A composite soil-based material and its use in preparing green planting soil from river and lake dredging mud

A soil-based and composite technology, applied in the field of environmental waste treatment and resource utilization, can solve the problems of long-term land occupation, lack of strength, and heavy metal pollution of nitrogen and phosphorus nutrients in surrounding water bodies, and achieve cost economy, increased strength, and The effect of heavy metal stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

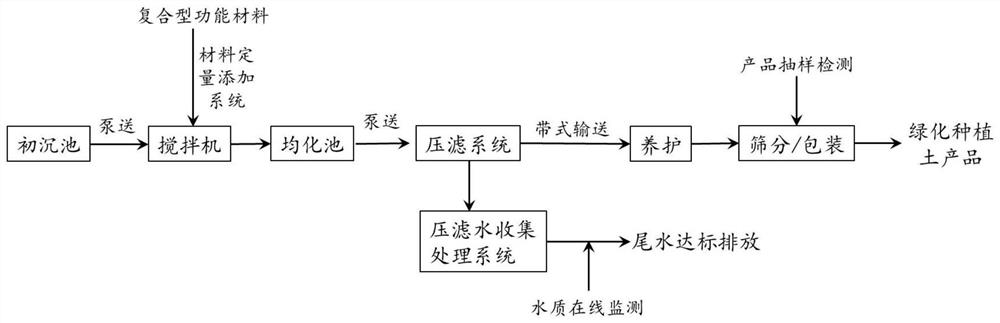

Method used

Image

Examples

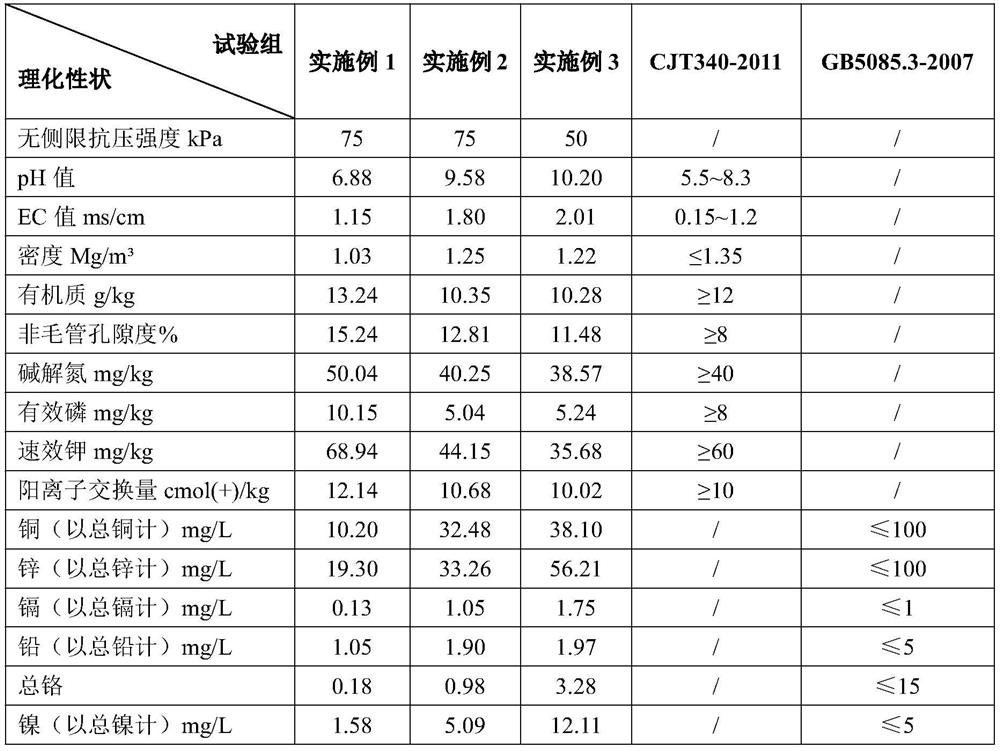

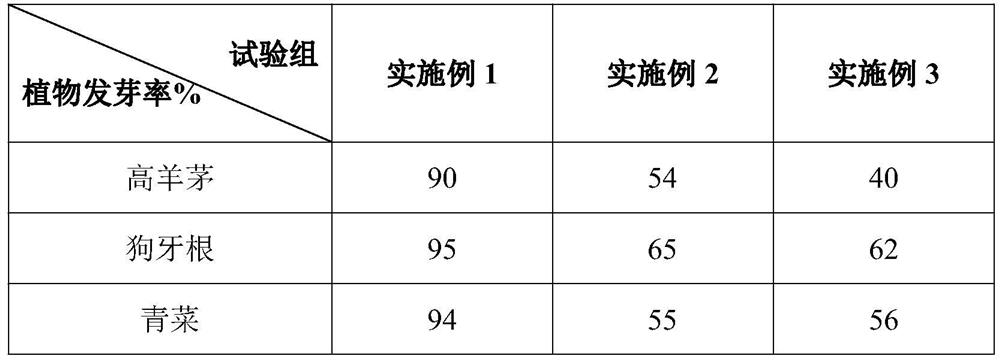

Embodiment 1

[0028]The raw material components of the composite soil material are referred to as the weight component ratio, with the main agent for cationic polyacrylamide 2.0 kg, polymers 5.0 kg, silicate cement 30.0kg, modified fly ash 35.0kg of pulverized straw; the auxiliary agent is 1.5 kg of formate, polyglutamic acid 3.0kg, activated humic acid 2.5kg.

[0029]Among them, the preparation method of modified powder coal ash and straw is as follows: Select crop straw, crush, crushing and controlling the length of 5mm in the surrounding area of corn, rice, and mixing the fly ash and pulverizing straw by mass than 1: 2, Add 1-3 wt.% Sodium hydroxide solid, then add water than 1 kg: 10 L, 10 min at 300 ° C, solid phase residual separation, washing, and dry after drying, and obtained modified fly ash and straw.

[0030]The raw materials of the agencies and the aids are given to 200 mean left and right sieves, respectively, and the auxiliary and auxiliary agents and auxiliaries are uniformly obtained...

Embodiment 2

