Alkaline zinc-iron alloy electroplating liquid and electroplating process thereof

A zinc-iron alloy and electroplating technology, applied in the direction of plating tank, electrolytic process, electrolytic components, etc., can solve the problems of slow zinc-iron alloy electroplating speed, defects of electroplating layer, wrinkles, etc., to prevent uneven electroplating effect and speed up electroplating speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

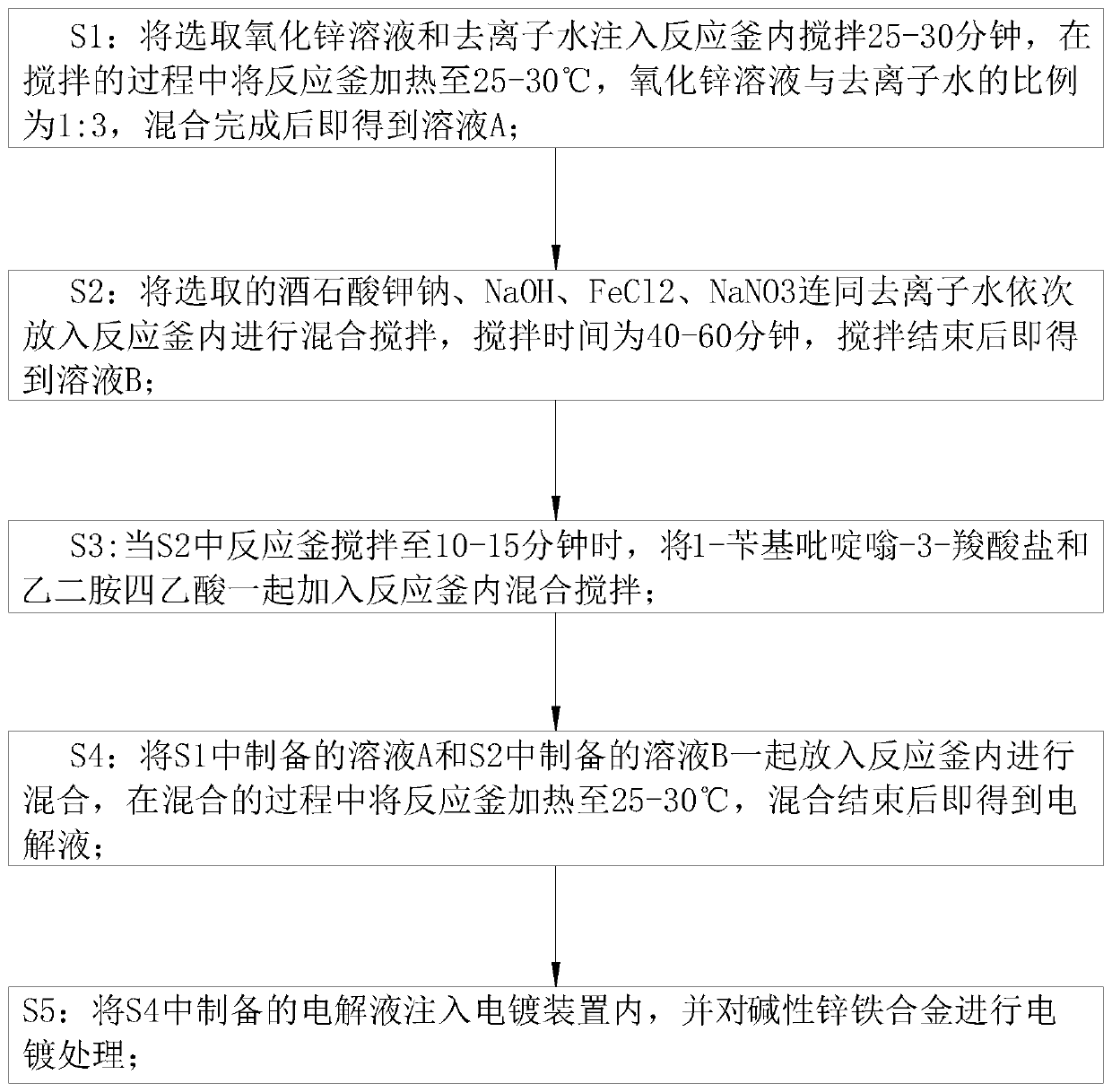

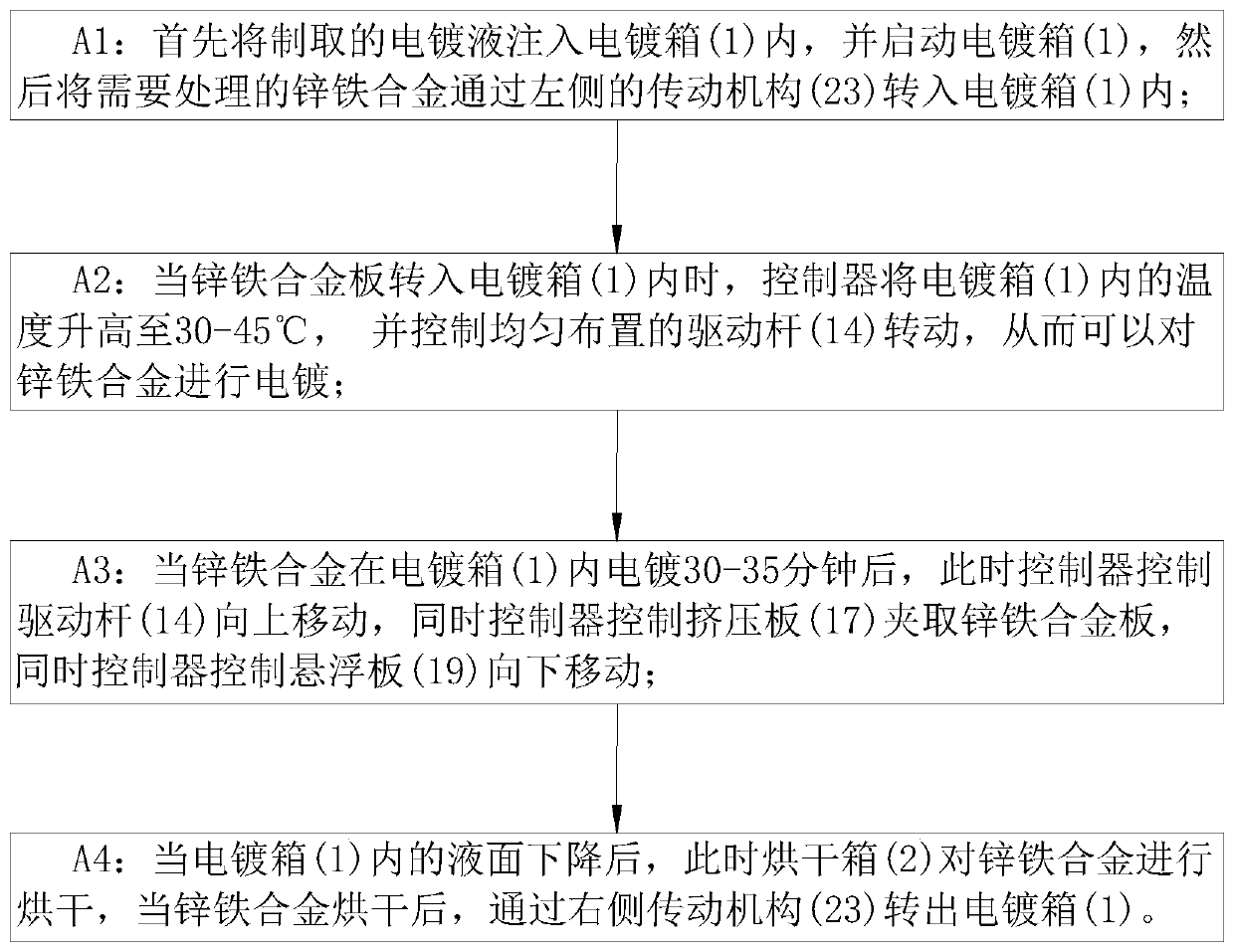

Method used

