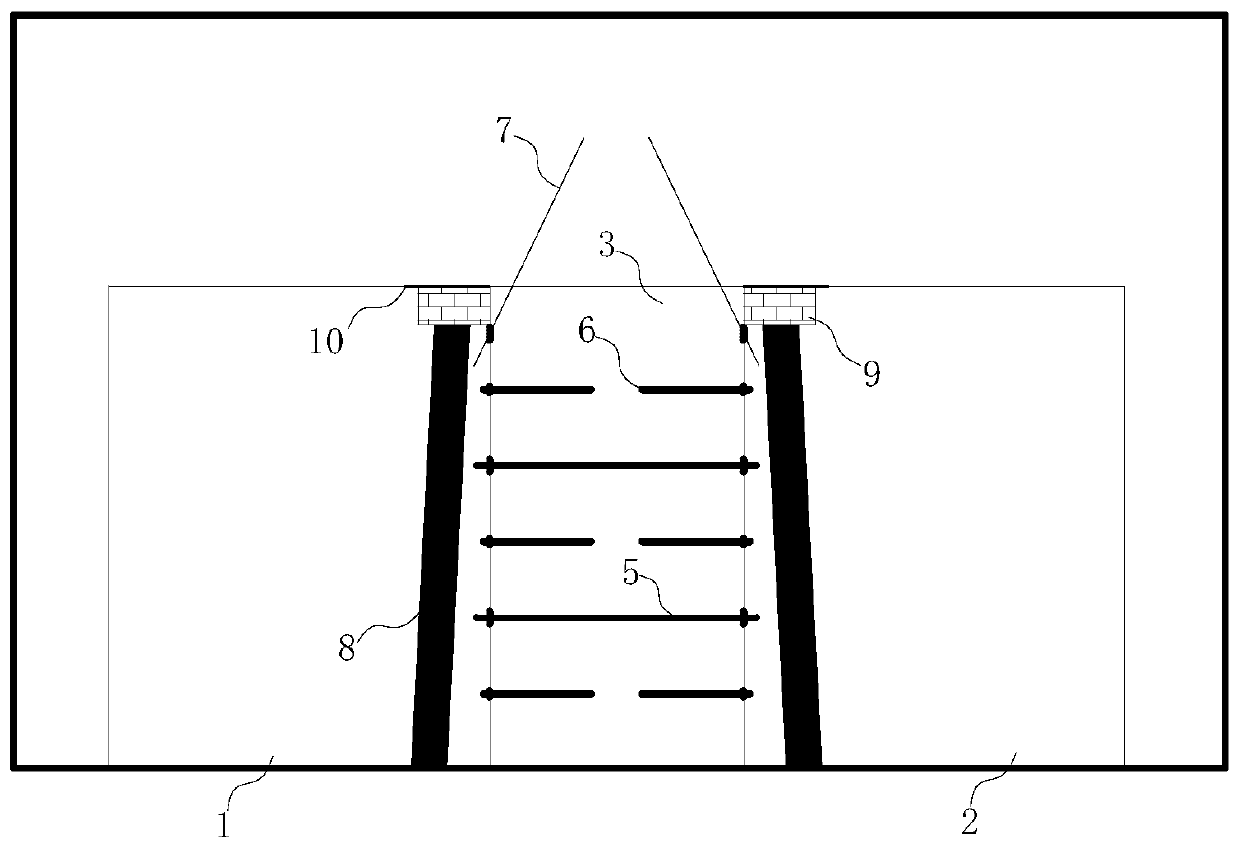

[0032] A small coal pillar reinforcement construction method for double-lane excavation, the small coal pillar reinforcement technology and construction technology for double-lane excavation, and the double-lane arrangement can solve the problem of tension in excavation replacement. Leaving small coal pillars for roadway protection improves the coal recovery rate and reduces resource loss; at the same time, the composite reinforcement support with two-way cross-piercing anchor cables as the main body can greatly improve the carrying capacity of small coal pillars and solve the problem of small coal pillars. Affected by mining, it is difficult to maintain long-term stability, which ensures the feasibility of the double-entry tunneling technology with small coal pillars. The steps of the method include:

[0033] First of all, according to the geological and mining technical conditions, use theoretical calculation, simulation and other comprehensive means to carry out the prelimi...

Embodiment 2

[0058] In this embodiment, taking the preparation roadway of the 1205 working face of a certain mine as an example, a construction method for reinforcing small coal pillars with double roadway excavation in the working face is described in detail. The designed roadway of the working face is a rectangular section with a width of 5.0m and a height of 3.2m. The direct roof of the coal seam of the excavation face is siltstone with a thickness of 3m, the basic roof is shale with a thickness of 5m, and the mining height of the coal seam is 2m.

[0059] First of all, according to the geological and mining technical conditions, reasonable relevant technical parameters are determined through theoretical calculation and simulation: it is planned to leave a small coal pillar with a width of 5m, the distance between the connecting roadway is 50m, and the distance between the two excavation faces is 5m. .8mm×5400mm, row spacing between anchor cables is 1000mm×1000mm, square arrangement. Ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com