A magnetic field modulation hybrid excitation motor and its multi-operating wave design method

A hybrid excitation motor and magnetic field modulation technology, which is applied in the field of rail transit and electric vehicles, to achieve the effects of reducing the reluctance of the excitation magnetic field, enhancing the magnetic field adjustment energy, and reducing the length of the end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

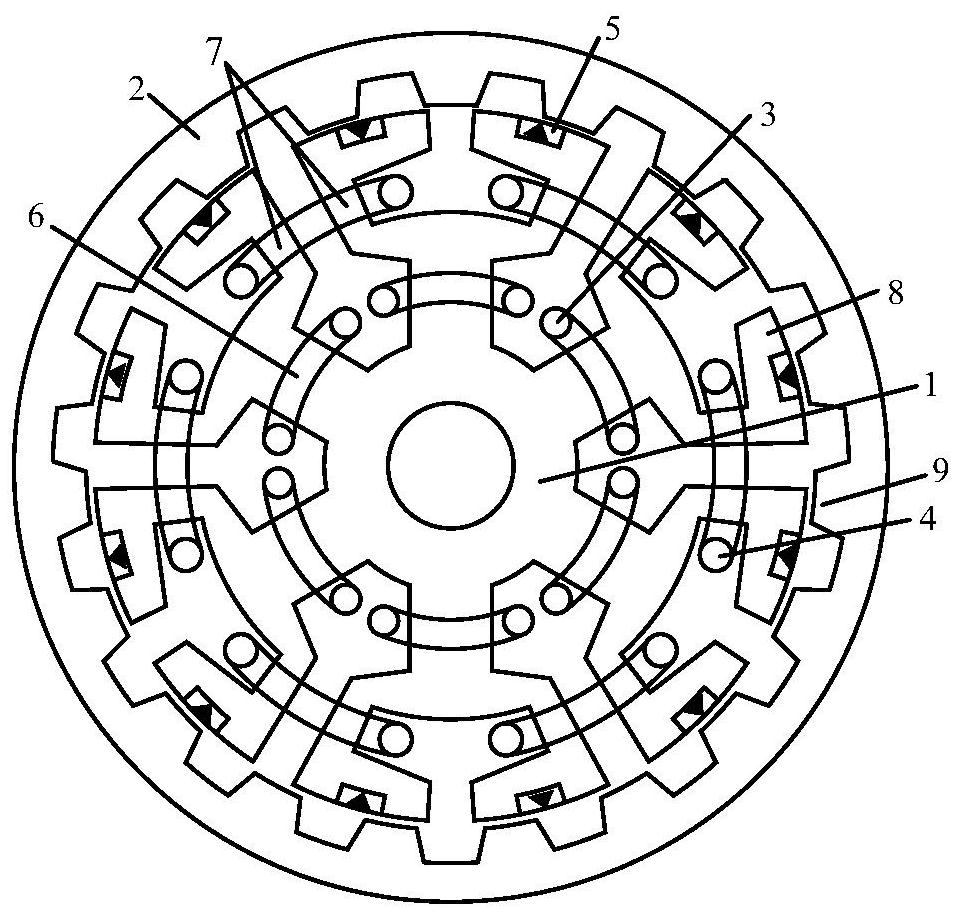

[0084] figure 1 It is a structural schematic diagram of a hybrid excitation motor according to an embodiment of the present invention. Such as figure 1 As shown, the motor is a three-phase motor, including a stator (1) and a rotor (2), which are installed coaxially, and the stator (1) is sleeved in the rotor. The material of the stator core is the same as that of the rotor (2), which is formed by laminating silicon steel sheets. There is a groove on the surface of each stator tooth (6), which splits the end of the stator tooth (6) into two modulation teeth (7), and the excitation winding (4) is placed in the groove of the stator tooth, and the excitation adopts double-layer centralized Wound on two adjacent modulated teeth (7) split by different stator teeth (6), the armature winding (3) is placed in the open slot of the stator core, and is wound on the stator teeth ( 6) on. Among them, the excitation winding (4) is supplied with direct current, and the direction of the cu...

