Batching structure of quantitative proportioning type feed stirrer for livestock raising

A mixer and feed technology, which is applied to mixer accessories, feed, applications, etc., can solve the problems of inaccurate feed amount, reduced processing effect, and large gap in feed ratio, so as to achieve improved effect, uniform feeding amount, and feeding The effect of speed stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

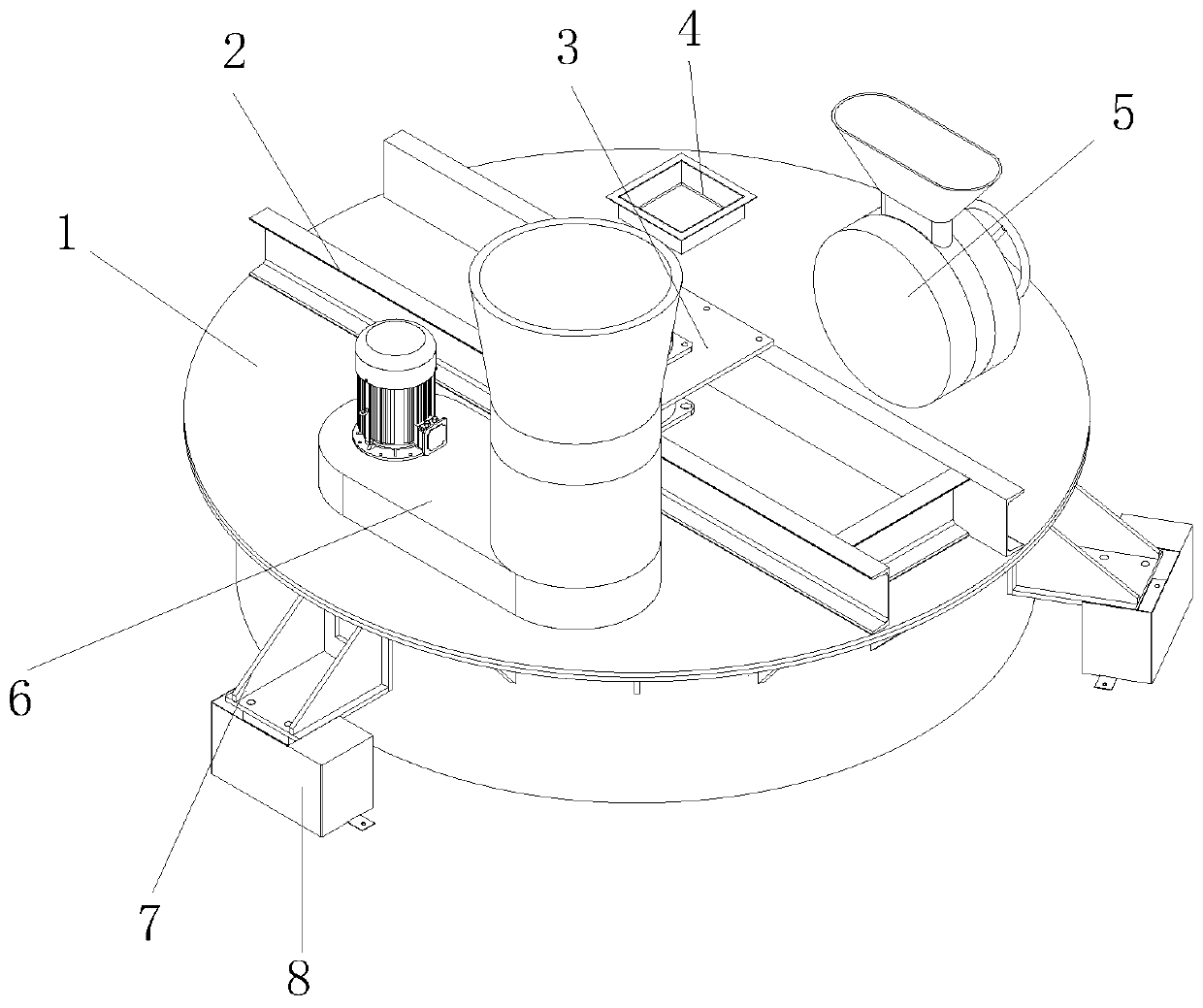

[0033] see figure 1 , the present invention provides a batching structure of a quantitative proportioning type feed mixer for animal husbandry through improvement, including a top cover 1, a fixing frame 2 welded to the top middle of the top cover 1, and a fixing frame 2 connected to a connecting seat 3 by bolts in the middle of the top end. Fixed, the top left rear end of the top cover 1 is welded with an injection bucket 4, the bottom of the top cover 1 near the edge is welded with a support frame 7 at the four ends, the bottom of the support frame 7 is fixed with the support 8 by bolts, and the top right rear end of the top cover 1 A stable feeding device 5 is provided, and the middle part of the top end of the top cover 1 is connected with the quantitative device 6 .

