A kind of water glass old sand regeneration method

A technology for recycling old sand and water glass, which is applied in casting molding equipment, metal processing equipment, manufacturing tools, etc. It can solve the problems of insufficient cleaning force of the adhesive film, failure to achieve regeneration effect, and unsatisfactory regeneration effect. Low cost, good effect, and the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

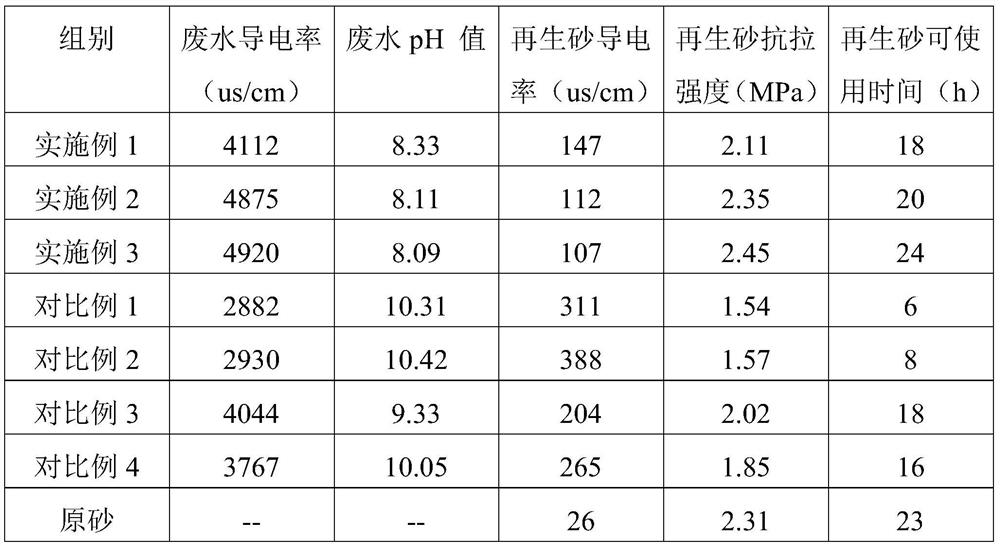

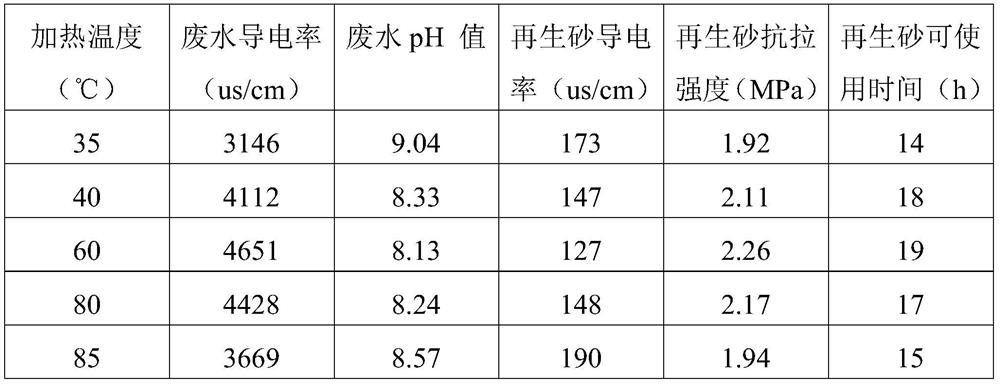

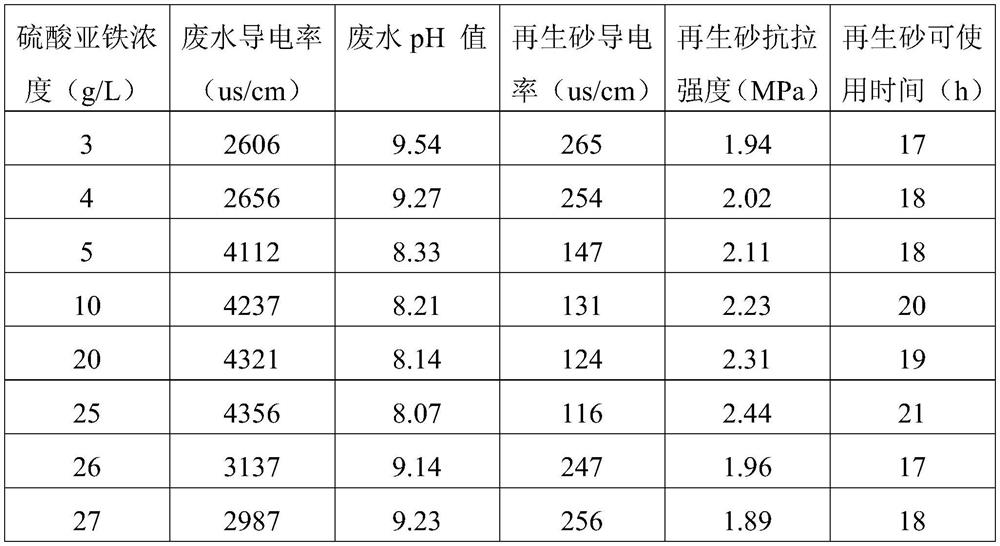

Embodiment 1

[0032] The water glass old sand regeneration method of the present embodiment may further comprise the steps:

[0033] (1) The old sand of water glass is pulverized, and the old sand of water glass after pulverization is passed through a 20-mesh sieve. The particle diameter of the old water glass sand is less than 0.6mm. Add ferrous sulfate aqueous solution, and the concentration of ferrous sulfate aqueous solution is 5g / L , the volume ratio of the old water glass sand to the ferrous sulfate aqueous solution is 1:0.8, stir evenly in the centrifugal stirring drum, the bottom of the centrifugal stirring drum is provided with an ultrasonic emission rod, a centrifugal stirring motor and an electric heating device, and the The ultrasonic emitting rod, the centrifugal stirring motor and the electric heating device are all turned on, the frequency of the ultrasonic emitting rod is 35kHz, and the distribution frequency is 300cm 2 / piece, the rotational speed of the centrifugal stirri...

Embodiment 2

[0036] The water glass old sand regeneration method of the present embodiment may further comprise the steps:

[0037] (1) the old sand of water glass is pulverized, and the old sand of water glass after pulverizing is crossed 30 mesh sieves, and the particle diameter of the old sand of water glass is less than 0.6mm, adds ferrous sulfate aqueous solution, and the concentration of ferrous sulfate aqueous solution is 12.5g / L, the volume ratio of sodium silicate old sand and ferrous sulfate aqueous solution is 1:1, stirs evenly in the centrifugal stirring drum, and the bottom of described centrifugal stirring drum is provided with ultrasonic emission rod, centrifugal stirring motor and electric heating device, Turn on the ultrasonic emitting rod, centrifugal stirring motor and electric heating device, the frequency of the ultrasonic emitting rod is 40kHz, and the distribution frequency is 315cm 2 / piece, the rotational speed of the centrifugal stirring motor is 230r / min, the t...

Embodiment 3

[0040] The water glass old sand regeneration method of the present embodiment may further comprise the steps:

[0041](1) The old sand of water glass is pulverized, and the old sand of water glass after pulverization is passed through a 40-mesh sieve, and the particle diameter of the old water glass sand is less than 0.6mm. Add ferrous sulfate aqueous solution, and the concentration of ferrous sulfate aqueous solution is 20g / L The volume ratio of the old water glass sand to the ferrous sulfate aqueous solution is 1:1.2, and it is evenly stirred in the centrifugal stirring drum, and the bottom of the centrifugal stirring drum is provided with an ultrasonic emitting rod, a centrifugal stirring motor and an electric heating device, and the The ultrasonic emitting rod, the centrifugal stirring motor and the electric heating device are all turned on, the frequency of the ultrasonic emitting rod is 45kHz, and the distribution frequency is 330cm 2 / piece, the rotational speed of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com