Image

Examples

Embodiment approach

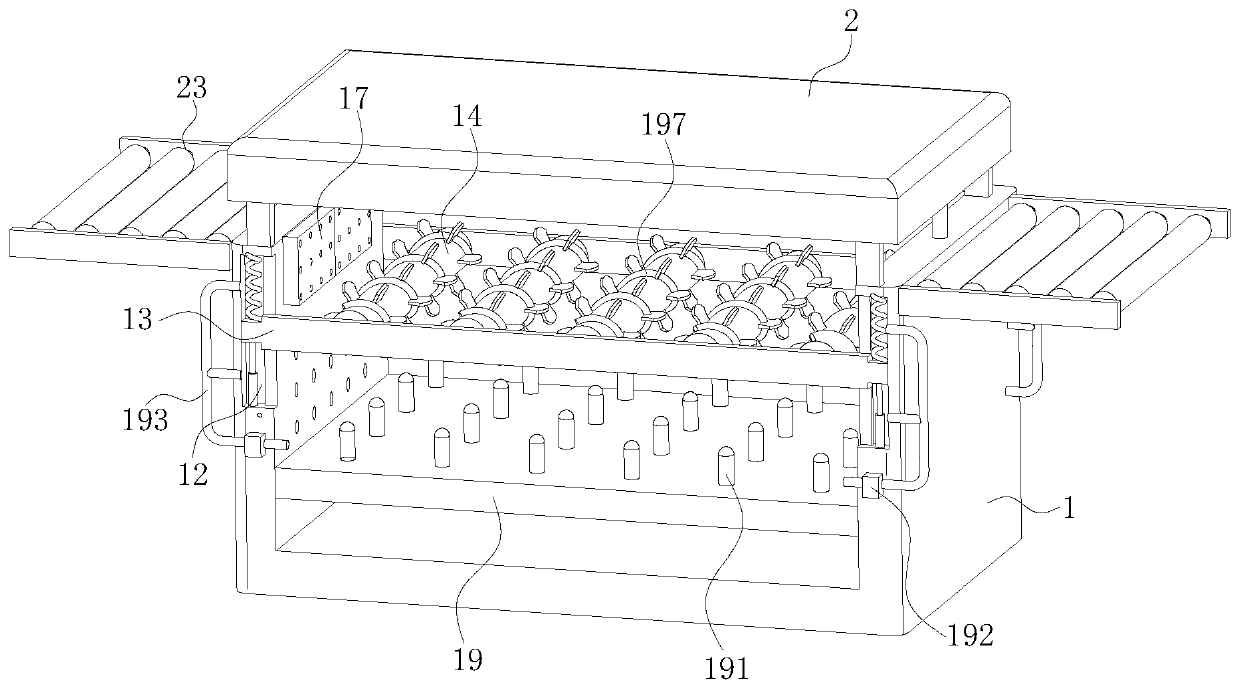

[0051] As an embodiment of the present invention, uniformly arranged water pumps 192 are fixedly connected to the inner wall of the electroplating box 1; first conduits 193 are installed in each of the water pumps 192, and the first conduits 193 extend to the uniformly arranged in the chute 12; each side plate 13 inner wall is provided with a liquid tank 194, and the liquid tank 194 is connected with the chute 12; each of the drive rod 14 inner wall is provided with a circular groove 195, and The circular grooves 195 are all in communication with the liquid groove 194; the inner wall of each circular groove 195 is provided with uniformly arranged liquid passages 196, and the liquid passages 196 all extend to the inner wall of the rotor blade 15;

[0052] During operation, during the working process of the electroplating box 1, the water pump 192 can draw the electroplating solution into the chute 12 through the first conduit 193. Since the chute 12 communicates with the liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com