Granular humic biological filler and production method and application thereof

A technology of biological filler and production method, which is applied in the direction of granular microbial carrier treatment, sustainable biological treatment, chemical instruments and methods, etc. and other problems to achieve the effect of alleviating blockage, solving negative effects, and high organic matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

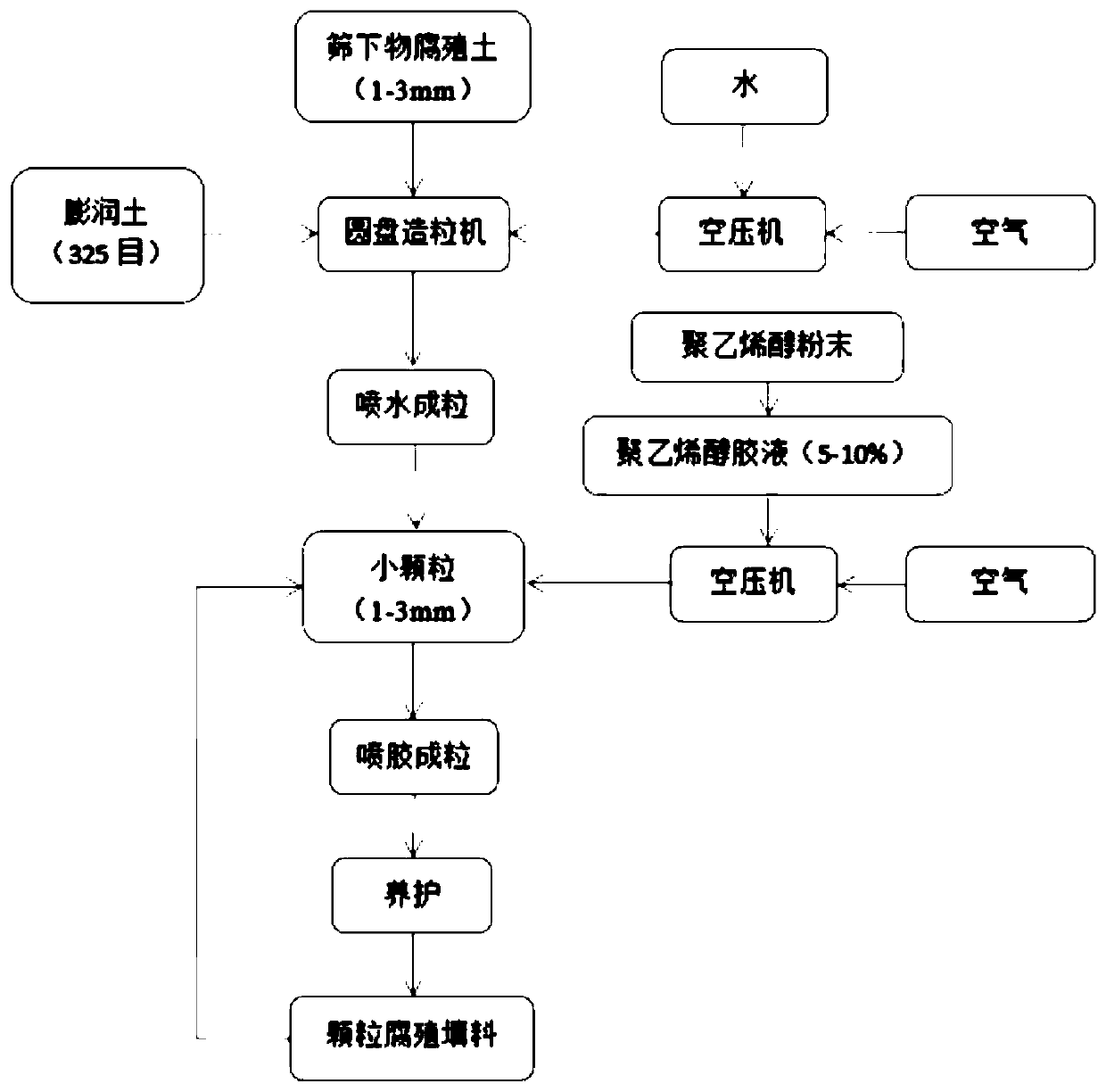

[0042] The production method of the granular humic filler of the present embodiment specifically comprises the following steps:

[0043] (1) Utilize multi-stage screening technology and equipment to obtain the humus soil under the sieve of 1~3mm, mix in the disc granulator according to the humus soil of 80% quality and the bentonite (325 orders of particle size) of 20% quality, Use an atomized water nozzle to add an appropriate amount of water to form small particles of 1 to 3 mm.

[0044] (2) Use polyvinyl alcohol powder of model 1799, dissolve it in hot water at 95°C to prepare a glue solution with a mass concentration of 5%, and use a siphon-type two-fluid air-water nozzle to spray the glue solution under the air pressure condition of an air compressor greater than 0.3MPa. Atomized and sprayed onto the small particles in the disc granulator, so that the small particles fully absorb the glue and bond with each other to gradually form large particles and obtain sufficient ini...

Embodiment 2

[0049] The production method of the granular humic filler of the present embodiment specifically comprises the following steps:

[0050] (1) Utilize multistage screening technology and equipment to obtain the humus under the sieve of 1 ~ 3mm, mix in the disc granulator according to the humus of 90% quality and the bentonite (325 orders of particle size) of 10% quality, Use an atomized water nozzle to add an appropriate amount of water to form small particles of 1 to 3 mm.

[0051] (2) Use polyvinyl alcohol powder of model 1799, dissolve it in hot water at 95°C to prepare a glue solution with a mass concentration of 7%; use a siphon type two-fluid air-water nozzle under the air pressure condition of an air compressor greater than 0.3MPa to spray the glue solution Atomized and sprayed onto the small particles in the disc granulator, so that the small particles fully absorb the glue and bond with each other to gradually form large particles and obtain sufficient initial strength....

Embodiment 3

[0055] The production method of the granular humic filler of the present embodiment specifically comprises the following steps:

[0056] (1) Utilize multi-stage screening technology and equipment to obtain the humus under the sieve of 1~3mm, mix in the disc granulator according to the humus of 85% quality and the bentonite (325 orders of particle size) of 15% quality, Use an atomized water nozzle to add an appropriate amount of water to form small particles of 1 to 3 mm.

[0057] (2) Adopt the polyvinyl alcohol powder of model 1799, dissolve with 95 ℃ of hot water and be mixed with the mass concentration and be 10% glue solution; Utilize the siphon type two-fluid air-water nozzle under the condition of air pressure greater than 0.3MPa, the described The glue is atomized and sprayed onto the small particles in the disc granulator, so that the small particles can fully absorb the glue and bond with each other to gradually form large particles and obtain sufficient initial streng...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mechanical strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com