Gas-solid mixed rocket engine free of initiating explosive device

A rocket engine, gas-solid mixing technology, applied in rocket engine devices, machines/engines, mechanical equipment, etc., can solve problems such as personal damage, failure to consider the safety hazards of solid gunpowder, complex engine structure during operation, etc., to improve the space. Effectiveness of utilization and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

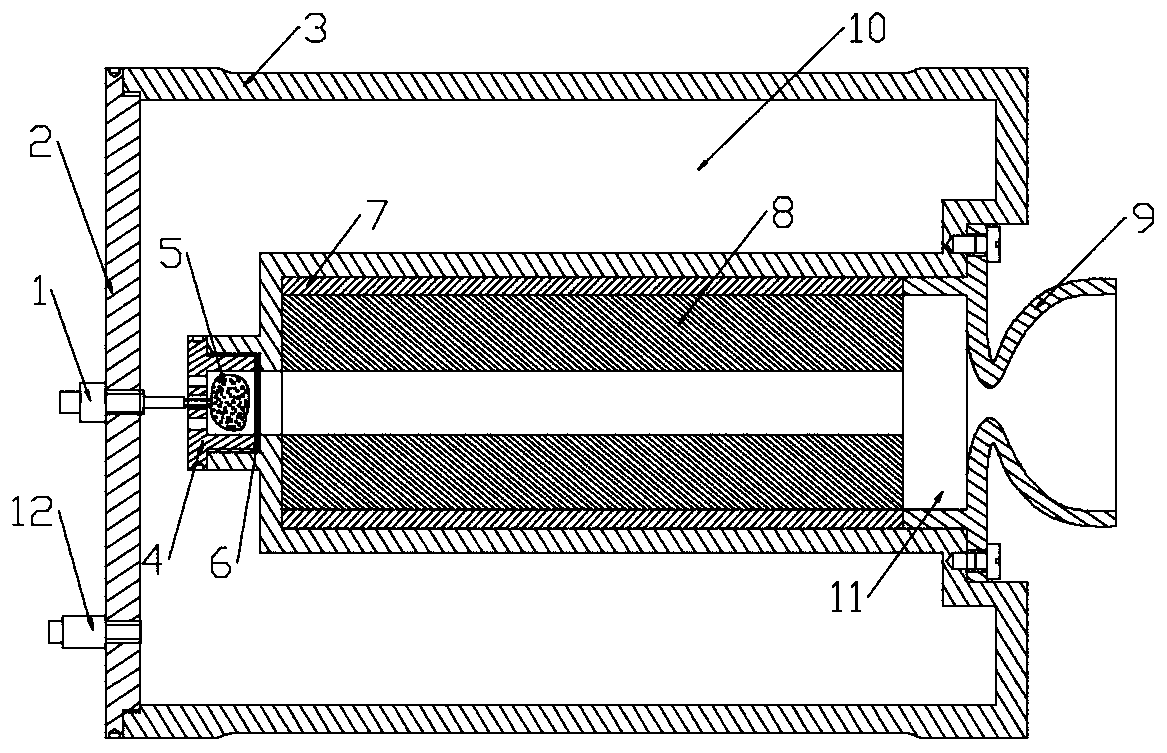

[0024] This embodiment is a gas-solid hybrid rocket motor without explosives.

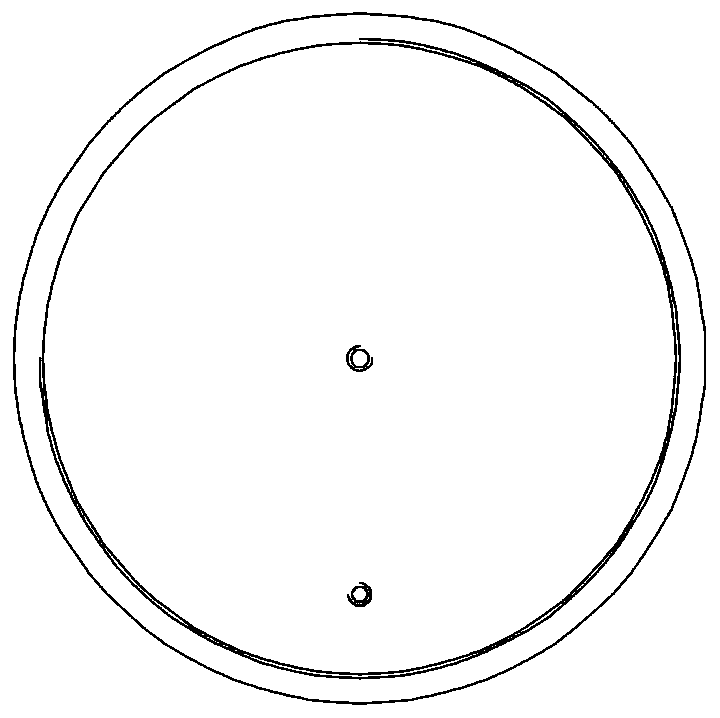

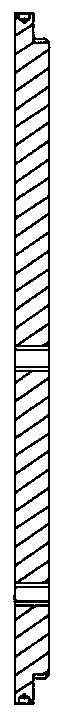

[0025] refer to Figure 1 to Figure 9 , the gas-solid hybrid rocket engine without pyrotechnics in this embodiment consists of a spark plug 1, a top cover 2, an engine casing 3, an injector 4, carbon powder 5, a bursting disc 6, an insulating layer 7, a solid propellant 8, a spray Tube 9, high-pressure air chamber 10, combustion chamber 11 and check valve 12; wherein, engine casing 3 is two concentric cylinder structures that are connected by a step surface at one end, and at the front end of the inner cylinder A hollow boss is provided, the inner wall of the boss is threaded in the circumferential direction, the injector 4 is threadedly connected with the boss of the inner cylinder of the engine casing 3, and the bursting disc 6 is located on the boss of the inner cylinder of the engine casing 3 and is injected In the groove formed between the injectors 4, the carbon powder 5 is placed in the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com