Micro-space chimney shaking-stopping device

A micro-space and chimney technology, which is applied to building components, building types, and earthquake resistance, can solve problems such as limited installation space, inability to install anti-sway devices, and small net distance between inner and outer cylinders, so as to reduce the flow rate of smoke and realize Environmental value and economic value, the effect of ensuring the quality of anti-sway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

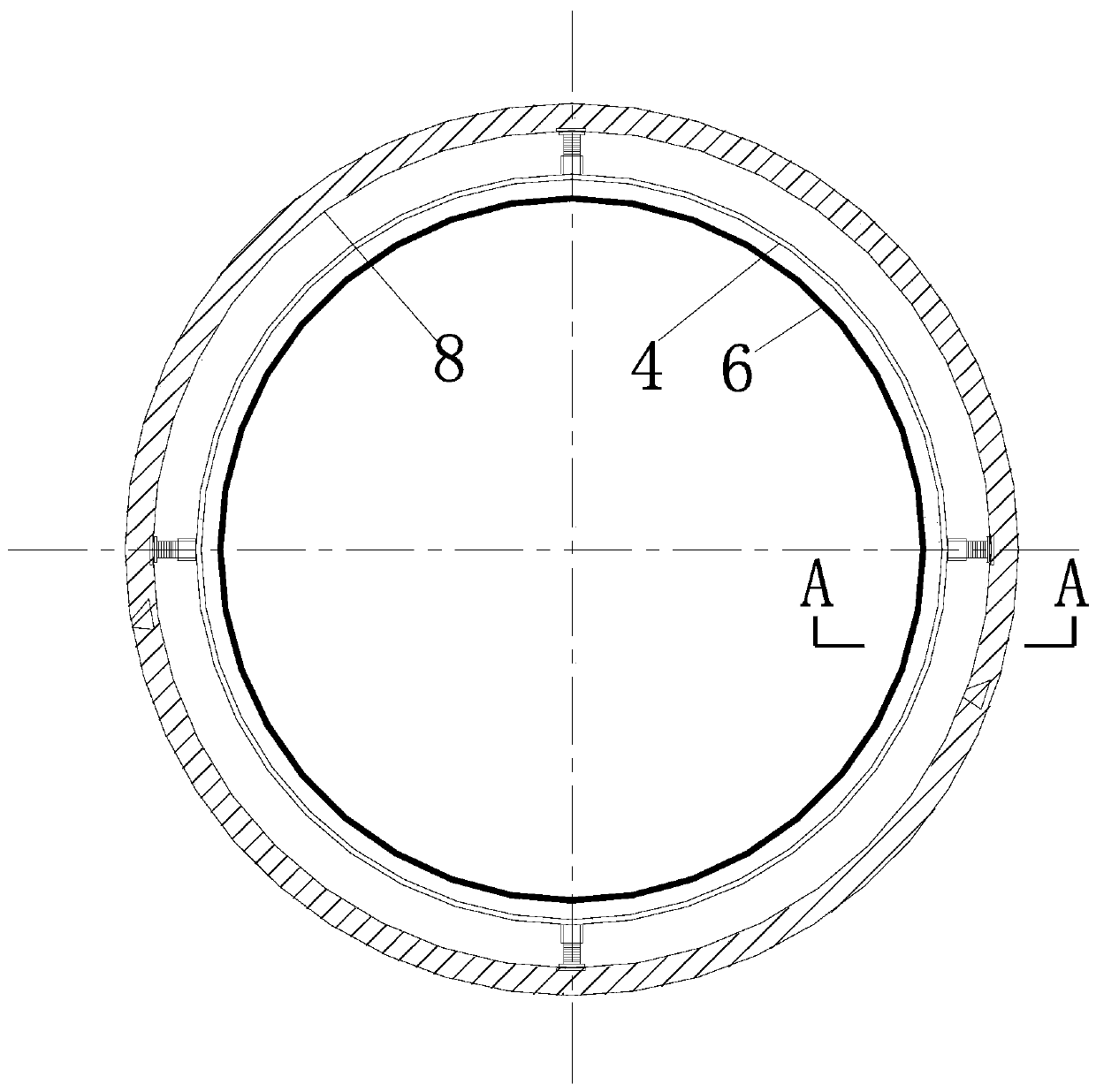

[0028] figure 1 It is the basic type of the present invention. exist figure 2 In the embodiment, the bolt 2, the anti-sway pressure-bearing end plate 3a, and the polytetrafluoroethylene anti-sway and resistance-reducing end plate 3b together form a "bolt-type pressure bar", which has the "slide rail" function of a traditional anti-sway device, in which the bolt 2 It is welded to the anti-sway pressure end plate 3a, and the polytetrafluoroethylene anti-sway resistance end plate 3b is fixed on the anti-sway pressure end plate 3a. It has high compressive strength, smooth surface and small friction coefficient, which can reduce the vertical sliding resistance. The anti-sway pressure-bearing guide steel plate 7 is fixed on the outer cylinder wall 8, and is vertically parallel to the anti-sway pressure-bearing end plate 3a, and is used to transmit the horizontal force of the "bolt type pressure rod" to the outer cylinder wall 8. At the same time, " The polytetrafluoroethylene an...

