A mems probe single-axis symmetric bending test structure and its pitch arm

A symmetrical bending and testing structure technology, applied in the direction of testing material strength by applying stable bending force, testing material strength by applying stable tension/pressure, measuring devices, etc., can solve the difficult problem of heat dissipation, and no palladium alloy probe has been found. Needle test equipment, technical difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0103] The following is a specific embodiment of the MEMS palladium alloy probe testing device of the present invention.

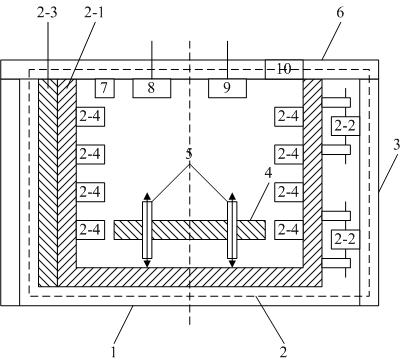

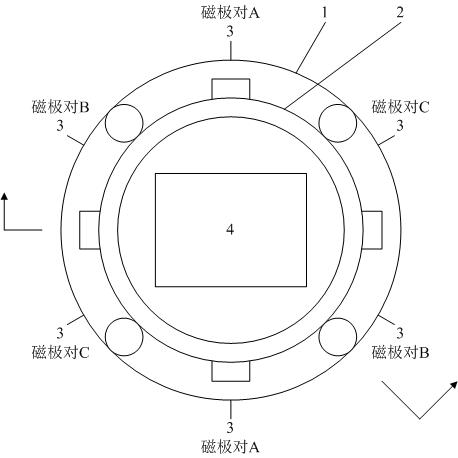

[0104] The MEMS palladium alloy probe testing device under the present embodiment, the structure schematic diagram is as follows figure 1 shown. The MEMS palladium alloy probe testing device comprises a barrel-shaped housing 1, a disturbance structure 2 arranged on the inner wall of the barrel-shaped housing 1, an electromagnetic pole 3 arranged on the outer wall of the barrel-shaped housing 1, and arranged horizontally in the barrel-shaped housing 1 Placed reference test platform 4, a symmetrical bending test structure 5 positioned above the reference test platform 4, a sealing cover 6 arranged above the barrel-shaped housing 1 and a sensor 7 installed on the sealing cover 6, a sprayer 8, a heater 9 and fan 10;

[0105] The disturbance structure 2 includes a disturbance body 2-1 with a circular cross section, a roller 2-2 and a tooth structure 2-3 dispo...

specific Embodiment approach 2

[0112] The following is a specific embodiment of the MEMS palladium alloy probe testing device of the present invention.

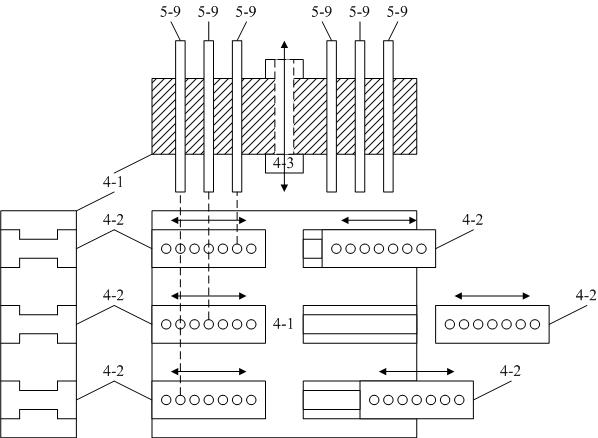

[0113] The MEMS palladium alloy probe test device under the present embodiment, on the basis of the specific embodiment one, further defines that the benchmark test platform includes a main board 4-1 and a plurality of sliders 4-2, and the main board 4-1 is provided with There are gaps from both sides to the center of symmetry, the cross-sectional shape of the gap is "I" shape, a slider 4-2 is inserted in the gap, and a plurality of vertical shafts are equally spaced on the slider 4-2 A circular through hole in a straight direction, the through hole can be equipped with a lifting structure 5-9, such as image 3 Shown; The material of described main board 4-1 and slide block 4-2 is different, specifically as follows:

[0114] First, the speed at which the volume of the material of the main board 4-1 increases with the increase of temperature is lower than ...

specific Embodiment approach 3

[0120] The following is a specific implementation of the benchmark test platform in the MEMS palladium alloy probe test device of the present invention.

[0121] The benchmark test platform under the present embodiment includes a main board 4-1 and a plurality of sliders 4-2, the main board 4-1 is provided with a gap from both sides to the symmetrical center direction, and the cross-sectional shape of the gap is "I" shape, a slider 4-2 is inserted in the gap, and a plurality of circular through holes in the vertical direction are equally spaced on the slider 4-2, and the through holes can be installed with a lifting structure 5- 9, such as image 3 Shown; The material of described main board 4-1 and slide block 4-2 is different, specifically as follows:

[0122] First, the speed at which the volume of the material of the main board 4-1 increases with the increase of temperature is lower than that of the material of the slider 4-2 with the increase of temperature. Before testi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com