Hydrogen chloride preparation process and system

A preparation system, a technology for hydrogen chloride, applied in the preparation of hydrogen chloride, chlorine/hydrogen chloride, electrodes, etc., can solve problems such as changing the position of electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

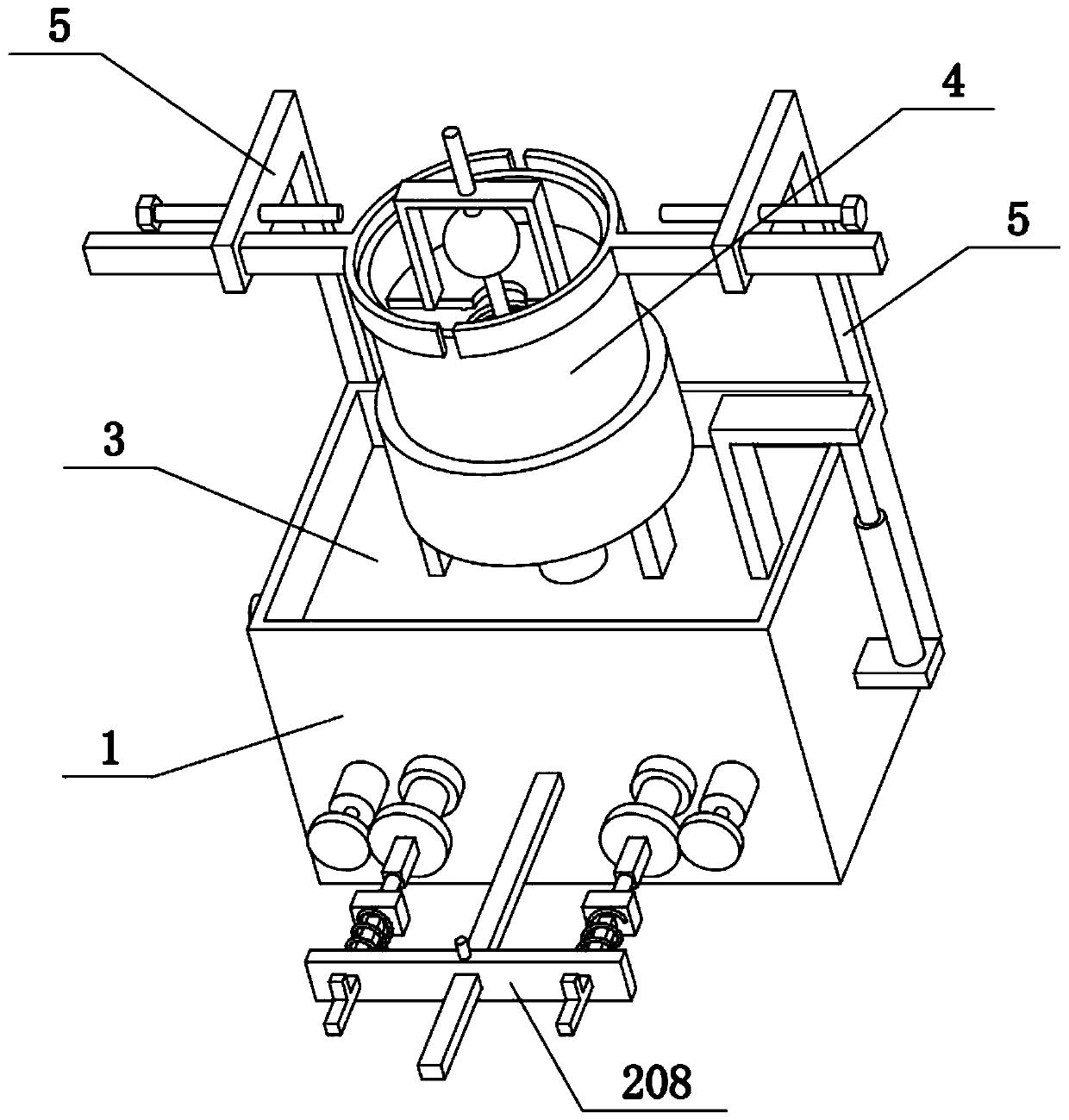

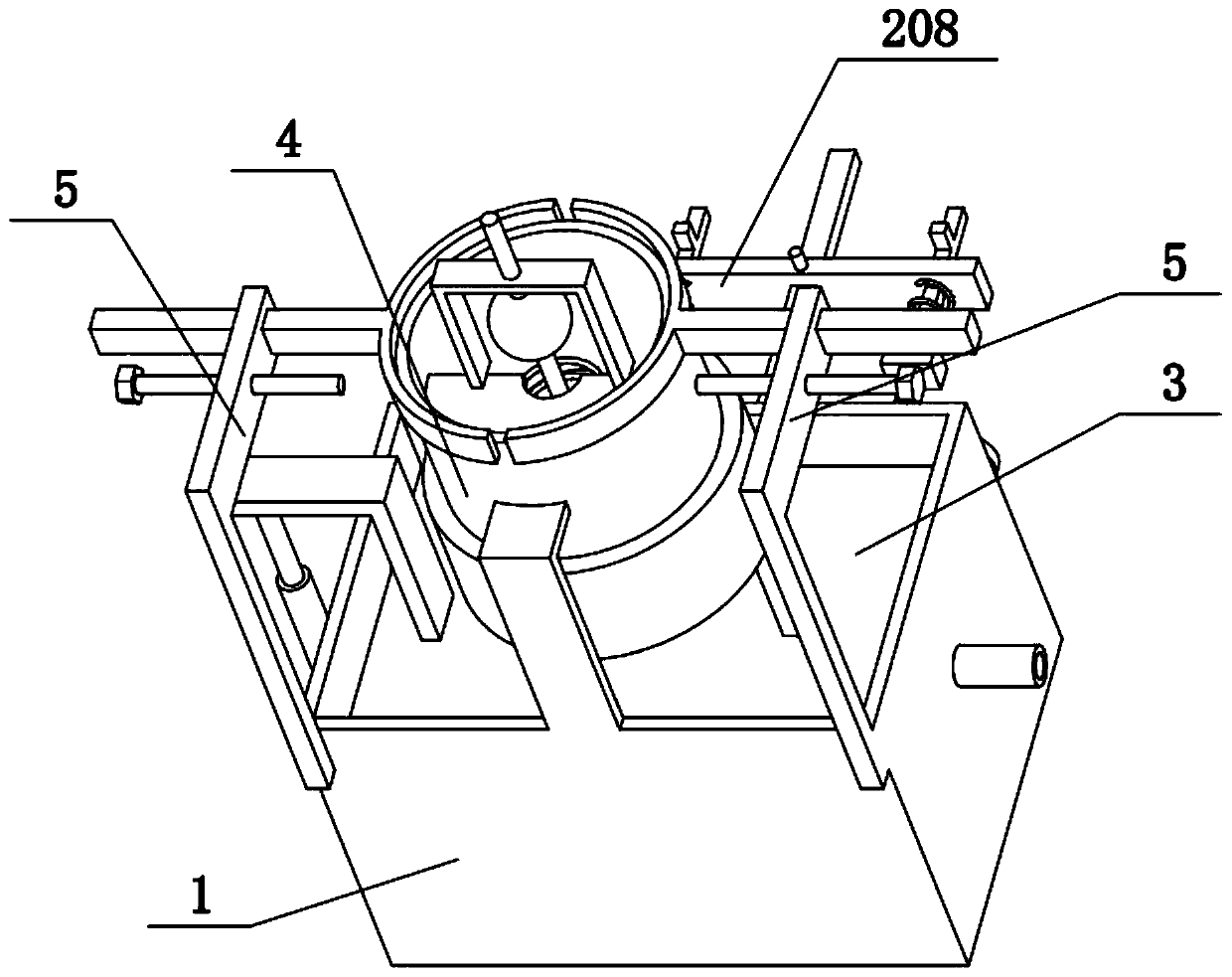

[0031] Combine below Figure 1-8 To illustrate this embodiment, the present invention relates to the field of hydrogen chloride preparation, more specifically a hydrogen chloride preparation system, including a reaction box 1, a feed pipe 101, an L-shaped plastic column 2, a limit ring 201, a rotating drum 202 and a metal column 204. Change the position of the electrodes during the electrolysis process to fully electrolyze the raw materials.

[0032] The left and right sides of the L-shaped plastic columns 2 are respectively provided with one, the rear parts of the two L-shaped plastic columns 2 are rectangular, and the middle parts of the two L-shaped plastic columns 2 are provided with a drum 202, and the two drums 202 are respectively Rotationally connected to the left and right ends of the front side of the reaction box 1, two stop rings 201 are fixedly connected to the two rotating drums 202, and the two stop rings 201 on the same rotating drum 202 are respectively connec...

specific Embodiment approach 2

[0034] Combine below Figure 1-8To illustrate this embodiment, the hydrogen chloride preparation system also includes a gear 105, a motor 106 and a gear ring 203, and the left and right ends of the front side of the reaction box 1 are fixedly connected with motors 106, and the output shafts of