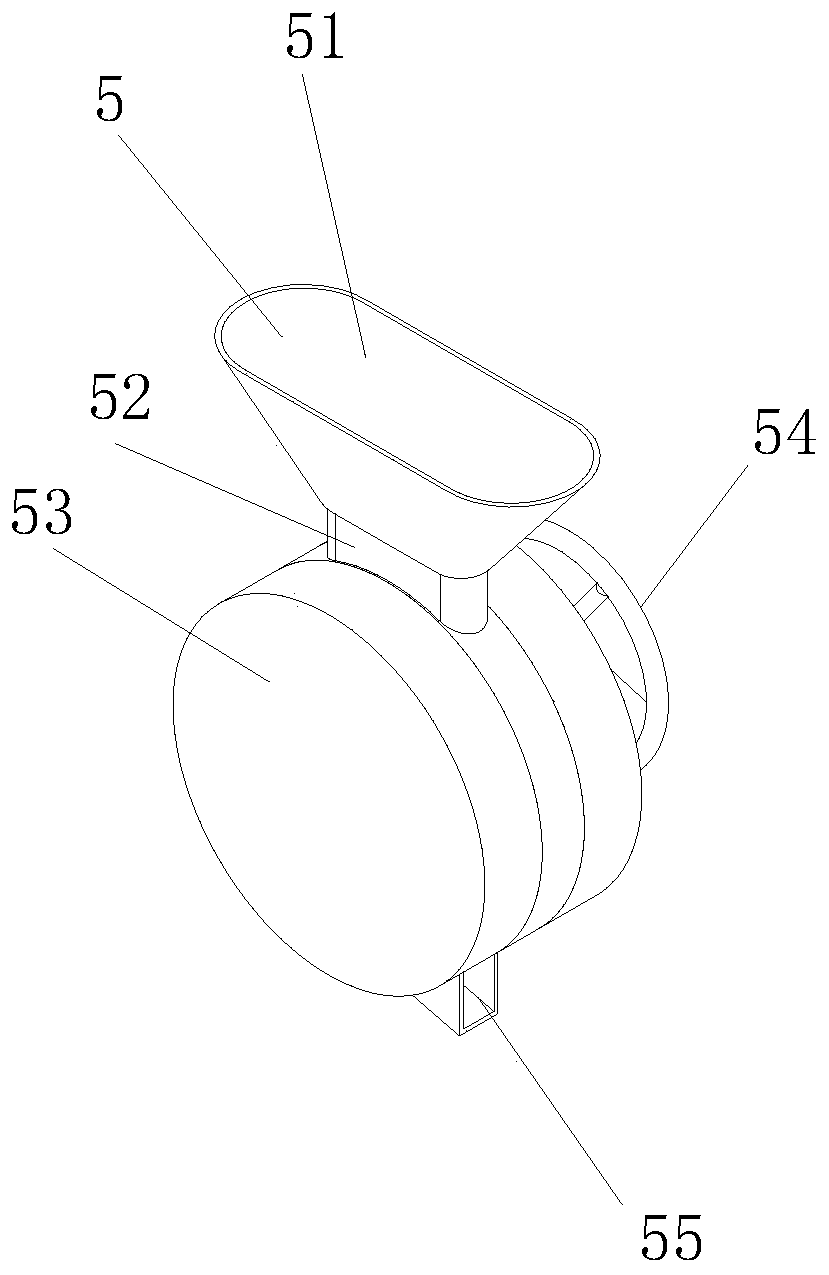

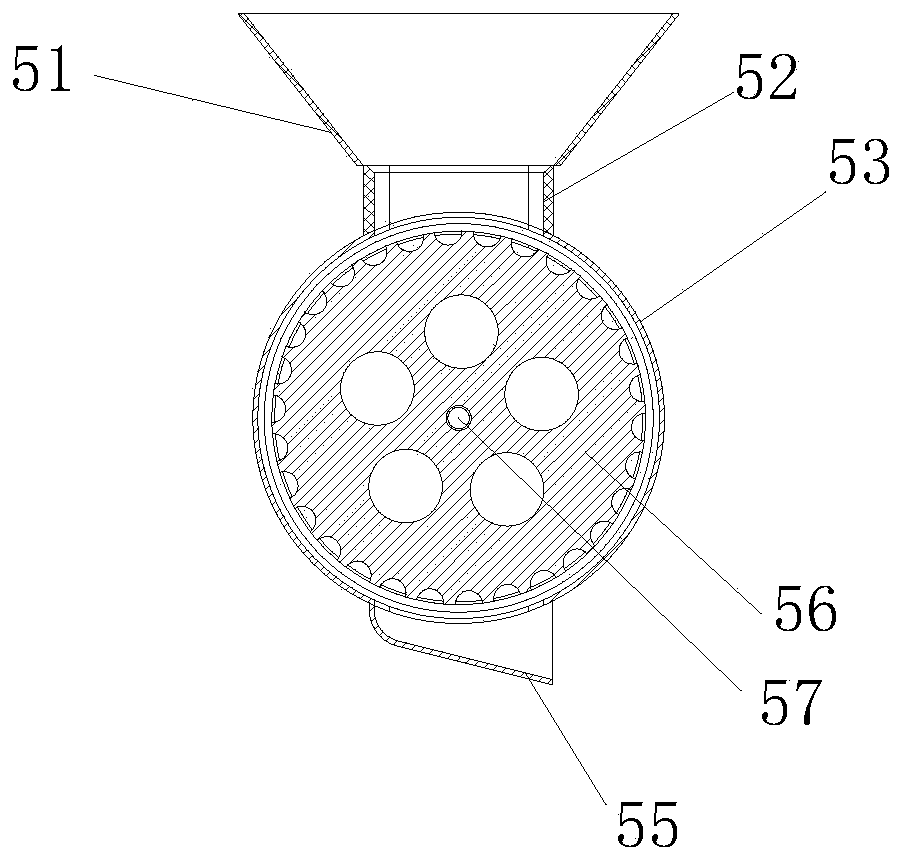

[0034] see figure 2 and image 3 , the present invention provides a batching structure of a quantitative proportioning type feed mixer for animal husbandry through improvement. The stable feeding device 5...

Embodiment 2

[0040] The present invention provides a batching structure of a quantitative proportioning type feed mixer for animal husbandry through improvement. Both ends of the fixed shell 53 are fixed with circular plates, and the gear 56 is placed in the middle of the fixed shell 53, and the circular plate is used for protection. Make it difficult to be affected during the blanking process; the insertion rod 67 is placed at the lower end of the fixed disk 62, and the insertion rod 67 is idling during the rotation process, the fixed disk 62 is in a fixed state, and the rotating cylinder 63 rotates as an effective feed blanking; the blocking block The surface of 612 is smooth, and the top of the blocking block 612 is inclined to the right, which is more convenient for the feed to fall.

[0041] The present invention provides a batching structure of a quantitative proportioning type feed mixer for animal husbandry through improvement, and its working principle is as follows;

[0042] Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com