Crankshaft machining method

A technology of crankshaft processing and crankshaft, which is applied in the direction of crankshaft, shaft, shaft and bearing, etc., which can solve the problems of low processing efficiency and inability to ensure processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

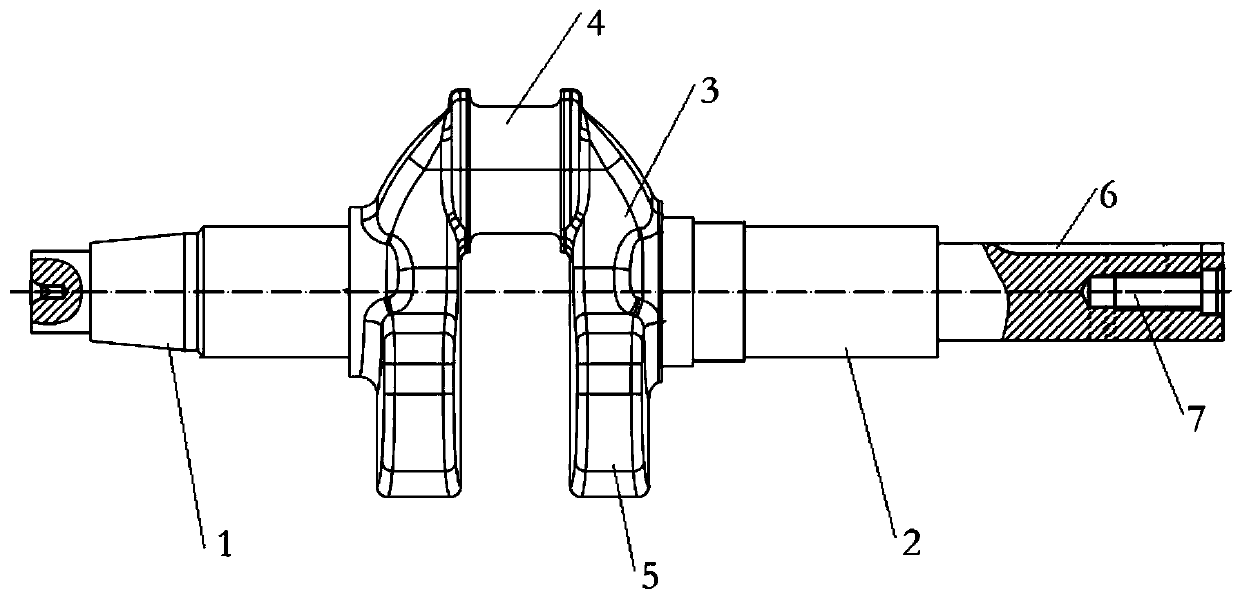

[0034] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0035] see figure 1Shown: a crankshaft machining method, including the step of obtaining a crankshaft blank; it is characterized in that it also includes the following steps: a) machining a center hole on the outer end faces of the input shaft section and the output shaft section of the crankshaft; b rough turning and finishing turning Crankshaft input shaft section and rough turning and finishing crankshaft output shaft section; c Turning the inner sides of the two crank arms and the main journal, and making the length dimension of the main journal between the inner surfaces of the two crank arms match the design length dimension; d Machining The keyway of the crankshaft output shaft section and the input shaft section; e quenching the main journal on the crankshaft; f straightening the crankshaft after quenching in step e; g corresponding to the position of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com