Power equipment temperature prediction method based on PSO-LSSVM online learning

A technology of power equipment and prediction method, which is applied in the field of power equipment temperature prediction based on PSO-LSSVM online learning, can solve the problems that it is not easy to predict the development trend of equipment temperature, the temperature cannot be obtained in real time, and the calculation efficiency is high, so as to improve the temperature prediction Accuracy and operating efficiency, ensuring generalization ability, and improving security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The temperature prediction method of power equipment based on PSO-LSSVM online learning includes the following steps:

[0049] Step 1: Through the optical fiber sensor, transmit the temperature data of electrical equipment collected in real time to the background system every 5 minutes, and then preprocess the data to remove the influence of noise.

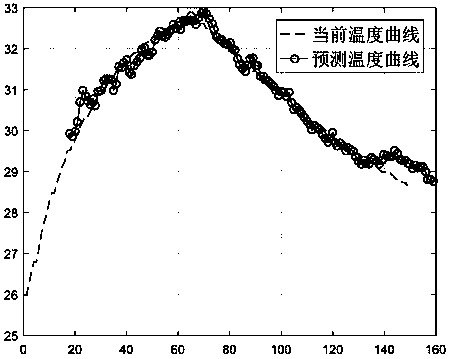

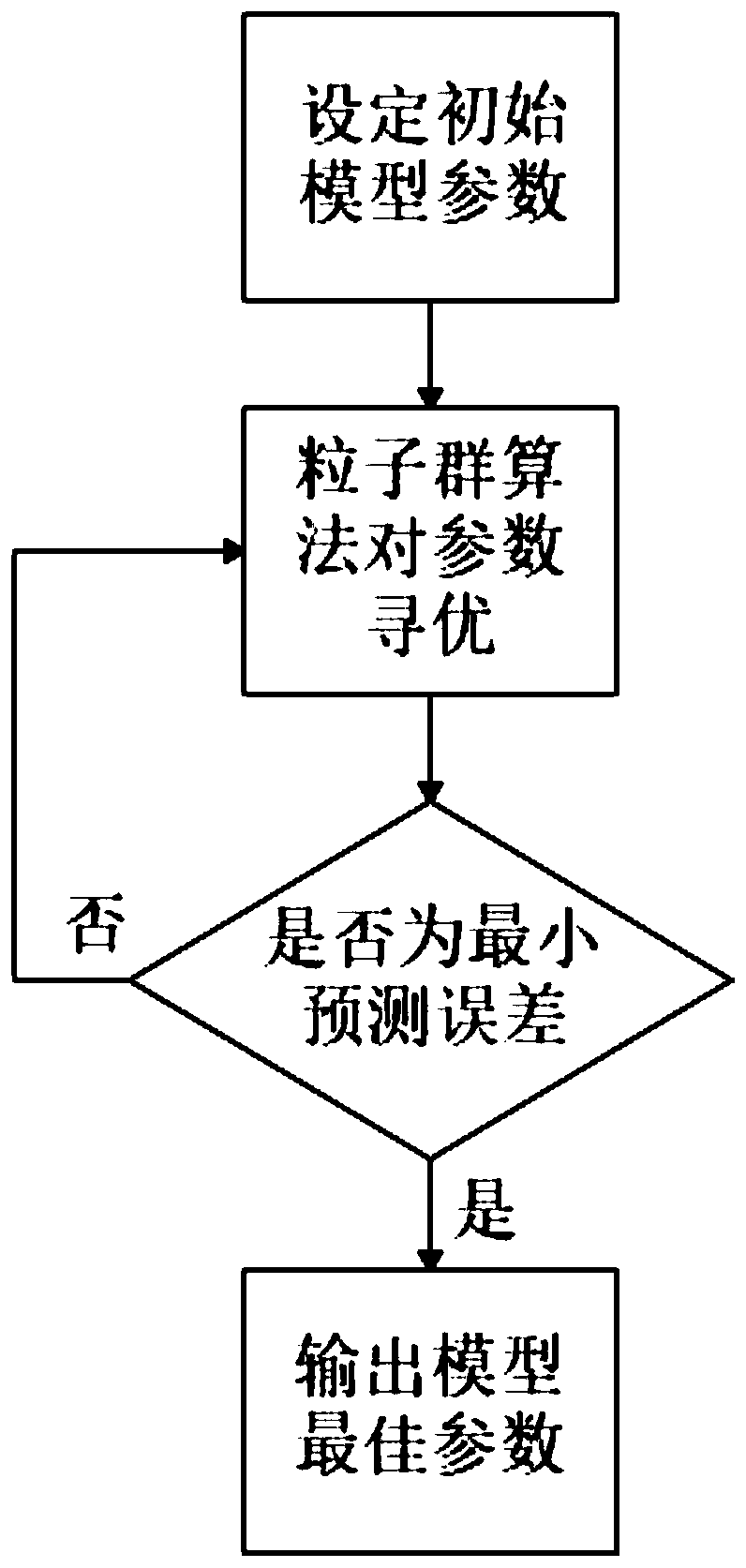

[0050] Step 2: Construct an initial training sample according to the order of the collected time series, use 8 temperature input values as the input layer of the LSSVM model, and the temperature value at the next moment as the output layer, and set the total number of initial samples N to 200 groups. Use particle swarm optimization (PSO) to optimize the parameters of the LSSVM model to obtain an optimal initial prediction model, such as figure 1 shown.

[0051] Step 3: On the basis of the initial prediction model, predict the temperature data at the next moment, and compare it with the real-time temperature data collecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com