Complex combined heat and power generation heat supply system based on low-temperature waste heat recovery and electric heating load adjusting method

A heating system, low-temperature waste heat technology, applied in heating systems, space heating and ventilation details, household heating, etc., can solve problems such as the stability of the operating conditions of thermal power units that are not considered

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

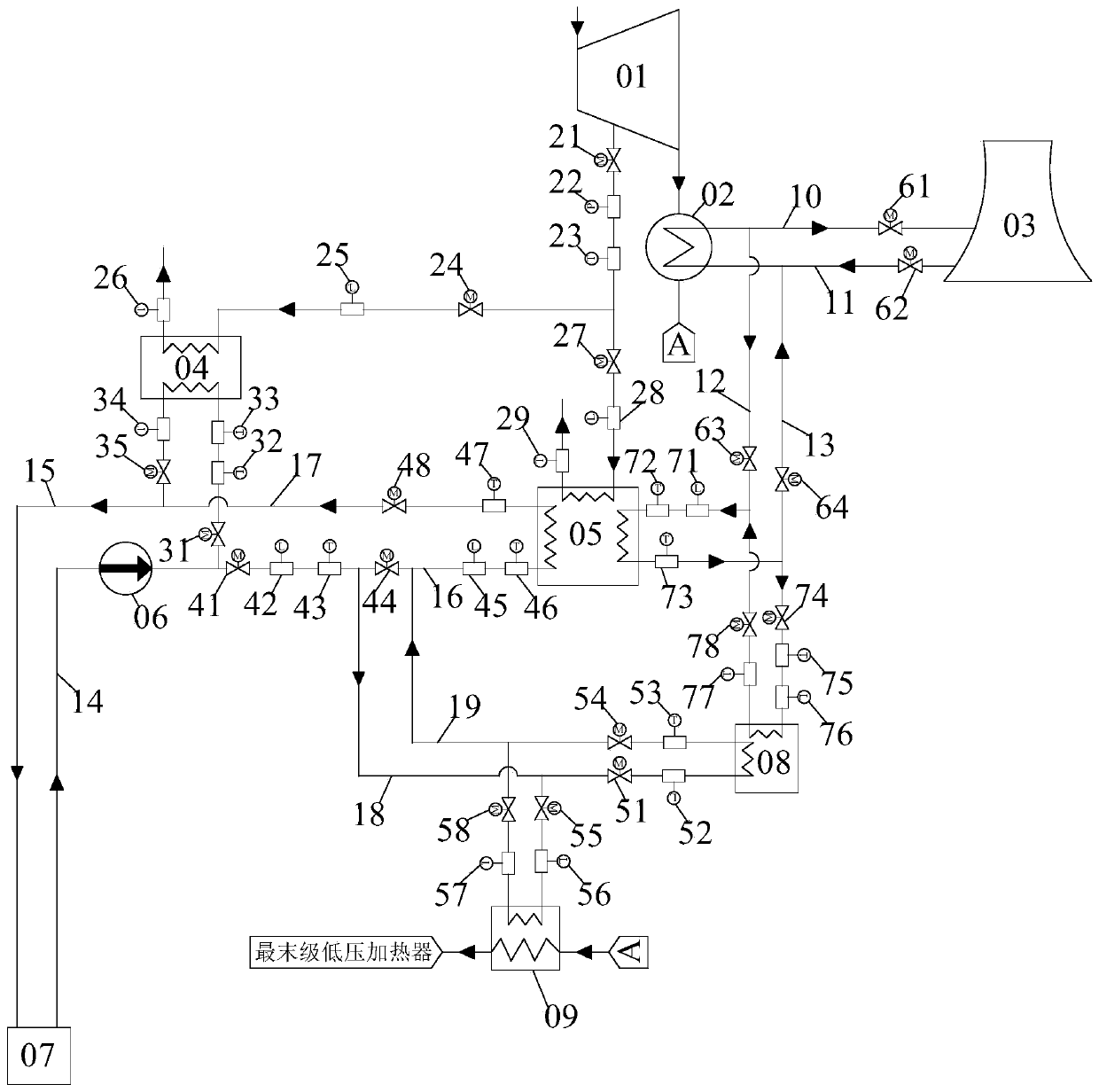

[0083] see figure 1 , this embodiment relates to a complex heat and power cogeneration heating system based on low-temperature waste heat recovery and an electric heating load adjustment method. type heat pump 05, heat exchange station 07, No. 1 water-water heat exchanger 08 and No. 2 water-water heat exchanger 09, the exhaust port of thermoelectric unit 01 is connected to the exhaust steam inlet of The condensed water outlet is connected to the condensed water inlet of the No. 2 water-to-water heat exchanger 09, and the steam extraction port of the thermal power unit 01 is connected to the steam inlet of the first station 04 of the heating network and the driving steam inlet of the absorption heat pump 05, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com