Antibacterial latex paint and preparation method thereof

A technology of latex paint and nano antibacterial agent, applied in the field of latex paint, can solve the problems of mold growth, poor craftsmanship, blackening and peeling off the paint film, and achieve the effect of inhibiting agglomeration, wide application field and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

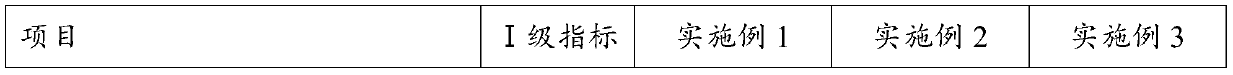

Examples

Embodiment 1

[0021] The present embodiment provides a kind of antibacterial latex paint, and described latex paint comprises the composition of following parts by weight: 100 parts of water, 9 parts of hydroxyethyl cellulose, 100 parts of modified acrylic emulsions, 27 parts of aluminum oxide modified nano titanium dioxide, ZnO w 7 parts of nano antibacterial agent, 30 parts of nano silicon dioxide, 4 parts of dispersant, 0.2 part of polydimethylsiloxane, 1 part of propylene glycol methyl ether acetate.

[0022] The modified acrylic emulsion is an organic fluorine-modified acrylic emulsion, which is specifically obtained by copolymerizing the following monomers in parts by mass: 24 parts of methyl methacrylate, 42 parts of butyl propylene, 12 parts of methacrylic acid, methacrylic acid 6 parts of hexafluorobutyl ester;

[0023] The alumina-modified nano titanium dioxide adopts TiCl 4 、Al 2 (SO 4 ) 3 As raw material, Al prepared by co-precipitation method 2 o 3 / TiO 2 nanoparticles;...

Embodiment 2

[0034] The present embodiment provides a kind of antibacterial latex paint, and described latex paint comprises the composition of following parts by weight: 100 parts of water, 8 parts of hydroxyethyl cellulose, 90 parts of modified acrylic emulsions, 30 parts of aluminum oxide modified nano titanium dioxide, ZnO w 7 parts of nano antibacterial agent, 26 parts of nano silicon dioxide, 2 parts of dispersant, 0.1 part of ethylene glycol siloxane, 1 part of propylene glycol methyl ether acetate.

[0035] The modified acrylic emulsion is an organic fluorine modified acrylic emulsion, and the specific proportioning is the same as in Example 1;

[0036] Described aluminum oxide modified nano titanium dioxide is the same as embodiment 1;

[0037] The average particle diameter of described nano silicon dioxide is 24nm;

[0038] ZnO w The nano antibacterial agent has a four-needle whisker structure;

[0039] The dispersant is a compound of sodium lauryl sulfate and 1-butyl-3-methy...

Embodiment 3

[0042] The present embodiment provides a kind of antibacterial latex paint, and described latex paint comprises the composition of following parts by weight: 100 parts of water, 12 parts of hydroxyethyl cellulose, 115 parts of modified acrylic emulsions, 38 parts of aluminum oxide modified nano titanium dioxide, ZnO w 8 parts of nano-antibacterial agent, 36 parts of nano-silica, 5 parts of dispersant, 0.3 parts of fluorosilicone, and 2 parts of diethylene glycol butyl ether.

[0043] The modified acrylic emulsion is an organic fluorine modified acrylic emulsion, and the specific proportioning is the same as in Example 1;

[0044] Described aluminum oxide modified nano titanium dioxide is the same as embodiment 1;

[0045] The average particle diameter of described nano silicon dioxide is 17nm;

[0046] ZnO w The nano antibacterial agent has a four-needle whisker structure;

[0047] The dispersant is a compound of sodium lauryl sulfate and 1-butyl-3-methylimidazolium tetraf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com