Manufacturing method of assembly of fixed bridge and columnar attachment of implantation screw

A manufacturing method and technology of attachments, applied in the direction of processing and manufacturing, manufacturing tools, manufacturing auxiliary devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

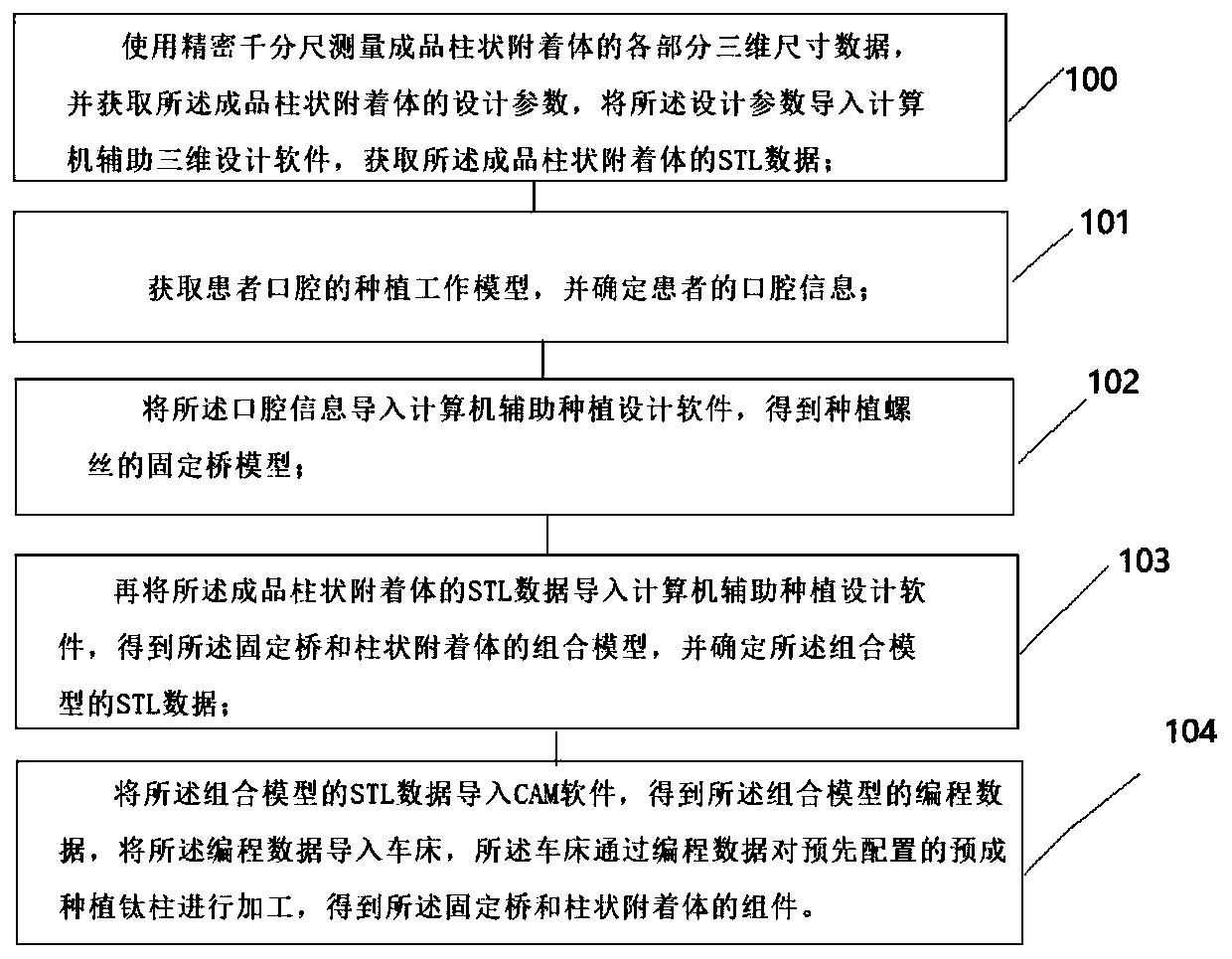

[0074] as attached figure 1 Described, a flow chart of a method for manufacturing components of a fixation bridge and a columnar attachment of implant screws, including:

[0075] Step 100: Use a precision micrometer to measure the three-dimensional dimension data of each part of the finished columnar attachment, and obtain the design parameters of the finished columnar attachment, import the design parameters into computer-aided three-dimensional design software, and obtain the 3D dimensions of the finished columnar attachment. STL data; the finished columnar attachment model is a human oral cavity tooth model.

[0076] Step 101: Obtain the implant working model of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com