Temperature rise control method for inclined surface oil pads of static pressure circular guide rail

A control method and technology of circular guide rails, which are used in liquid cushion bearings, manufacturing tools, large fixed members, etc., can solve problems affecting the machining accuracy of parts and lubrication failures, avoid lubrication failures, and improve machining performance and operation accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] now combined with Figure 1-3 The present invention is described in further detail.

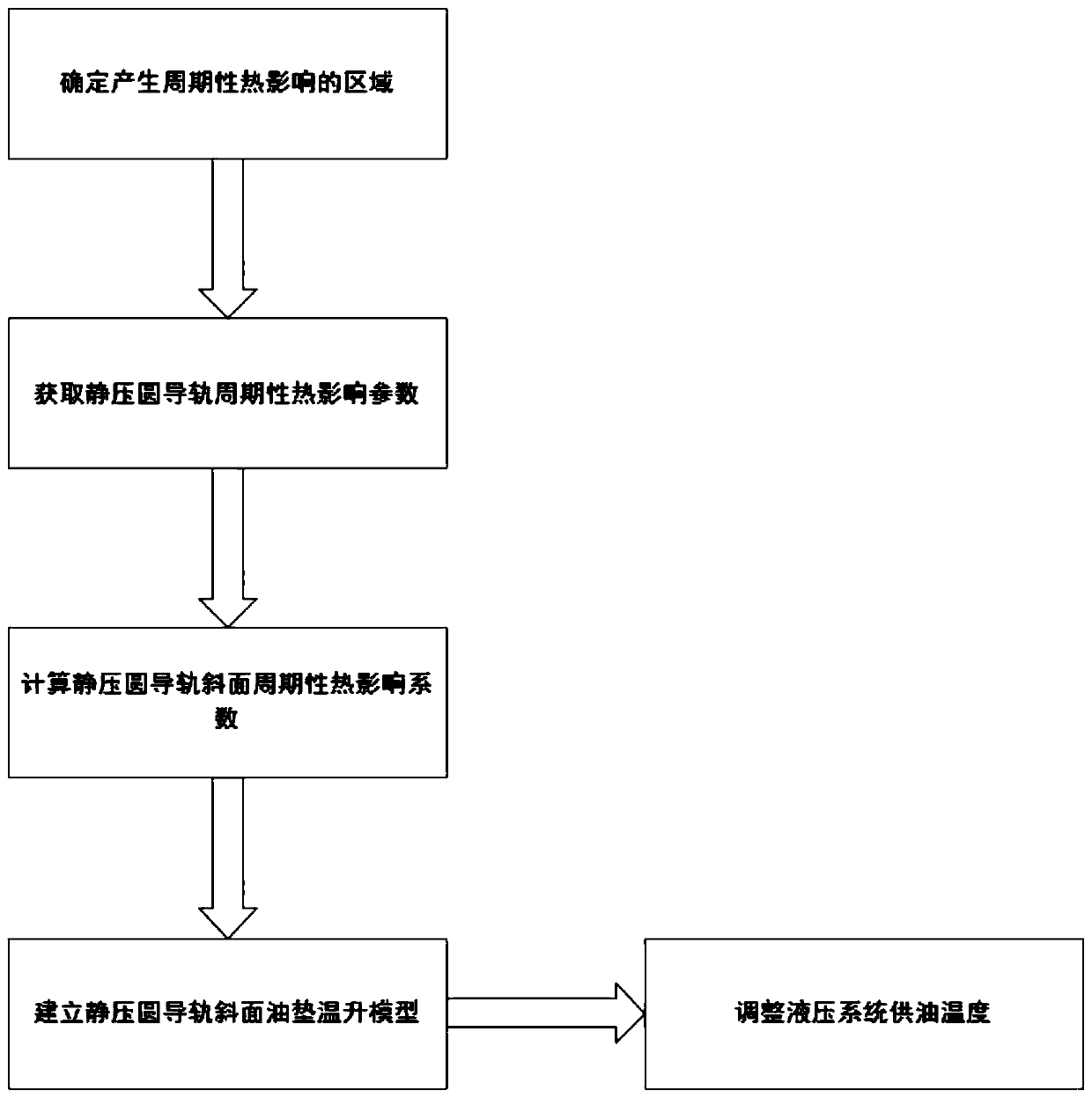

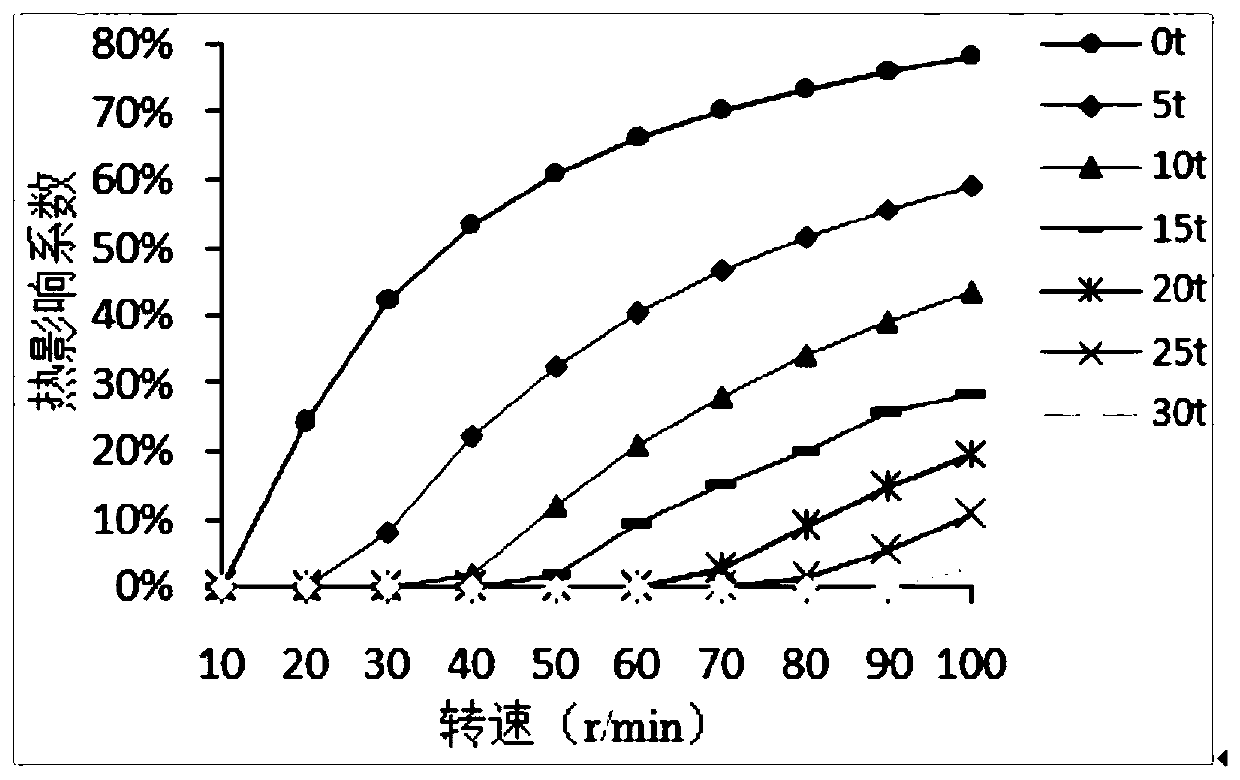

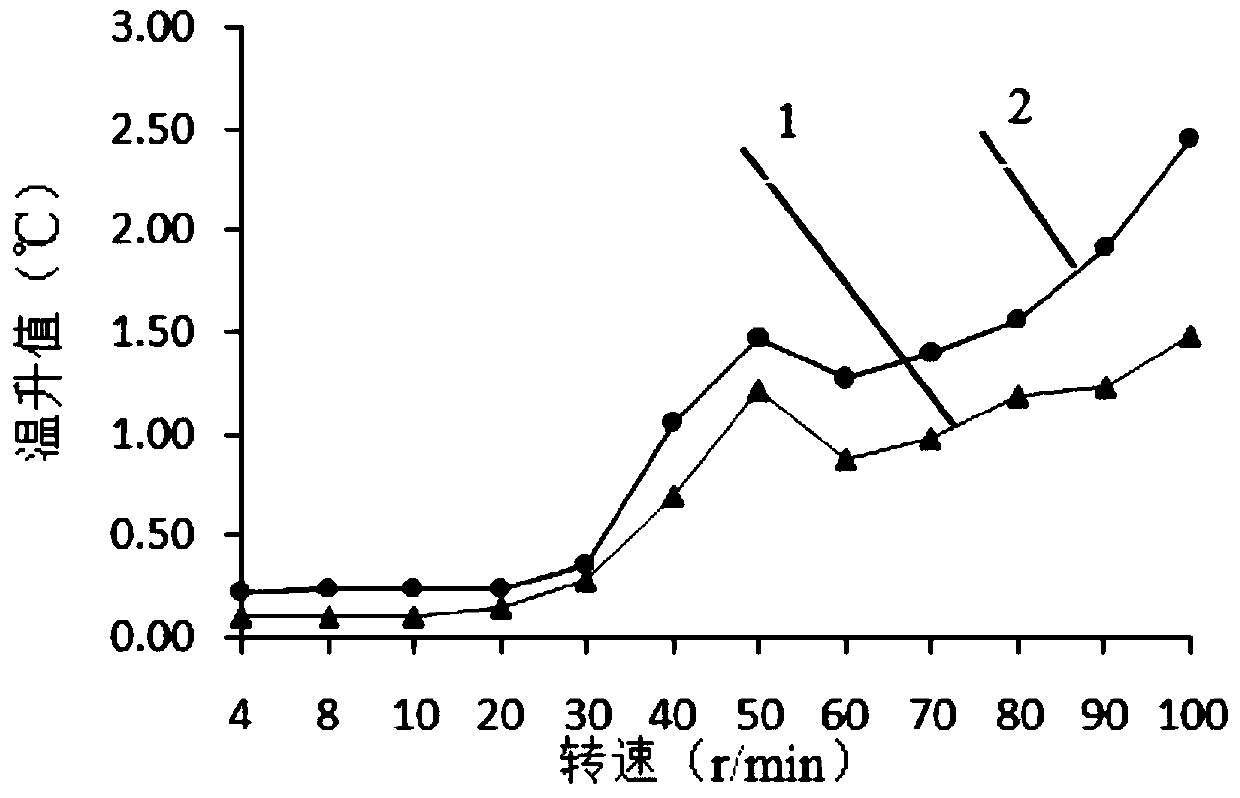

[0029] Such as figure 1 As shown, in one of the embodiments of the present invention, the method for controlling the temperature rise of the inclined plane oil pad of the static pressure circular guide rail determines the periodical thermal influence by analyzing the periodic flow mechanism of the oil film in the gap between the adjacent oil pads on the static pressure circular guide rail. For the problem area, according to the operating characteristics of the turntable, the left and right sides of the circumference of a single oil pad are the key research areas. The film thickness on the left side is greater than that on the right side. When the turntable rotates clockwise, the faster the turntable rotates, the thermal influence between adjacent oil pads more serious. According to the flow mechanism of the static pressure circular guide rail, since the flow is the carrier of the hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com