A kind of bearing roller cold forging production process

A production process and technology of bearing rollers, which are used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc., can solve the problems of insufficient tight organization of bearing rollers, low material utilization, time-consuming and labor-intensive, etc. High efficiency, high material utilization, avoiding the effect of later maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

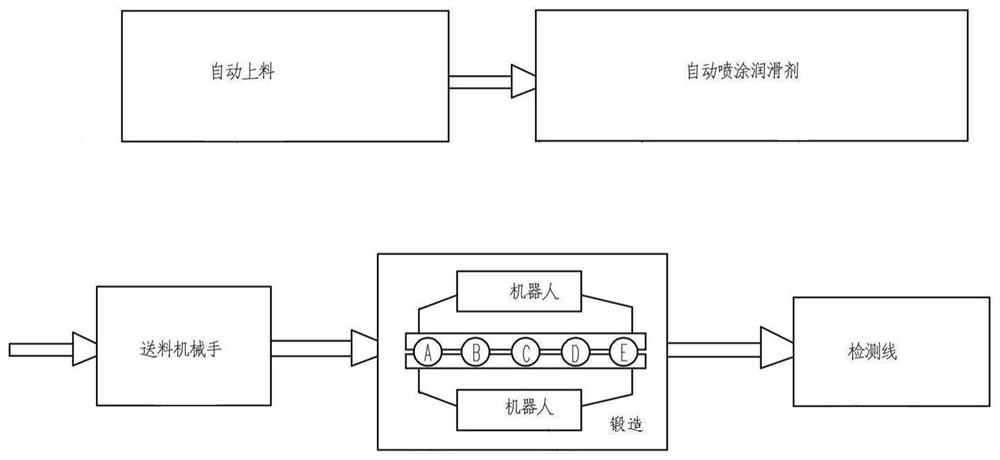

[0031] Such as figure 1 , a bearing roller cold forging production process, the specific steps are as follows:

[0032] a) feeding;

[0033] b) Spray lubricant on the steel bar;

[0034] c) Multi-station forging at room temperature;

[0035] d) Forging surface quality inspection;

[0036] e) Grinding after quenching;

[0037] f) Enter the detection line detection.

[0038] In order to further explain this embodiment, it should be noted that in step c), the specific steps are:

[0039] , the robot sends the steel bar vertically into the cavity A, one end pre-forges the boss, and the other end pre-forges the fillet;

[0040] , the robot flips the steel bar 180°, sends it vertically into cavity B, with the pre-forged boss facing down, and performs taper forging on the top of the steel bar. The length of the taper forging is more than half of the total length, and the other end Forging fillets; at the same time, the second piece of steel bar enters cavity A for processi...

Embodiment 2

[0046] A bearing roller cold forging production process, the specific steps are as follows:

[0047] a) feeding;

[0048] b) Spray lubricant on the steel bar;

[0049] c) Multi-station forging at room temperature;

[0050] d) Forging surface quality inspection;

[0051] e) Grinding after quenching;

[0052] f) Enter the detection line detection.

[0053] In order to further explain this embodiment, it should be noted that in step c), the specific steps are:

[0054] , the robot sends the steel bar vertically into the cavity A, one end pre-forges the boss, and the other end pre-forges the fillet;

[0055] , the robot flips the steel bar 180°, sends it vertically into cavity B, with the pre-forged boss facing down, and performs taper forging on the top of the steel bar, wherein the length of the taper forging is more than half of the total length, and the other end Forging fillets; at the same time, the second piece of steel bar enters cavity A for processing;

[0056...

Embodiment 3

[0061] A bearing roller cold forging production process, the specific steps are as follows:

[0062] a) feeding;

[0063] b) Spray lubricant on the steel bar;

[0064]c) Multi-station forging at room temperature;

[0065] d) Forging surface quality inspection;

[0066] e) Grinding after quenching;

[0067] f) Enter the detection line detection.

[0068] In order to further explain this embodiment, it should be noted that in step c), the specific steps are:

[0069] , the robot sends the steel bar vertically into the cavity A, one end pre-forges the boss, and the other end pre-forges the fillet;

[0070] , the robot flips the steel bar 180°, sends it vertically into cavity B, with the pre-forged boss facing down, and performs taper forging on the top of the steel bar. The length of the taper forging is more than half of the total length, and the other end Forging fillets; at the same time, the second piece of steel bar enters cavity A for processing;

[0071] , the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com