Discharging mechanism with air-jet dual-vibration effect for mechanical equipment

A technology of mechanical equipment and discharge mechanism, which is applied in packaging and other directions, can solve the problems of material retention, poor functionality, and single structure of the discharge port, and achieve the effect of accelerating the discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

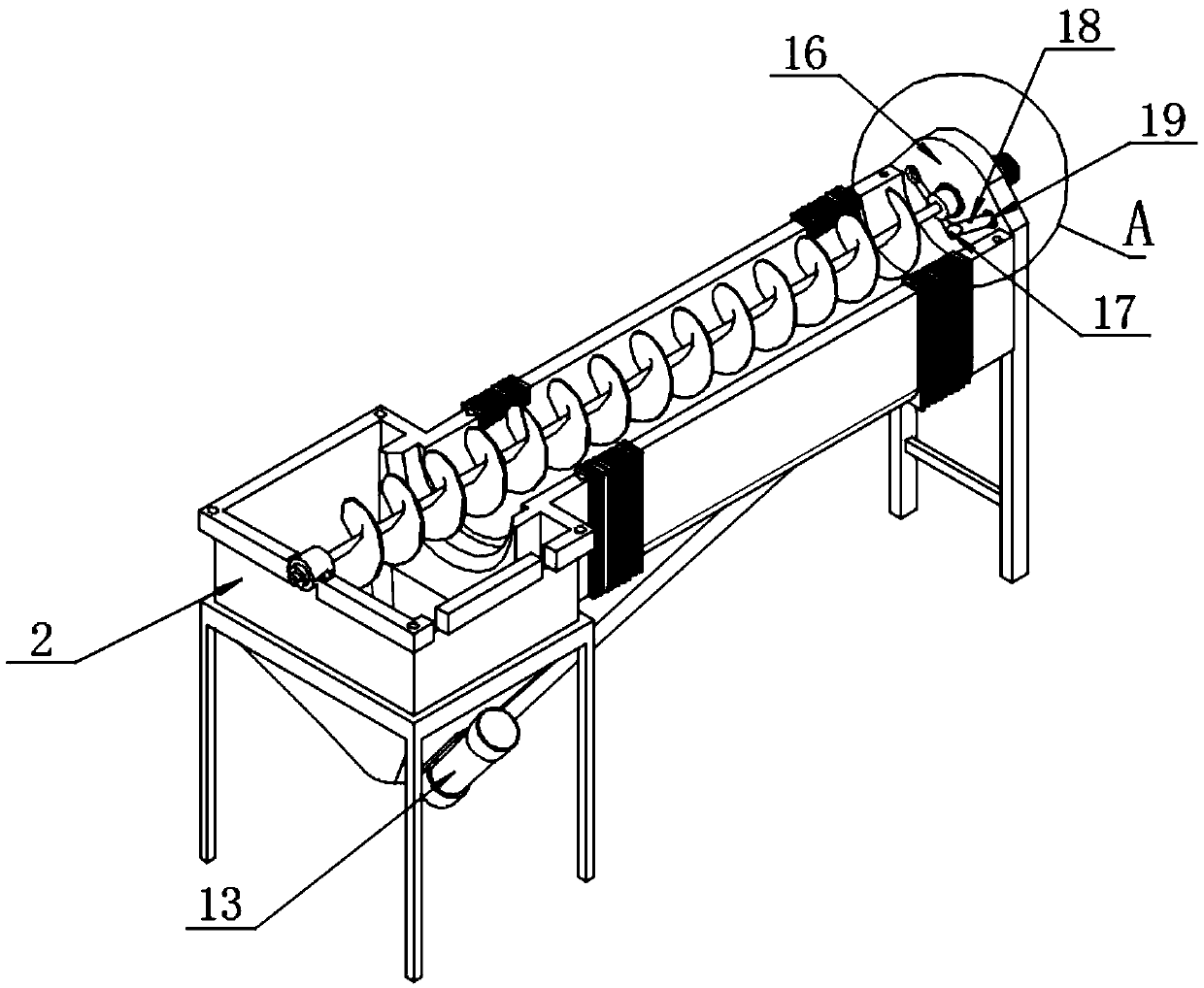

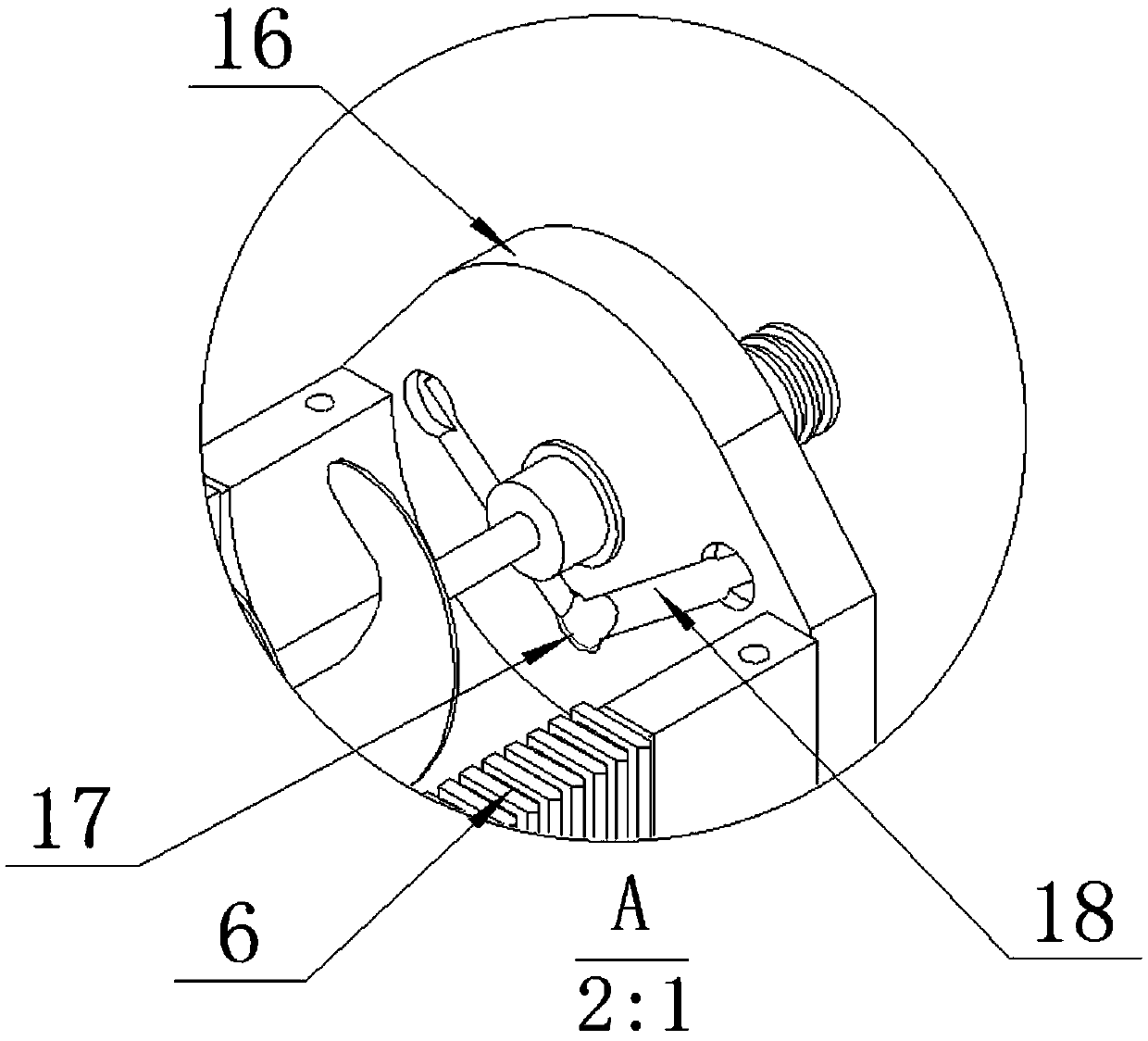

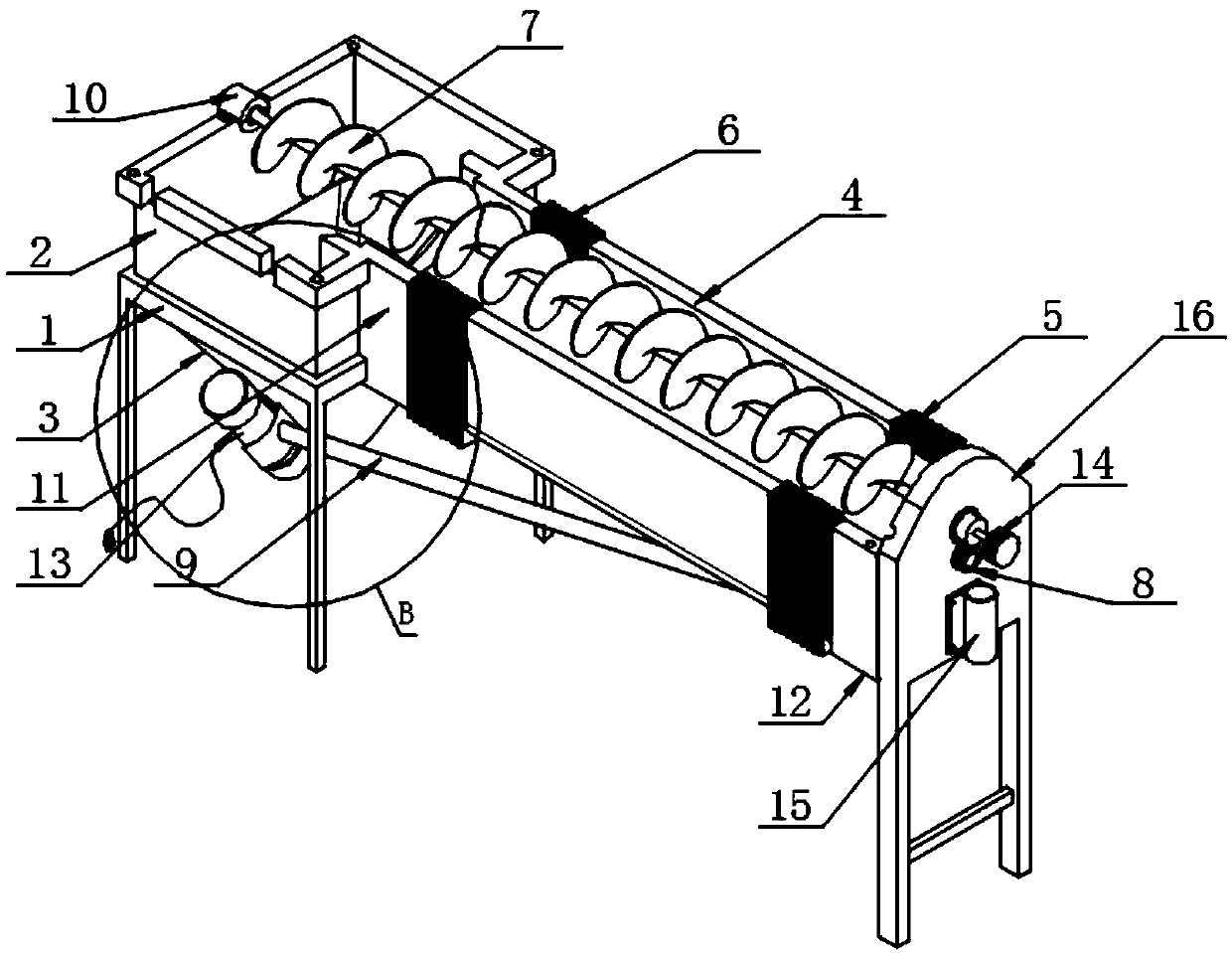

[0028] as attached figure 1 to attach Figure 8 Shown:

[0029] The invention provides a discharge mechanism with jet type double vibration effect for mechanical equipment, including: a left support frame 1, a filling port 2, a discharge hopper 3, a hopper 4, a first corrugated seat 5, a second corrugated seat 6, and a hinge cage 7. Flange interface 8, connecting rod 9, bearing seat 10, left frame 11, right frame 12, vibration motor 13, pulley 14, trigger frame 15, right frame plate 16, pipe inlet 17, turning groove 18, nozzle placement hole 19, support 20 and external connection pipe 21; the top surface of the left support 1 is equipped with a filling port 2, and the bottom surface of the left support 1 is provided with a funnel-shaped discharge hopper 3, and On an outer wall of the discharge hopper 3, a vibrating motor 13 that is electrically connected with an external power supply is installed; There are a second corrugated seat 6 and a first corrugated seat 5, and a rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com