Embodiment 2

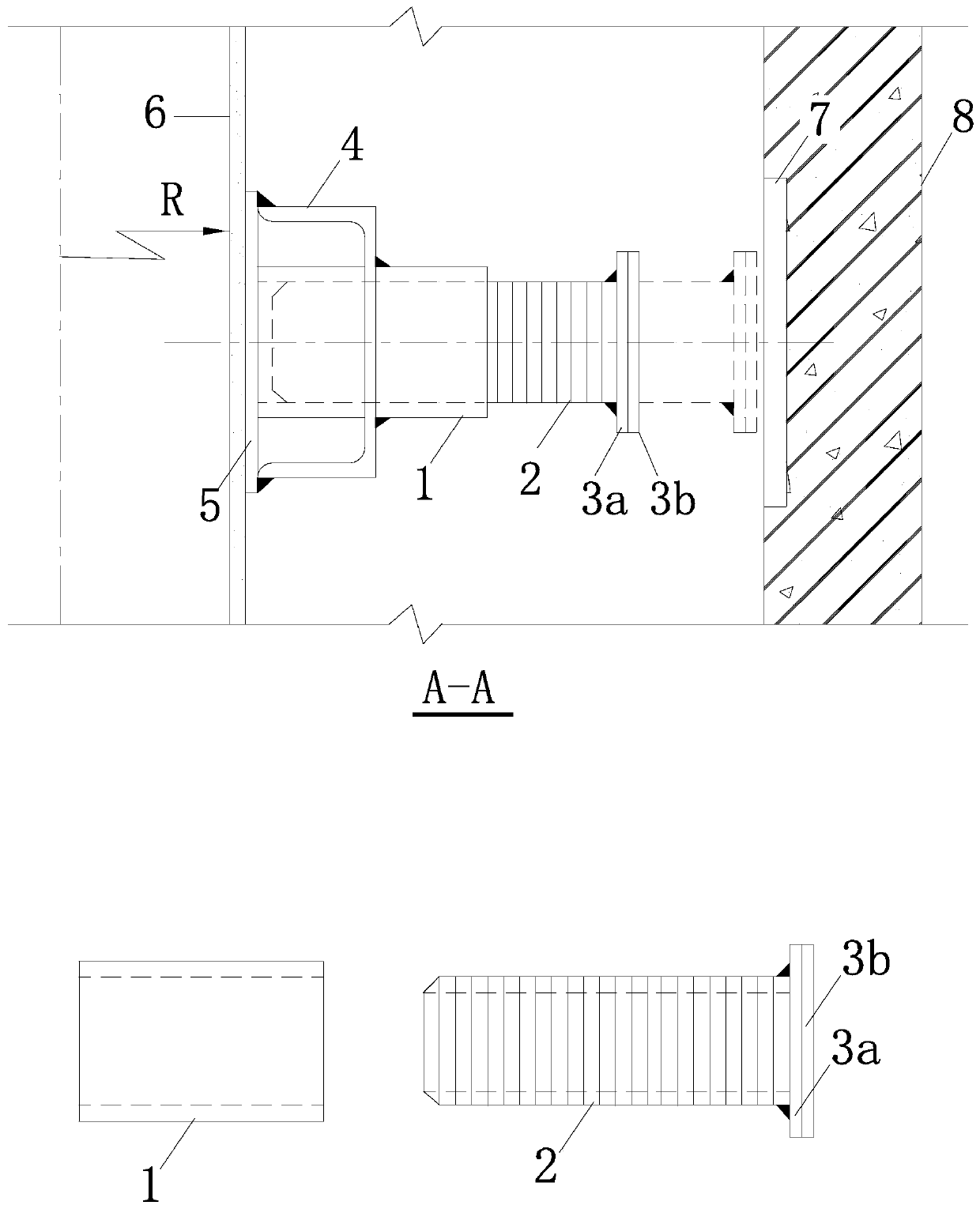

[0033] image 3 It is an expanded application type of the present invention. For use with steel platform beam chimneys or steel tower chimneys. The connecting steel plate 9 is welded on the platform steel beam 10, and the cylindrical nut 1 is fixed together with the platform steel beam 10. The bolt 2 can go deep into the interior of the platform steel beam 10 through the cylindrical nut 1 until it is close to the surface of the platform steel beam 10, and the maximum The requirement for the distance between the platform steel beam 10 and the inner cylinder is minimized, and the limitation of the platform size is reduced.

[0034] After the inner cylinder is installed, the bolt 2 is rotated to the surface of the stiffening ring 4 of the inner cylinder, and tightly attached to it, and the installation of the anti-sway device is completed.

[0035] Additional Notes: The platform steel beam 10 in the embodiment of the present invention is in the form of channel steel, and the cy...

Embodiment 3

