Industrial winch assembly capable of self-locking after stalling by centrifugal effect

A technology of centrifugal action and winch assembly, applied in the direction of spring mechanism, winch device, etc., can solve the problems of hoisting equipment or winch stall and falling, hidden dangers, economic losses of manufacturers, etc., to achieve safe work and construction environment, practical Good sex and safety, avoid the effect of delayed response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work shall fall within the protection scope of the present invention.

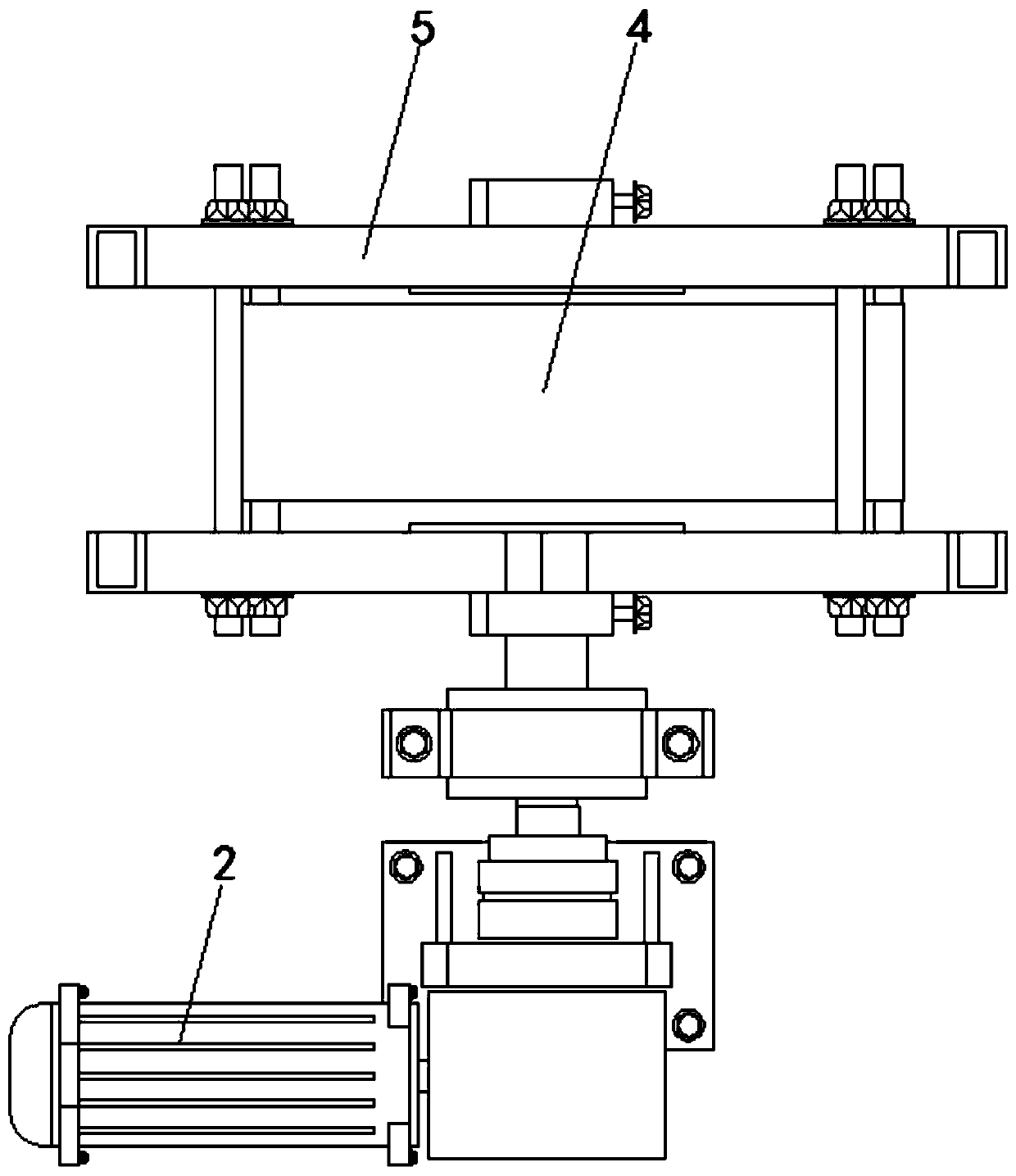

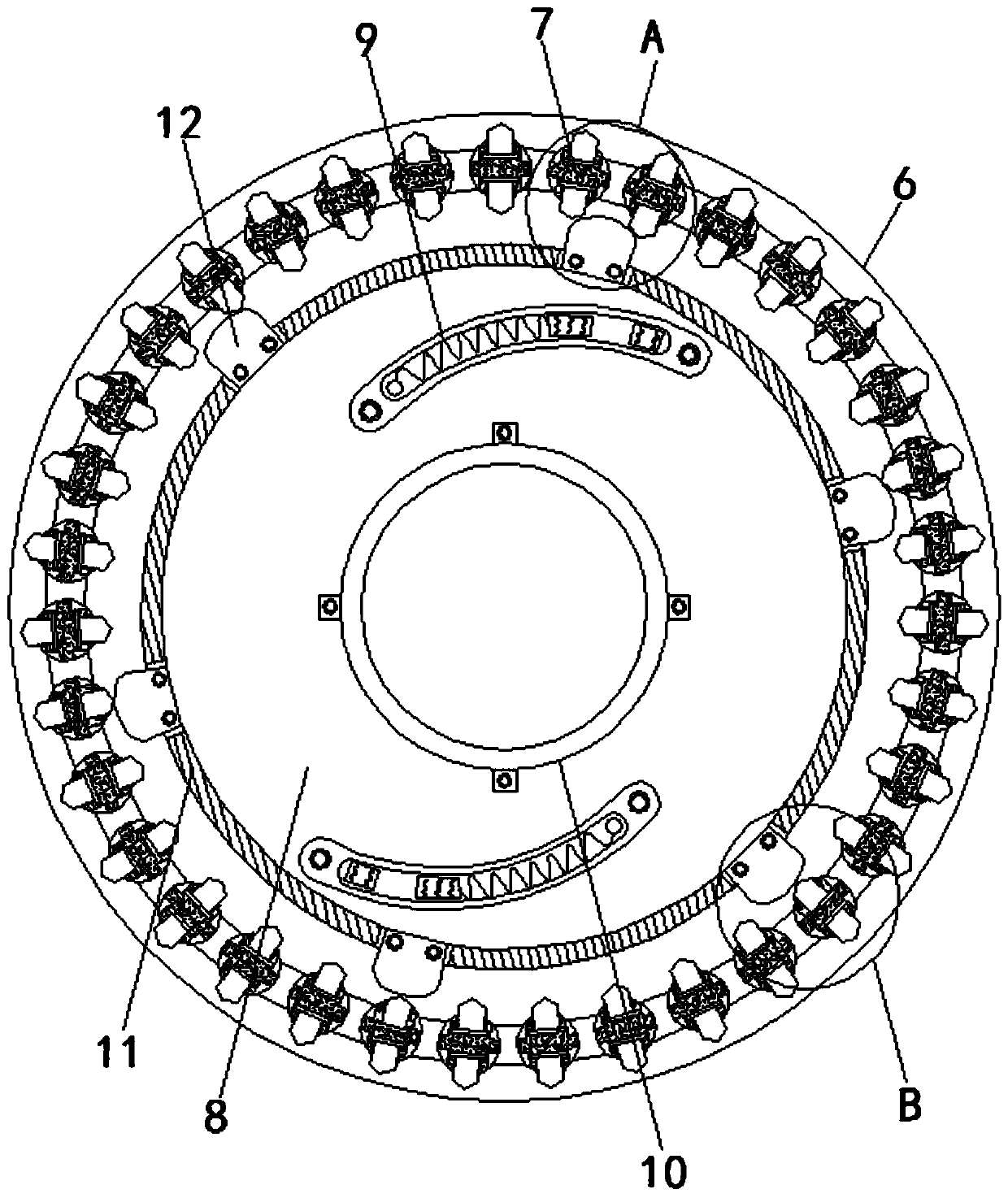

[0028] See Figure 1-9 :

[0029] The industrial winch assembly capable of stalling and self-locking by centrifugal effect includes base 1, drive motor 2, mounting plate 3, reel 4, limit rod 5, positioning plate 6, self-locking mechanism 7, limit disc 8, centrifugal mechanism 9. Winch 10, self-locking disc 11, self-locking block 12, housing 71, sealed cavity 72, clamp block 73, electrorheological body 74, frame 91, return spring 92, movabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com