Reinforced concrete structure crack depth detection method and device based on horizontal shear waves

A horizontal shear wave, reinforced concrete technology, applied in measuring devices, processing response signals of detection, using ultrasonic/sonic/infrasonic waves and other directions, can solve problems such as fast attenuation of compression waves, reduced signal-to-noise ratio of detection signals, and inability to detect , to achieve the effect of low attenuation rate, high signal-to-noise ratio of detection signal, and improved detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

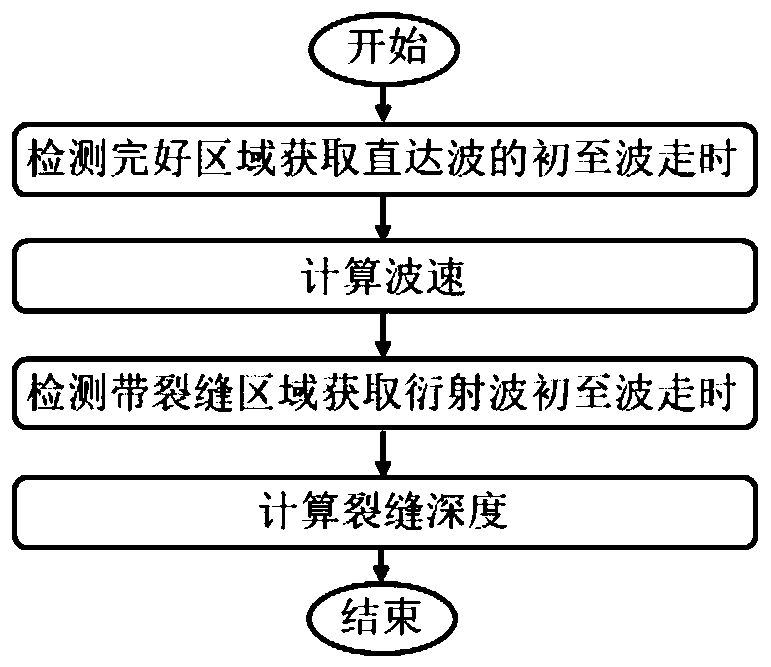

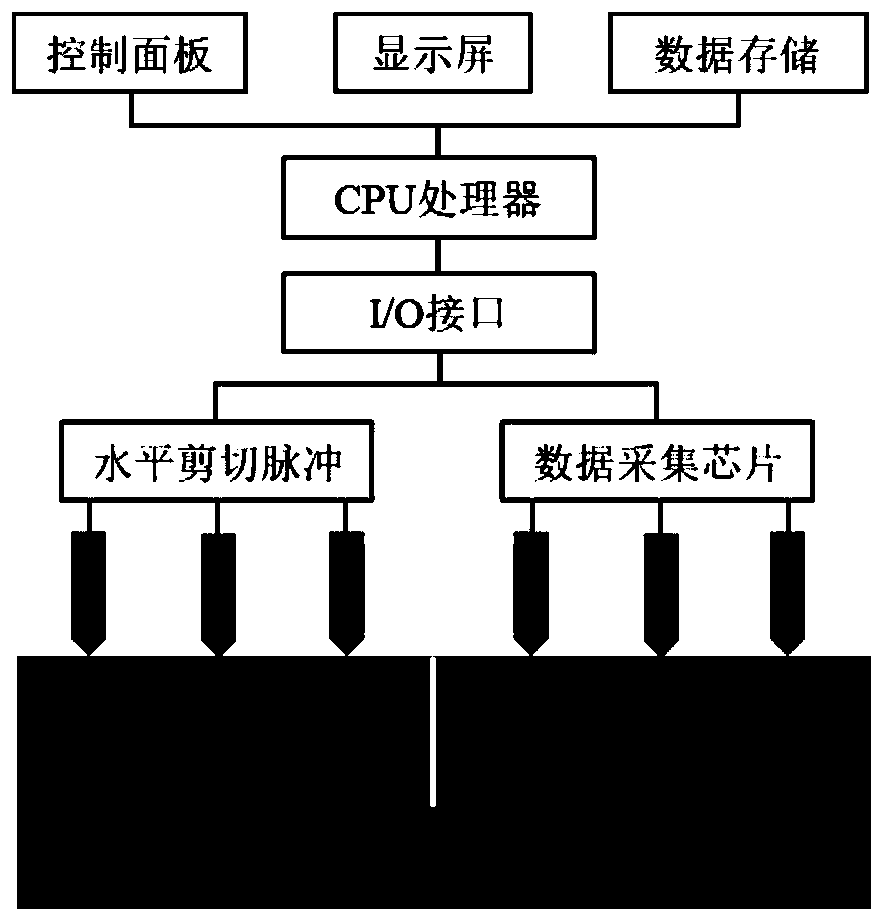

[0040] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0041] The detection data of a concrete bridge slab with a crack is used to verify the validity of the method, and the true depth of the crack is 94 mm.

[0042] The specific implementation is as follows:

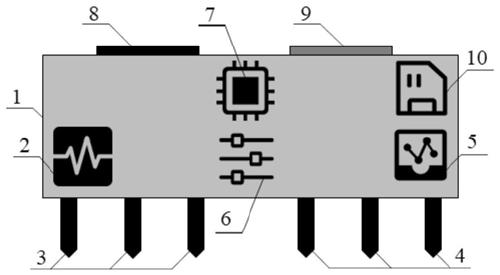

[0043] (1) choose the intact area on the concrete bridge plate, utilize the device of the present invention ( image 3 ) for testing, it is necessary to ensure good contact between the wave source transmitting end of the equipment and the sensor receiving end, and to obtain the reflected wave of the slab bottom in the intact concrete area (see Figure 4 ), using the Hilbert transform to obtain the absolute amplitude information of the wave (see Figure 5 ), extract the reflected wave travel time from the absolute amplitude information, that is, the propagation time corresponding to the point where the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com