Dissimilar plate butt welding electromagnetic quantitative stirring device

A stirring device and electromagnetic stirring technology, which are applied in welding equipment, non-electric welding equipment, welding/welding/cutting items, etc., can solve the problem that it is difficult to meet the welding quality requirements of dissimilar metal materials, and the mechanical properties of the joint fusion zone and heat-affected zone are poor. , the decline of mechanical properties of joints, etc., to achieve the effect of promoting mechanical and thermal effects, excellent joint performance, and improving butt welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

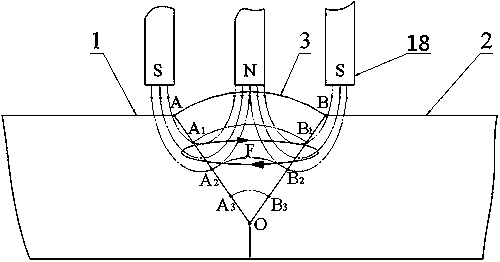

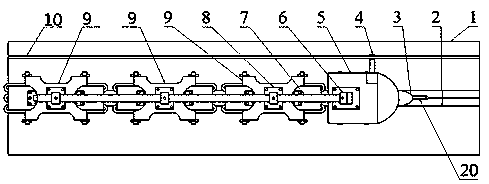

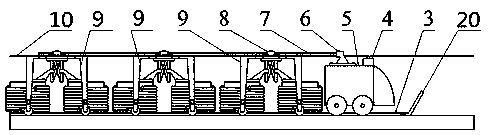

[0035]An electromagnetic quantitative stirring device for butt welding of dissimilar plates. Before welding, plate A1 and plate B2 are processed with Y-shaped grooves, which are installed on the welding tool during welding. The welding adopts four-wire submerged arc welding, and the welding speed is 400mm / min. The outer surface of the molten pool 3 is rapidly solidified under the action of welding slag or protective gas, which greatly avoids the oxidation of the molten metal during the stirring process, and the magnetic navigation sensor 4 guides the traction trolley 5 to move forward along the molten pool 3 , the speed of the traction trolley 5 is consistent with the welding speed, the weld metal is different from the base metal, the distance between the traction trolley 5 and the welding wire 22 is 5mm, and the length of the traction trolley 5 is 55mm. The electromagnetic stirring device 9 is provided with 3 pieces, and the connector A6 arranged in the middle of the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com