the two motors 106 are fixedly connected with The gear 105 and the front parts of the two drums 202 are fixedly connected with the gear rings 203 , and the two gears 105 are meshed with the two gear rings 203 respectively for transmission. Two motors 106 respectively drive two gears 105 to rotate, and then drive two gear rings 203 to rotate, and two gear rings 203 to rotate respectively drive two drums 202 and two L-shaped plastic columns 2 to rotate, and then in the process of electrolysis Change the electrode position to fully electrolyze the raw materials, and also stir the sodium chloride and aqueous solution for better electrolysis.

specific Embodiment approach 3

[0036] Combine below Figure 1-8 To illustrate this embodiment, the hydrogen chloride preparation system also includes a front track rod 104, a contact block 205, a retaining column 206, a terminal post 207, a horizontal bar 208 and a fastening screw 209, and the front middle part of the reaction box 1 is fixedly connected with a front track Rod 104, horizontal bar 208 is slidably connected on the front rail bar 104, and the horizontal bar 208 is threadedly connected with fastening screw 209, and the fastening screw 209 is supported on the front track bar 104, and the left and right ends of the horizontal bar 208 are all in front and rear. There are binding posts 207 slidingly connected in the direction, the rear ends of the two binding posts 207 are fixedly connected with the contact block 205, the front ends of the two binding posts 207 are fixedly connected with the stop post 206, and the two stop posts 206 are all located on the bar 208 The front side of the two terminal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com