Convenient mounting and dismounting type combined prefabricated template suitable for building floor descending plate

A dismantling and combination technology, which is applied to the on-site preparation of building components, construction, building structure, etc., can solve the problems of affecting the overall stability of the hanging form, the method is not scientific and reasonable, and the molding effect is poor, so as to overcome the The stability of the mold, the effect of avoiding the workload of chiseling, and avoiding the waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

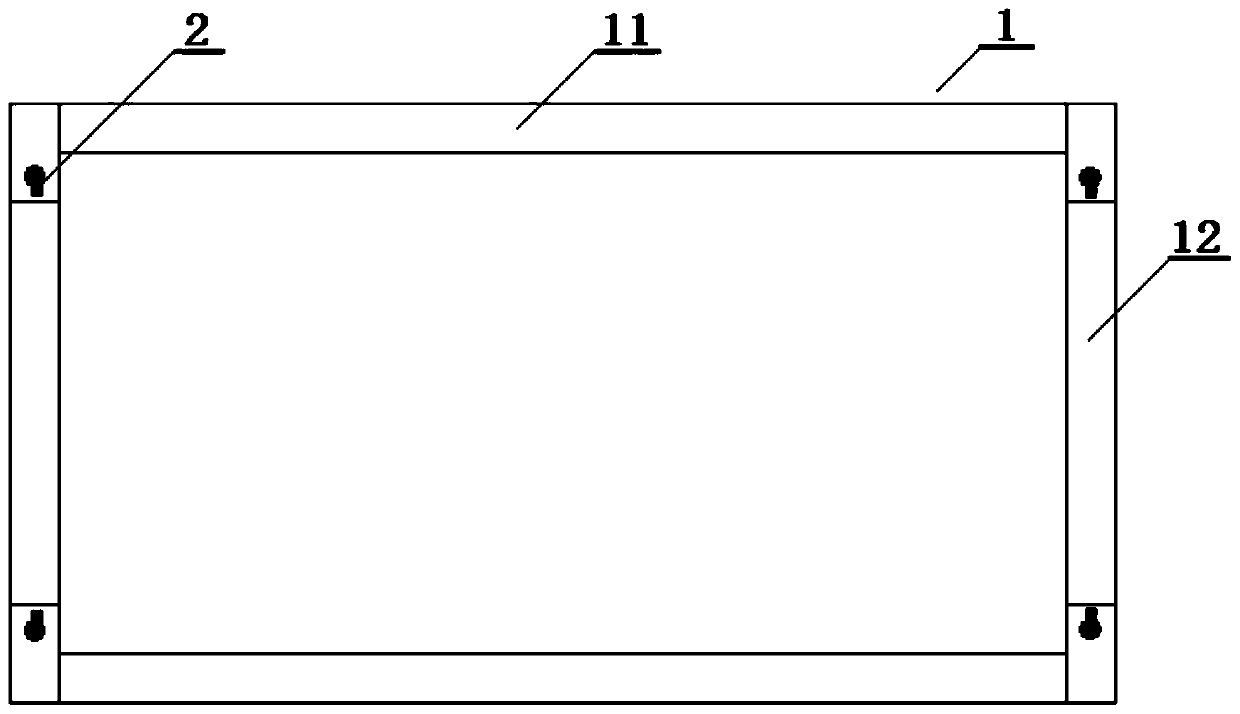

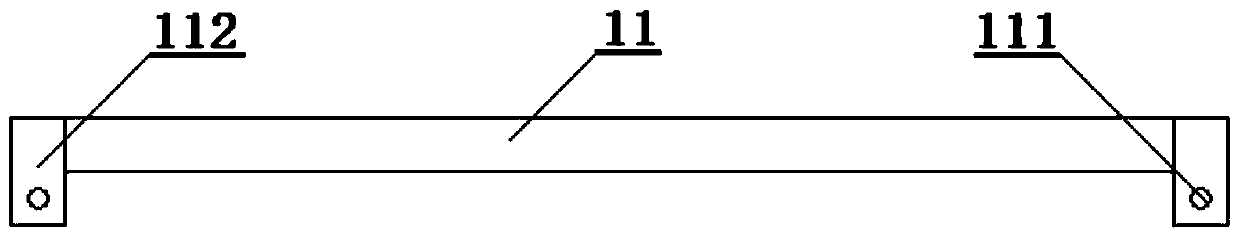

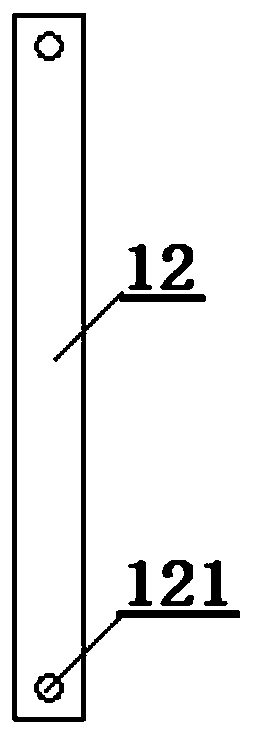

[0017] exist figure 1 , figure 2 with image 3 Among them, the convenient installation and disassembly combined prefabricated formwork suitable for the lowering plate of the building floor of the present invention, the main body includes a formwork frame 1 and a limit pin 2, and the feature is that the formwork frame 1 includes a combined formwork prefabricated by square steel plates. The horizontal steel frame plate 11 and the vertical steel frame plate 12, the limit pin 2 is served by threaded steel bars or steel pipes, wherein:

[0018] The main body of the transverse steel frame plate 11 is in the shape of a strip plate, and the two ends are respectively vertically fixed with an interconnection plate 112 provided with a limit pin hole A111;

[0019] The main body of the vertical steel frame plate 12 is in the shape of a strip, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com