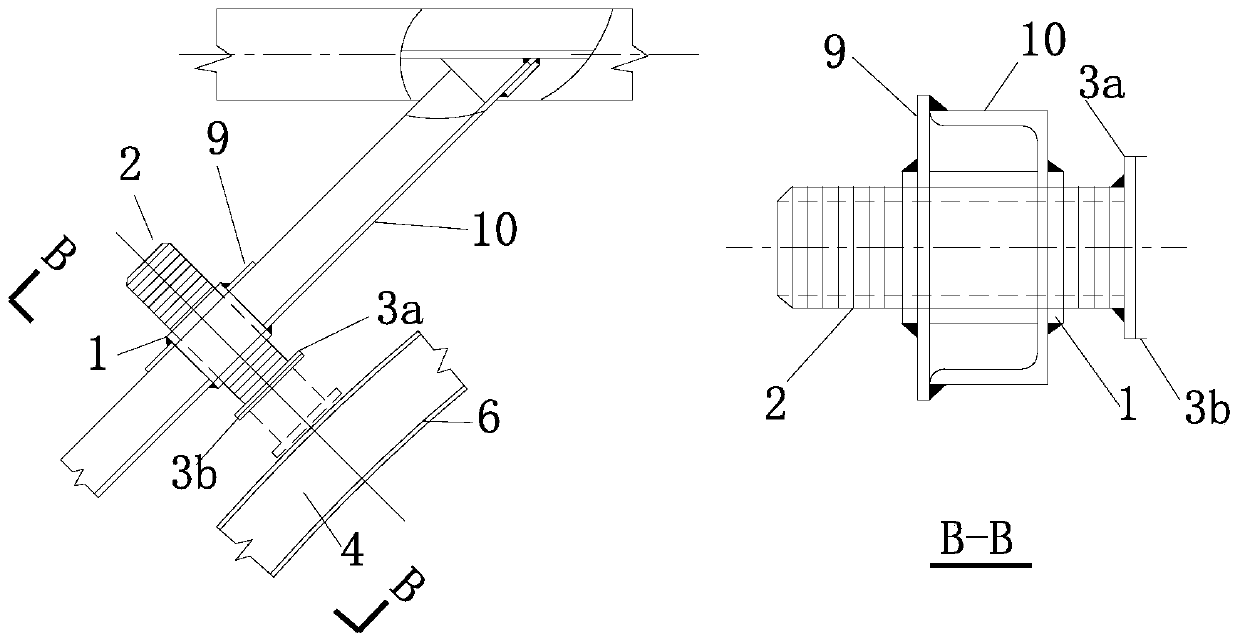

[0037] Figure 4 It is another expanded application type of the present invention. It is mainly suitable for the situation where the inner and outer cylinders of the chimney have a large space, but it is not suitable, unsatisfactory or not equipped with an anti-sway platform, and it is especially suitable for the renovation project of the old chimney. Due to high-altitude construction, the construction errors of the wall thickness, radius, and roundness of the outer wall 8 of the chimney are generally large, and the actual size of the chimney section and the design drawings have a large error, which can easily cause the size of the anti-sway rod to fail to meet the actual installation. needs. By adopting the present invention, the dimensional error can be adjusted by enlarging the bolt length, which greatly improves the application range of this type of anti-sway device.

[0038] exist Figure 4 In the embodiment, the cylindrical nut 1 is fixed on the outer cylinder wall 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com