example 2

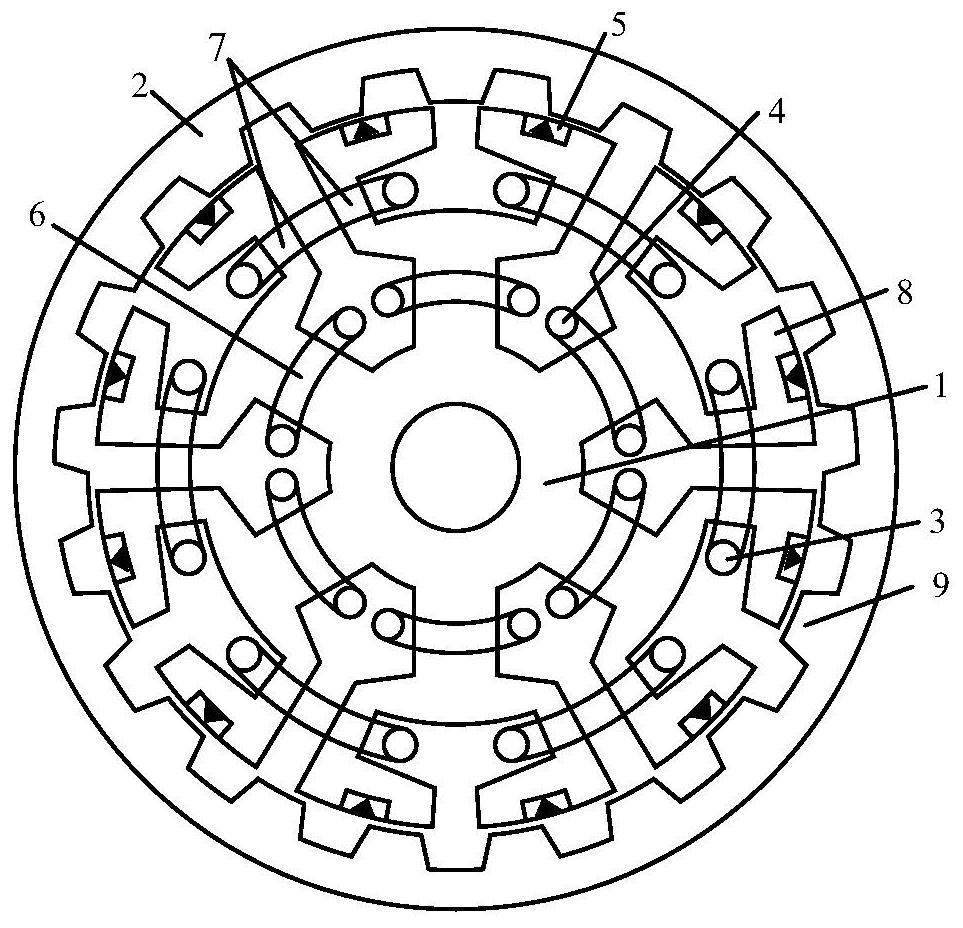

[0094] In another embodiment of the present invention such as figure 2 As shown, compared with this embodiment, the structure of the motor stator and rotor is exactly the same, but the installation positions of the armature winding (3), the field winding (4) and the permanent magnet (5) are different. In another embodiment, the armature The winding (3) is placed in the groove of the stator teeth, and the double-layer concentrated winding is on two adjacent modulation teeth split by different stator teeth; the excitation winding (4) is placed in the open slot of the stator core, The double-layer centralized winding is on a stator tooth (6); the magnetization direction of the permanent magnet (5) is radial magnetization, and the placement position is: two modulation teeth ( The polarities of the permanent magnets (5) on 7) are the same, and the polarities of the permanent magnets (5) on two adjacent modulating teeth (7) split by different stator teeth (6) are opposite.

[0095...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com