[0033]The raw material components of the composite soil material are referred to as the weight fraction of the weight of the composite soil material, with the main agent for cationic polyacrylamide 2.0 kg, polymerized ferric chloride 5.0kg, silicate cement 30.0kg, fly ash and pulverization 35.0kg of straw (the mass ratio of fly ash and pulverized straw is 1: 2); the auxiliary agent is 1.5 kg of calcium carboxylate, polyglutamic acid 3.0kg, activated humic acid 2.5kg.

[0034]The test was selected as the Wangjia River dredging slurry as a test sample (Test Sample and Example 1 Test Sample as the same place, the same batch collection), and the dredging slurry content was 95%. The above-mentioned compound soil material main agent, the auxiliary and dredging mud are mixed into a homogenized pool than 6: 1: 50, and then pumped into a plate filter press for dehydration reduction treatment, filtration The pressure is 1.6 MPa, the pressure filter time is 15 min, and the mud cake after dehydrat...

Embodiment 3

[0037]According to the weight of the weight part ratio, the raw material components of the composite soil material, 35.0kg of silicate cement, 30.0kg, fly ash (fly ash with pulverized straw) The mass ratio of the pulverized straw is 1: 2).

[0038]The test was selected as the Wangjia River dredging slurry as a test sample (Test Sample and Example 1 Test Sample as the same place, the same batch collection), and the dredging slurry content was 95%. The composite soil material prepared above and the dredged slurry were mixed in a homogenized pool than 7:50, and then pumped into the plate frame filter machine for dehydration reduction treatment, filtering pressure 1.6MPa, pressure filter time For 15 min, the mud cake after dehydration enters the maintenance process, and the maintenance time is 14d.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com