Grinding disk of ground grinding machine driven by motor

A motor-driven, grinding machine technology, applied in the direction of grinding machine tool parts, wheels of the working part with flexibility, grinding machines, etc., can solve the problems of small grinding area, complex structure, troublesome maintenance, etc., and achieve the grinding effect Good, stable operation, fast and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

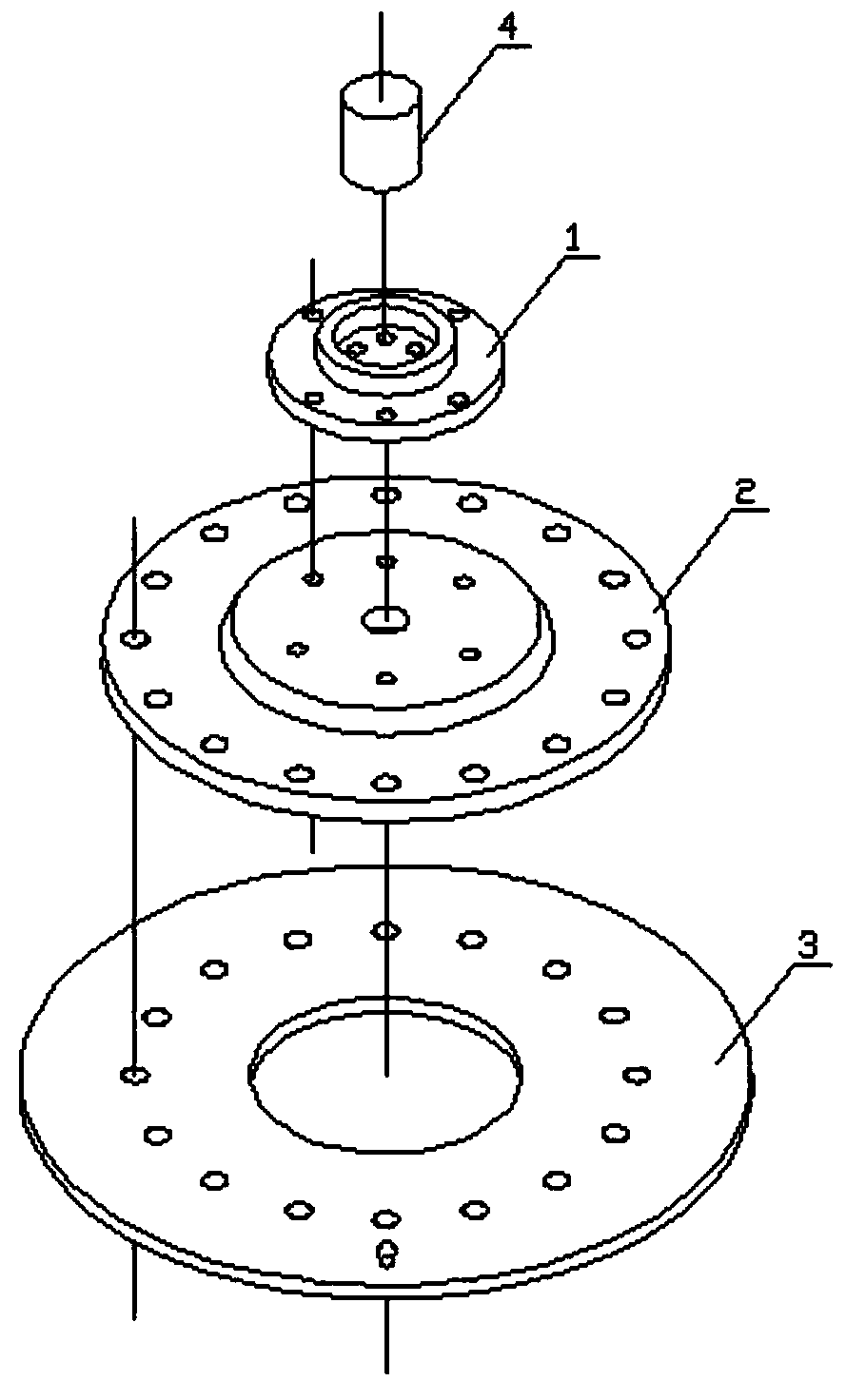

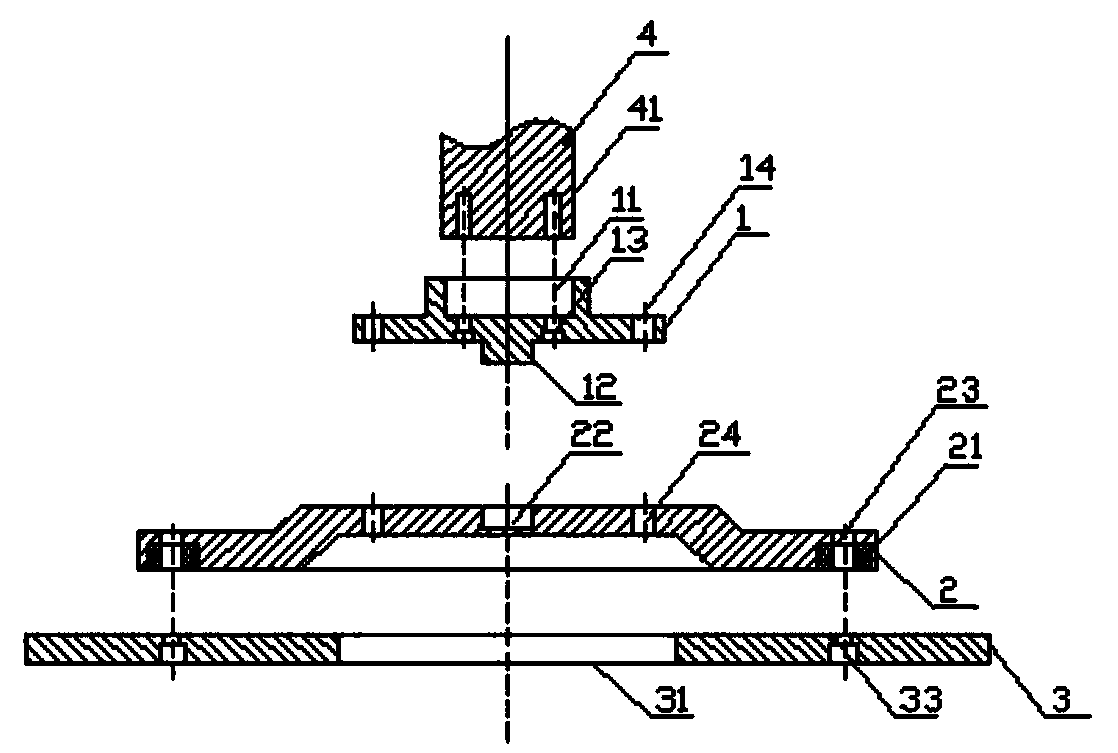

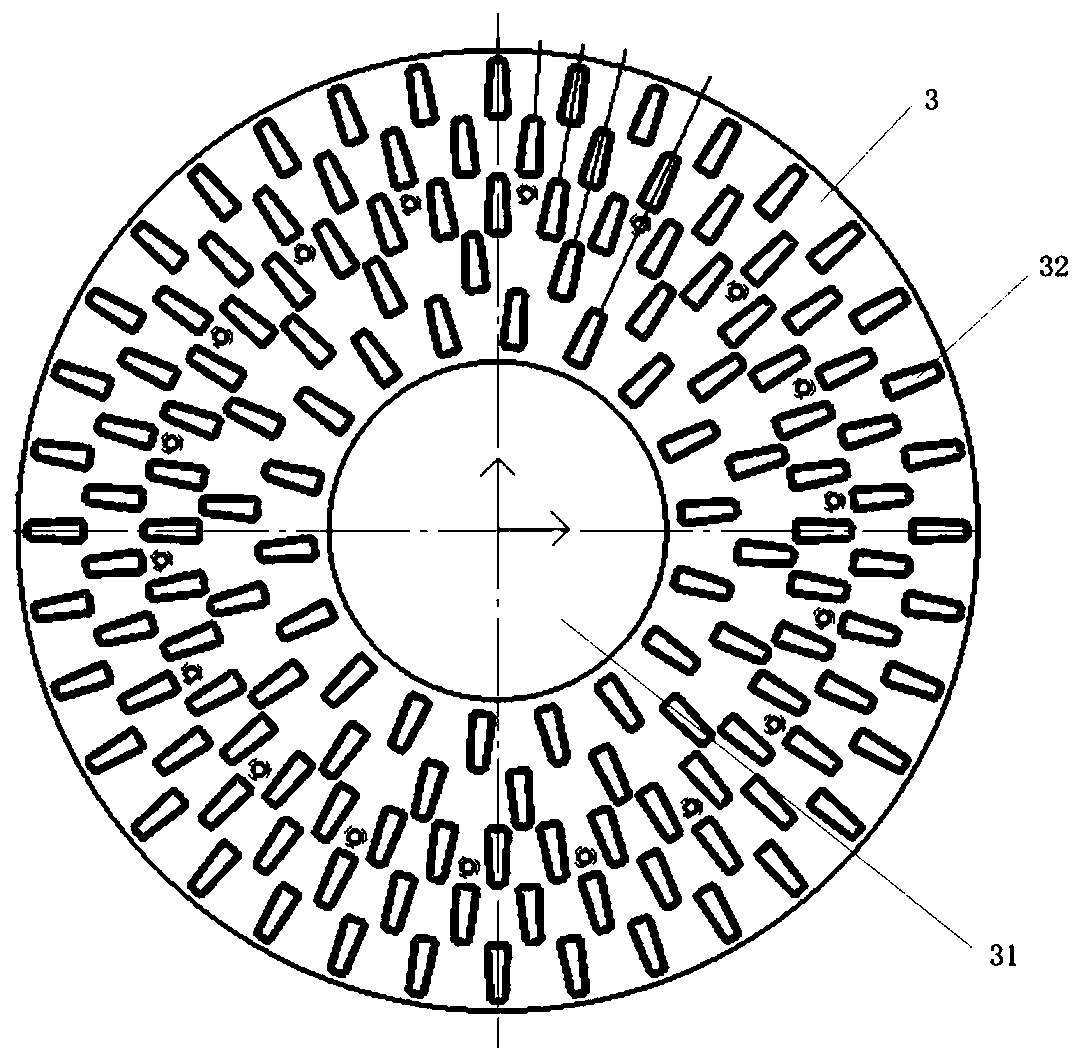

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4As shown, for a hard cement floor, the grinding disc of a motor-driven ground grinder that needs to be ground with a metal grinding block 5 includes an upper disc 1, a middle disc 2 and a chassis 3, and the chassis 3 The working surface is a single flat disk, the width of the working surface of the chassis 3 is more than 500 mm, the motor is a vertical axis direct drive motor, and the center of the upper disk 1 is fixedly connected to the output shaft 4 of the direct drive motor , the center of the middle plate 2 is fixedly connected to the upper plate 1, the center of the