A kind of fast burning biomass fuel manufacturing equipment

A technology of biomass fuel and manufacturing equipment, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the troublesome production process, increase the cost of biofuel production, etc., and achieve the effect of increasing ethanol content and accelerating combustion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of fast burning biomass fuel manufacturing equipment, comprising a reaction box 1, a heating device is installed in the reaction box 1, comprising the following steps:

[0038] S1. Mixing sawdust and bagasse according to 1:1 into the alcohol waste water and soaking for 15 minutes, then putting the sawdust and bagasse chips with the alcohol waste water into the reaction box 1;

[0039] S2. Add Bacillus pumilus culture solution and Zymomonas mobilis culture solution to the reaction box 1, the mixing ratio is 1:1.5, and the mixed culture solution is sprinkled on the surface of sawdust and bagasse debris;

[0040] S3. Add calcium bicarbonate powder into the reaction box 1, and start the heating device in the reaction box 1, so that the temperature in the reaction box 1 is controlled at 30°C.

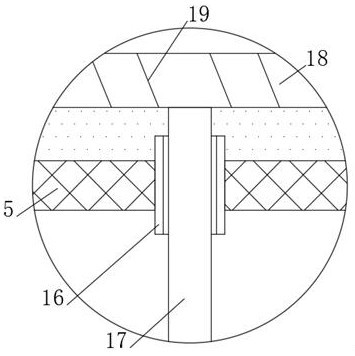

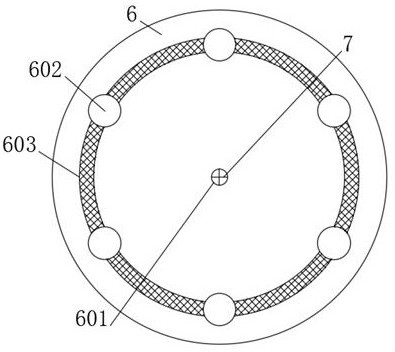

[0041] see Figure 1-6 , the inner wall of the reaction box 1 is fixedly connected with a fixed partition 2, the bottom of the fixed partition 2 is fixedly connected with a pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com