Condensation treatment method and device for removing siloxane components in biomass gas

A treatment method and technology for siloxane, applied in separation methods, chemical instruments and methods, dispersion particle separation, etc., can solve the problems of poor siloxane treatment and high cost, and achieve the effect of improving efficiency and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

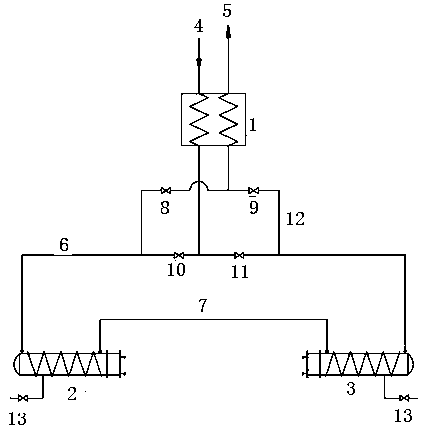

[0026] Such as Figure 1-2 shown.

[0027] A condensation treatment method for removing siloxane components in biomass gas, comprising the following steps:

[0028] First, set up a heat exchanger for the entry and exit of siloxane-containing biomass gas for heat recovery and pre-cooling of intake air;

[0029] Secondly, two condensers are set up, and the siloxane-containing biomass gas enters the first condenser and the second condenser in turn through the control valve, and at the same time, the first condenser and the second condenser work as the evaporator and defrost respectively. device status.

[0030] (1) if figure 1 shown. The intake air passes through the heat exchanger 1 and the outlet air for heat recovery to achieve pre-cooling of the intake air, and then through valve control, the first condenser 2 > the second condenser 3 and the second condenser 3 > the first condenser 2 Flow state for switching operation.

[0031] (2) When the first valve 8 and the fourth...

Embodiment 2

[0038] Such as Figure 1-2 shown.

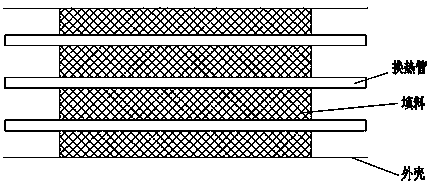

[0039] A condensation treatment device for removing siloxane components in biomass gas, which includes a heat exchanger 1, a first condenser 2 and a second condenser 3, such as figure 1 shown. The heat exchanger 1 is provided with an inlet pipeline 4 and an outlet pipeline 5, and the inlet pipeline 4 communicates with the inlet ends of the first condenser 2 and the second condenser 3 through the inlet pipeline 6, and the first condenser 2 It communicates with the outlet end of the second condenser 3 through a connecting pipe 7, and a third valve 10 and a fourth valve 11 are installed on the inlet pipe 6 communicating with the first condenser 2 and the second condenser 3, and The connection point between the air pipeline 4 and the air inlet pipe 6 is located between the third valve 10 and the fourth valve 11; the air inlet pipe 6 on the outside of the third valve 10 and the fourth valve 11 is connected with a return air pipe 12 respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com