chassis 3 is fixed on the center plate 2, and the output shaft 4 of the vertical axis direct drive motor is The end face is provided with an upper plate bolt threaded hole 41, the upper plate 1 is in the shape of a two-step circular platform, and the center of the upper surface of the upper stepped circular platform is provided with an output sha...

Embodiment 2

[0032] Such as figure 1 , figure 2 , Figure 5 and Figure 6 As shown, for the grinding of the floor with a low degree of ground hardness, it is necessary to use resin grinding blocks or ceramic grinding blocks for grinding. The grinding disc of a motor-driven ground grinder includes upper disc 1, middle disc Disk 2 and chassis 3, the working surface of the chassis 3 is a single flat disk, the width of the working surface of the chassis 3 is more than 500mm, the motor is a vertical axis direct drive motor, and the center of the upper disk 1 is circumferentially It is fixedly connected to the output shaft 4 of the direct drive motor, the center of the middle plate 2 is fixedly connected to the upper plate 1, and the center of the chassis 3 is fixed to the center of the middle plate 2. The lower end surface of the output shaft 4 of the vertical axis direct drive motor is provided with an upper plate bolt threaded hole 41, the upper plate 1 is in the shape of a two-step circu...

Embodiment 3

[0035] Such as figure 1 , figure 2 , Figure 7 and Figure 8 As shown, for the ground that has been roughly ground, when only smooth grinding is required, it is necessary to use animal hair pads or felt grinding blocks for grinding. The grinding disc of a motor-driven ground grinder includes upper disc 1, middle disc Disk 2 and chassis 3, the working surface of the chassis 3 is a single flat disk, the width of the working surface of the chassis 3 is more than 500mm, the motor is a vertical axis direct drive motor, and the center of the upper disk 1 is circumferentially It is fixedly connected to the output shaft 4 of the direct drive motor, the center of the middle plate 2 is fixedly connected to the upper plate 1, and the center of the chassis 3 is fixed to the center of the middle plate 2. The lower end surface of the output shaft 4 of the vertical axis direct drive motor is provided with an upper plate bolt threaded hole 41, the upper plate 1 is in the shape of a two-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com